Key Differences Between Industrial Humanoid Robots and Traditional Industrial Robots

【Introduction】 Key Differences Between Industrial Humanoid Robots and Traditional Industrial Robots

Within advanced manufacturing, a distinct category of automation is emerging. Humanoid robots from China and elsewhere represent not merely an evolution of form, but a fundamental shift in capability and application philosophy compared to established traditional industrial robots. For professionals evaluating automation strategy, understanding this distinction is critical. At ITES China, we analyze these technologies through the lens of practical deployment. The divergence extends beyond appearance to core attributes of mobility, environmental interaction, and task generalization, each carrying significant implications for factory integration and return on investment.

.png)

Divergence in Physical Form and Mobility

The most visible difference lies in physical architecture. Traditional industrial robots, such as articulated arms or SCARA models, are engineered for fixed-point operation within a safeguarded work cell. Their strength is unmatched speed and precision for a single, repetitive task. In contrast, a China humanoid robot company typically designs its products with a bipedal or wheeled bipedal form, a torso, and two multi-jointed arms. This anatomical inspiration is not for aesthetics but for function: it allows navigation through spaces built for human workers. Where a traditional robot requires the part to come to it via conveyor, an industrial humanoid robot can move between different stations, use standard tools, and operate in environments where retrofitting extensive fixed automation is impractical. This mobility defines its primary value proposition.

Adaptability Versus Programming

A deeper distinction exists in the approach to task execution. Traditional robots excel through precise, pre-programmed paths. Their world is deterministic, requiring structured environments and exact part positioning. The emerging generation of humanoid robots from China incorporates advanced sensor suites—including depth cameras, LiDAR, and force-torque sensors—paired with AI-driven software. This enables a level of perceptual adaptability. They can identify a component presented in a bin, adjust grip in real-time, and perform assembly tasks that require visual feedback and subtle force control. This shift from strict path programming to goal-oriented, sensor-guided action allows them to handle variability and complex manipulation tasks that are challenging for conventional automation.

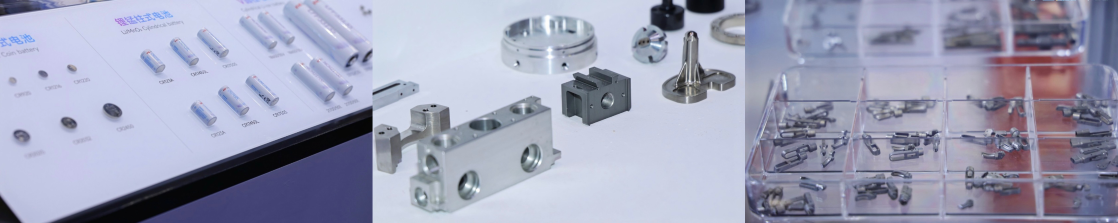

The Supply Chain and Development Ecosystem

The rise of this technology is amplified by a specialized and agile supply chain. The development of a competitive China humanoid robot company relies on access to advanced components like high-torque density actuators, lightweight carbon fiber structures, and sophisticated vision processors. The manufacturing clusters in regions like the Greater Bay Area provide concentrated access to these tiers. For ITES Shenzhen, this ecosystem is a focal point. This density allows for rapid iteration and prototyping, as developers can collaborate closely with suppliers of harmonic drives, embedded systems, and sensor fusion software. This environment supports the vertical integration needed to solve the unique challenges of bipedal stability, power management, and dexterous manipulation, accelerating the path from laboratory prototype to industrial application.

The Humanoid Robot Industry Chain at ITES Shenzhen

This event will feature a dedicated zone charting the entire trajectory of this technology. The Humanoid Robot Industry Chain segment is a direct response to growing industrial interest and the move toward pilot production scales. It is designed to provide a comprehensive view, from core components to integrated solutions. Visitors to ITES Shenzhen can expect to see leading enterprises showcase the fundamental building blocks: next-generation actuators, biomimetic hands, and real-time control systems. Furthermore, the zone will highlight complete robotic platforms and, importantly, their demonstrated industrial applications. This goes beyond concept to focus on use cases in logistics, complex assembly, and hazardous environment tasks, illustrating the practical bridge between humanoid form and industrial function.

The comparison between these robotic paradigms highlights a complementary future. Traditional robots will continue to dominate high-speed, dedicated processes. Industrial humanoid robots, however, offer a solution for flexible, mobile, and dexterous tasks in semi-structured settings. Evaluating their potential requires a clear view of their distinct technical foundations and the supply chain that enables them. Our goal at ITES Shenzhen is to present that full picture. This exhibition zone offers a unique aggregation of the entire industry chain, from the specialists crafting crucial components to the integrators building viable solutions. For manufacturing decision-makers, it presents a necessary opportunity to assess the capabilities, discuss integration pathways, and witness the tangible progress of humanoid robots from China within an industrial context.