Automation in Stamping: Robots, Feeding Systems, and High-Efficiency Production Lines

【Introduction】 Automation in Stamping: Robots, Feeding Systems, and High-Efficiency Production Lines

Consider the precise, repetitive force of a stamping press. Now, imagine that force directed not by manual intervention, but by a synchronized system of robotics, intelligent feeding, and integrated controls. This is the reality of modern metal stamping automation, a technological shift that moves beyond simple mechanization to create cohesive, intelligent production environments. At ITES China, we observe how this evolution is redefining precision, speed, and reliability in manufacturing. The core of this progress lies in the seamless integration of three critical components: industrial robots, sophisticated feeding systems, and the digital thread that binds them into a high-efficiency production line. For manufacturers seeking a competitive edge, understanding this ecosystem is the first step toward implementation.

.png)

The Core Components of a Modern Stamping Cell

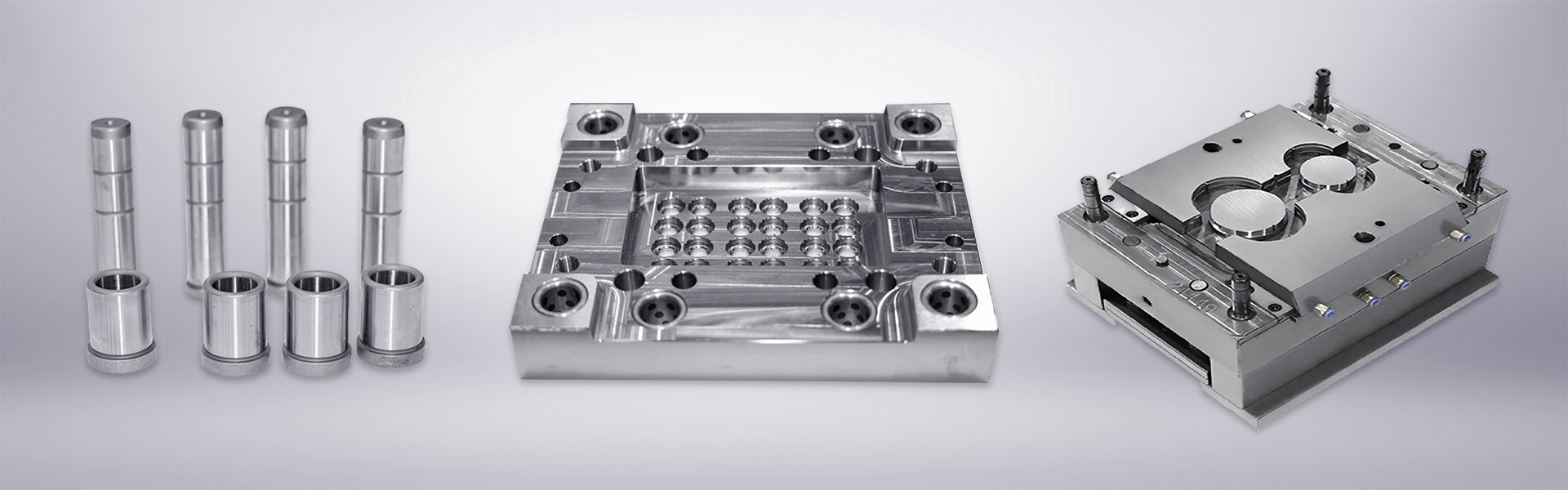

A functional unit of stamping automation is built on specialized components working in concert. Industrial robots, typically six-axis or specialized SCARA models, handle tasks like part transfer, stacking, and loading with consistent precision unmatched by human labor. They interface directly with feeding systems—which range from servo-driven roller feeders to precision vacuum lifts—that ensure material is presented to the die accurately and without pause. This mechanical handoff is managed by a central programmable logic controller (PLC) that synchronizes the press, feeder, and robot, creating a continuous flow. The integration of in-die sensors and simple machine vision for part presence detection further solidifies this reliability, minimizing stoppages and guarding against costly errors. This technical synergy transforms a standalone press into a highly productive cell.

The Integrated Supply Chain and Supplier Advantage in Shenzhen

The development of these complex systems benefits immensely from a concentrated supply chain. In the Pearl River Delta, a hub for advanced manufacturing, access to every tier of the stamping automation ecosystem is streamlined. ITES Shenzhen is situated at the heart of this network. For a builder of automation lines, this means proximate sourcing for servo motors, linear guides, control panels, and specialized grippers. This geographic and industrial concentration reduces lead times for components and facilitates closer collaboration between stamping press OEMs, robotics integrators, and peripheral equipment makers. The result is an accelerated development cycle for tailored automation solutions. At ITES China, we can demonstrate and refine integrated production solutions tailored to specific challenges, such as efficiently manufacturing automotive brackets or electronics enclosures, thereby showcasing their real-world efficiency and cost benefits.

Exploring Advanced Stamping Solutions at ITES China

This year’s event dedicates significant space to these very innovations. The Stamping Technology & Automation Solution zone acts as a comprehensive showcase for the entire spectrum of metal stamping automation. Visitors can expect to see the physical manifestation of high-efficiency production lines, with exhibitors demonstrating live integrations of servo presses with robotic tenders and automated quality checkpoints. The scope is deliberately extensive, covering the full hierarchy of technology. It ranges from the core stamping equipment—servo punch presses and high-speed presses—to the essential automation devices like feeding machines, quick die change systems, and in-line inspection units. Furthermore, the supporting ecosystem of precision molds, lubrication systems, and critical components will be present, providing a complete view of the tools necessary for building a resilient and productive stamping operation.

The shift toward automated stamping is a clear trajectory in precision metal forming. It is a move defined by measurable gains in output consistency and operational safety. The upcoming exhibition provides a unique environment to move from theory to practice, to see the robots, feeders, and control systems that form these lines, and to engage with the specialists who build them. We at ITES Shenzhen have structured this segment to connect global manufacturers with the specialized suppliers and integrated solutions that define the next level of manufacturing capability. The future of production is not just automated; it is intelligently connected, and that future will be on display.