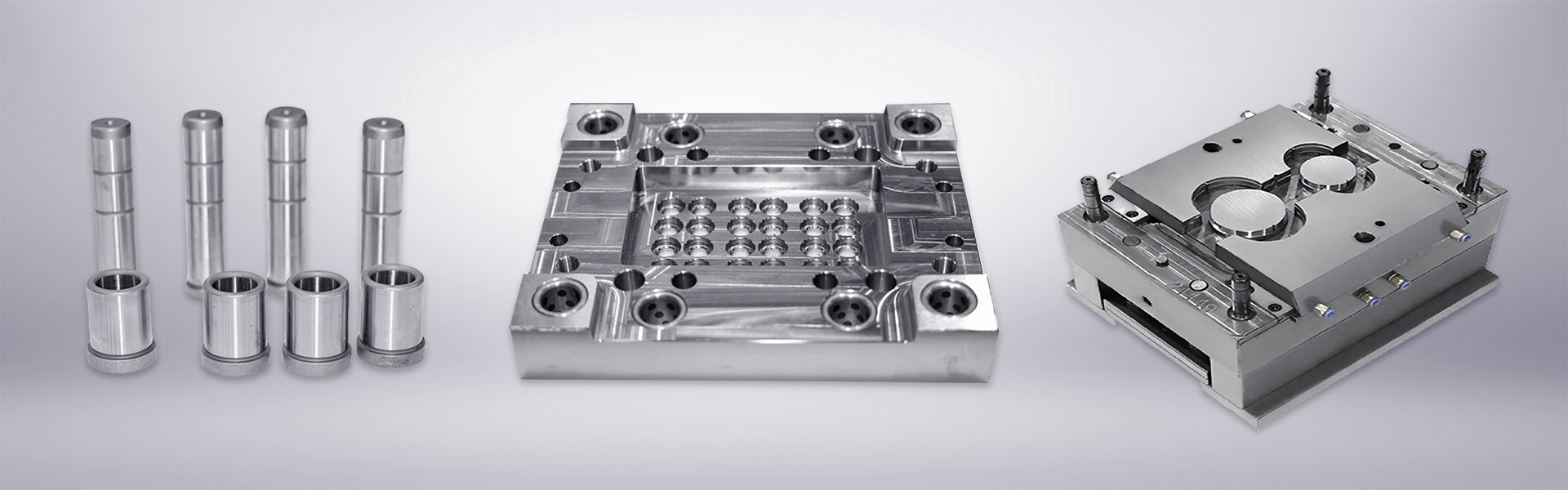

Precision Components, Advanced Processes: The 2026 ITES Industrial Intelligence Summit Officially Launches!

【Introduction】 Industrial Intelligence、Industry Chains

In September 2025, the World Intellectual Property Organization's Global Innovation Index 2025 revealed that the "Shenzhen-Hong Kong-Guangzhou" innovation cluster ranked first globally for the first time. Chinese manufacturing is progressively shifting from leading in scale to excelling in strength, with the Pearl River Delta region maintaining particularly strong industrial momentum.

However, the path of industrial advancement is not without challenges. Constraints in critical bottleneck technologies persist. The core issue being explored by manufacturers is how to concentrate efforts on breakthrough components in specialized fields, using these breakthroughs as catalysts to drive systemic progress across entire supply chains.

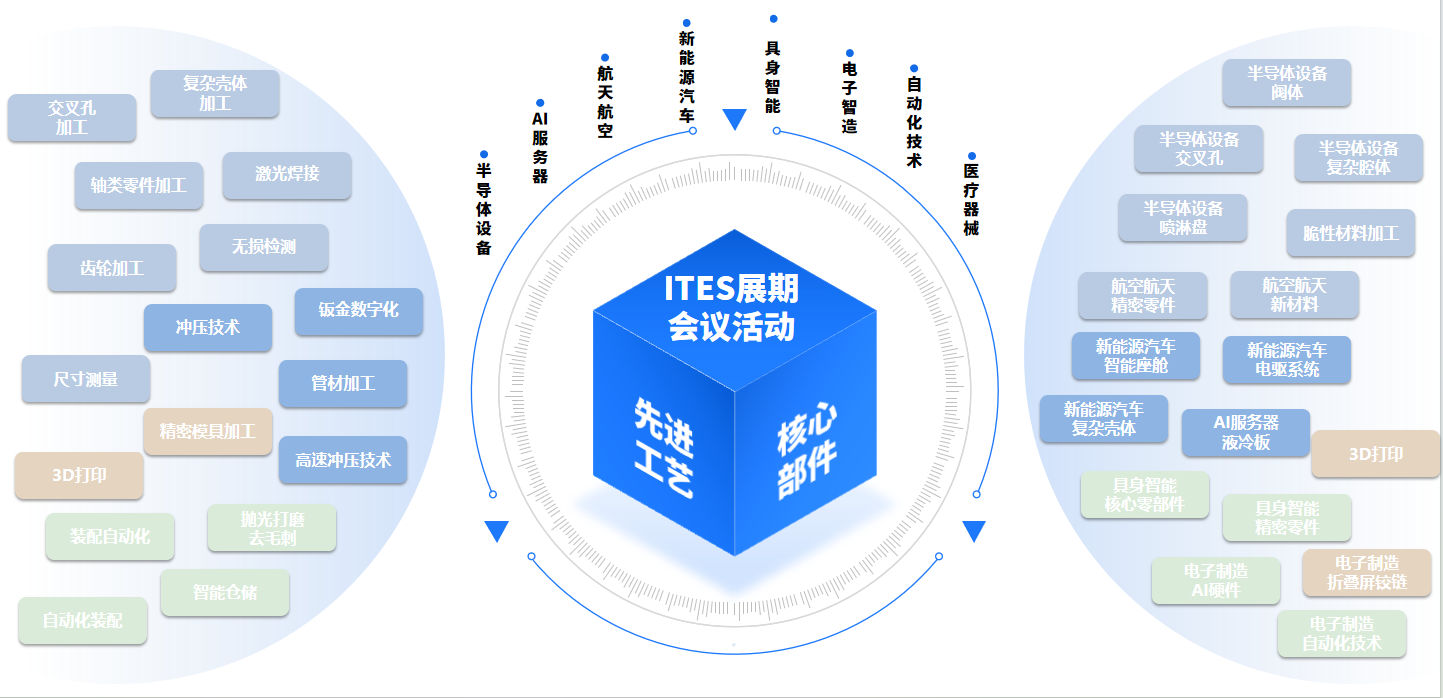

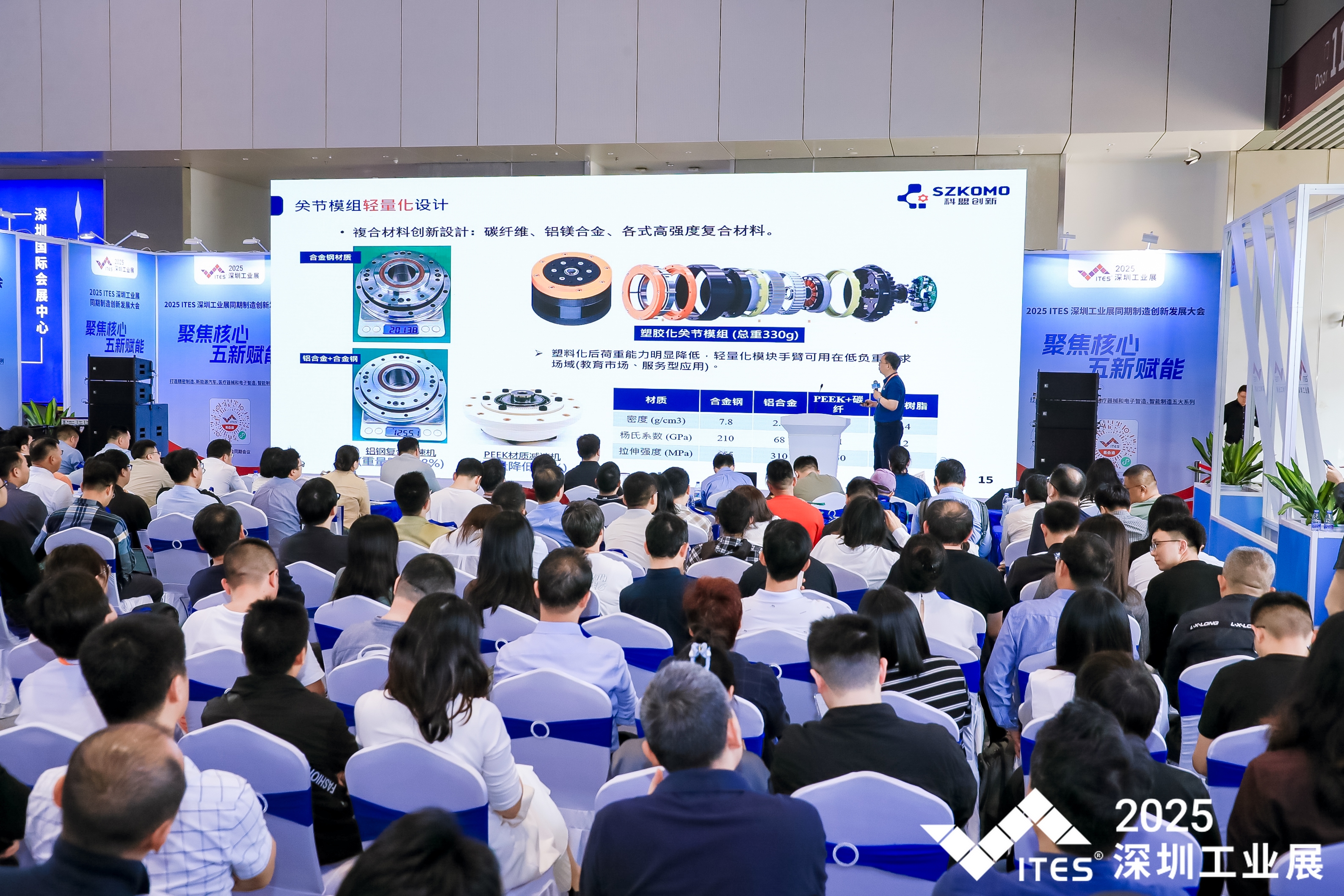

Against this backdrop, the Industrial Intelligence Summit will be held concurrently with the 2026 ITES Shenzhen Industrial Exhibition (March 31 – April 2, 2026). The summit will focus on core product components and the application of advanced processes. Featuring over 80 high-quality thematic forums and gathering more than 450 industry experts and technology leaders, the summit will provide insights into innovative product processes, future market trends, and critical networking opportunities.

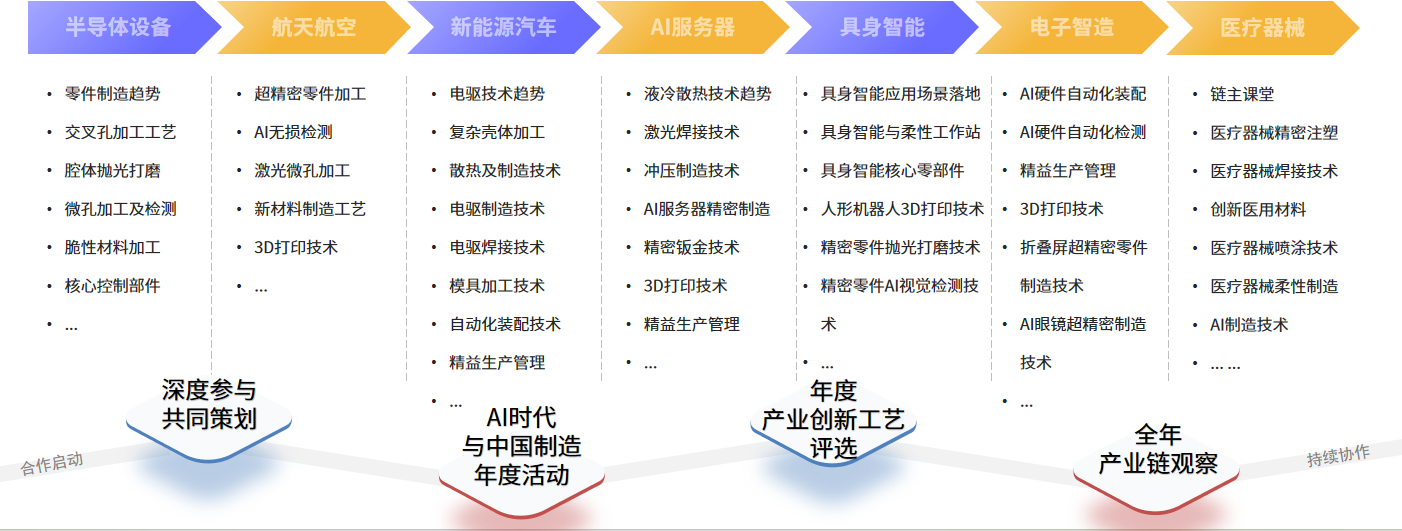

Targeting 7 Key Industry Chains, Addressing Diverse Needs

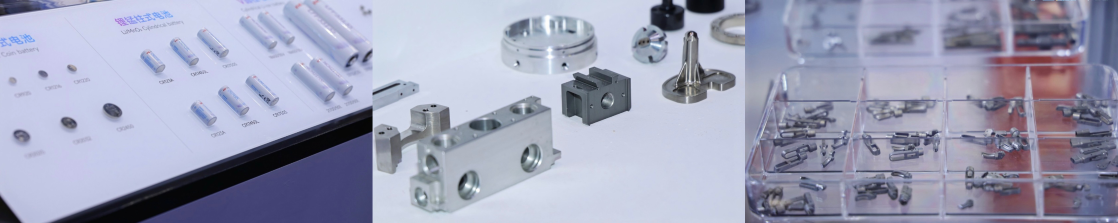

The 2026 Industrial Intelligence Summit delves deep into "Precision Manufacturing," anchoring discussions in both strategic pillar industries and emerging sectors. It covers Semiconductor Equipment, New Energy Vehicles, AI Servers, Embodied AI, Electronics Manufacturing, Medical Devices, and Aerospace, offering technical deconstruction and process insights aligned with real industry demands.

On one hand, strategic emerging industries are flourishing. Sectors like AI servers, Embodied AI, semiconductor equipment, and medical devices are experiencing explosive growth.

• Semiconductor Equipment, a critical field for import substitution, saw a domestic market scale reaching $36.2 billion in the first nine months of this year, ranking first globally.

• The Embodied AI industry is entering a crucial phase of commercialization. The Chinese market is projected to grow to 632.8 billion yuan by 2027. The recent establishment of the MIIT's "Humanoid Robotics and Embodied Intelligence Standardization Technical Committee" accelerates the path towards mass production for humanoid robots.

• AI Servers, as core infrastructure for computing power, are benefiting from explosive global demand. The market is expected to grow to 158.7 billion in China by 2025, potentially reaching 222.7 billion by 2028. Technologies like liquid cooling are rapidly transitioning from optional to essential, driving comprehensive industry upgrades.

On the other hand, strategic pillar industries are showing positive recovery. Industries like new energy vehicles, electronics manufacturing, and aerospace—strategic pillars of the national economy—are finding new growth in niche markets.

• Driven by electrification and intelligent upgrades, China's New Energy Vehicle penetration rate exceeded 50% in 2025, with production and sales potentially setting a new record of 35 million units.

• With breakthroughs in product forms for phones and smart terminals, China's Electronics Manufacturing industry is expected to surpass 17 trillion yuan in scale in 2025.

• The Aerospace industry's market scale is projected to exceed 1.8 trillion yuan in 2025. Developments in derived sectors like the low-altitude economy and satellite internet are creating new growth opportunities.

Addressing hot topics across these industry chains, the summit will gather representatives from over 450 leading companies, including Huawei, Samsung, BYD, XPeng, ACM Research, NAURA, Zhuhai Deding'an, MTU Maintenance, Vertiv, PowerLeader, Lingqiao Intelligent Robotics, and InsiRobotics, to explore pathways for technological breakthroughs.

Focusing on Advanced Processes to Solve Real Production Pain Points

Over the past year, the ITES team has consistently engaged with the front lines of precision manufacturing. We have repeatedly heard about challenges stemming from production, including difficulties in core technology breakthroughs, insufficient supply chain collaboration, and lagging digital-intelligent transformation.

For instance, Huayang Precision Machinery frequently encounters defects like bulges, peeling, exposed copper, burrs, scratches, and pin depressions during the production of metal components such as automotive connectors. Traditional manual inspection struggles to balance efficiency with consistency, severely impacting mass production quality and complaint rates...

To tackle these real-world pain points, the 2026 Industrial Intelligence Summit is structured around the theme of "Core Components + Process Challenges + Solutions," moving advanced processes from theory to practice and providing enterprises with actionable optimization pathways.

• Semiconductor Equipment Forum Series

Will focus on advanced processes such as cross-hole machining for pumps and valve bodies, chamber polishing, leak testing, and micro-hole machining for spray plates. It will deeply discuss the trends and case studies in the localization of semiconductor equipment components, helping enterprises anticipate market and technology directions and providing actionable process optimization insights.

• Embodied AI Forum Series

Spans four key areas: core components for humanoid robots, AI inspection, automated polishing, and additive manufacturing. It aims to address three major pain points: lightweight/miniaturization, precision manufacturing, and cost reduction for mass production. Focusing on mass production via powder metallurgy/3D printing, AI vision for micro-defect detection, and flexible polishing/grinding, and incorporating the latest case studies like miniature reducers and 3D printed force sensors, it will dissect how core technologies can overcome bottlenecks in "precision, lifespan, and cost," enabling the leap from prototype to mass production for humanoid robots.

• AI Server Forum Series

Focuses on four key components in AI servers: cold plates, modules, valve bodies, and sheet metal. It addresses dual challenges in thermal management manufacturing and structural innovation, covering the entire industry chain of liquid cooling, precision structures, and advanced processes. Discussions will explore leveraging innovations in laser welding, 3D printing, and precision sheet metal working to break through challenges like welding highly reflective materials, forming complex flow channels, and manufacturing valve bodies for extreme conditions, capitalizing on the trend where liquid cooling in AI data centers is becoming mandatory.

• New Energy Vehicle Forum Series

Covers multiple powertrain routes including pure electric, hybrid, hydrogen fuel cell, and solid-state batteries, providing forward-looking strategic perspectives and techno-economic analysis. Using core components like motor housings, battery systems, thermal management modules, and high-voltage connectors as entry points, it will delve into new manufacturing paradigms such as integrated die-casting, intelligent welding, and automated production lines for hairpin motors, aiming to empower cost reduction, efficiency improvement, and quality control.

• Aerospace Forum Series

Comprehensively covers topics from machining extreme materials to intelligent maintenance, and from manufacturing emerging aircraft to digital quality control, forming a closed-loop insight system encompassing "new materials, new processes, new equipment, and new operations & maintenance." It will focus on segments like "domestic measurement software," "adaptive machining," and "intelligent decision-making," offering technical references to address challenges such as process bottlenecks, data silos, and lack of standards. The forum will also provide insights into two high-growth sectors: lightweight structures for eVTOLs and intelligent remanufacturing of in-service equipment, offering technological foresight for industries seizing new opportunities.

• Medical Device Forum Series

Centered on areas including in-vitro diagnostics, medical imaging, rehabilitation, medical aesthetics, surgical robots, endoscopes, and the convergence with frontier technologies, this series will drive advanced manufacturing in medical devices from technical perspectives like digitization, automation, AI integration, precision manufacturing, precision injection molding, key components, and new material applications, supporting the localization of core components.

• Electronics Intelligent Manufacturing Forum Series

Addresses challenges in welding highly reflective materials, inspecting smart glasses, and hinge processes across three major application fields: automotive electronics, AI hardware, and foldable screens. Focusing on welding dissimilar materials, nano-level inspection, and mass production via additive manufacturing, and incorporating case studies like Apple's liquid metal hinges and Xiaomi's 3D printed components, it will dissect technologies like ultrasonic welding and laser inspection to promote the scaling of precision manufacturing.

Comprehensive Empowerment, Building a High-Quality Ecosystem

The 2026 ITES Industrial Intelligence Summit rejects theoretical talk. It precisely matches the multi-level, multi-link, and multi-stage needs of manufacturing enterprises, addressing the common bottleneck where companies recognize the importance of certain processes but struggle to find the right path.

Adopting a holistic view of the entire workflow in core component production, the summit meticulously constructs content and connections around "Key Processes, Key Contacts, and Key Resources" to overcome challenges across the full cycle from R&D to mass production. Whether your concern is reliable sealing processes for NEV battery housings, deburring challenges for precision cross-holes in semiconductor equipment, or inspection bottlenecks for complex medical device components—here, you can not only hear breakthrough case studies from leading companies but also directly engage with technical experts and equipment suppliers offering innovative solutions.

The summit will address each stage from design simulation, engineering, process debugging, production optimization to quality traceability, focusing on the most genuine bottleneck points on production lines, helping you bridge the critical gap between technological barriers and efficient mass production.

Addressing the differentiated needs of various functional levels within manufacturing enterprises, the Industrial Intelligence Summit's content is designed to cater vertically—whether you are a decision-maker focusing on strategy and process optimization, an engineer or R&D professional dedicated to technology implementation and process innovation, or a practitioner responsible for supply chain development and procurement execution. We believe you can conduct efficient discussions here on practical issues like "cost, joint R&D, and delivery standards."

We are building a segmented, solution-oriented, and closed-loop environment. You are welcome to bring your strategic layout dilemmas, specific technical challenges, and sourcing needs to the event. Through interaction with "the right people, the right case studies, and the right resources," we hope you will find inspiration.

March 31 – April 2, 2026

Shenzhen World Exhibition & Convention Center (Bao'an)

We look forward to your participation, sharing, and dialogue!