Company Introduce

Blum-Novotest GmbH is a renowned manufacturer of innovative and high-precision measuring and testing technology. We develop and manufacture solutions to the highest quality standards and the aim of boosting our customers’ productivity. With technology “Made in Germany”. Each of our products combines experience and expertise with an instinct for forward-looking solutions. A comprehensive service portfolio gives us an innovative edge and our customers the assurance of always receiving the best solution. Every day, more than 650 employees worldwide at Blum-Novotest work to achieve this.

Exhibit brands

Exhibits

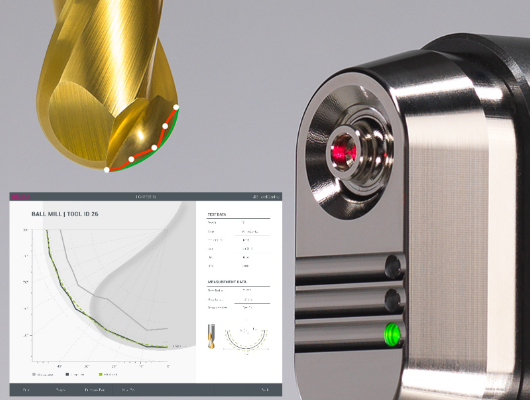

Blum FormControl X Measurement and Automation Software

FormControl X is a user-friendly measurement software designed for machining centers. Combined with Blum workpiece measuring probes, it can perform automatic quality control on workpieces in both single-piece and batch production. It monitors the workpieces based on recorded measurement values, implements statistical process control, and allows reworking within the original clamping device. With FormControl X, users can create complex measurement programs and achieve automation of the machining process through the implementation of a closed control loop. The measurement results can also be utilized for Industry 4.0 applications. This accelerates the manufacturing process, enhances transparency, and optimizes the quality and production costs of the finished products. Graphical display of measurement results in a multi-platform web browser Generation and evaluation of data summaries over a period of time Optimization of the machining process based on statistical assessment Personalized measurement reports that can be exported as documents or in CSV and JSON file formats

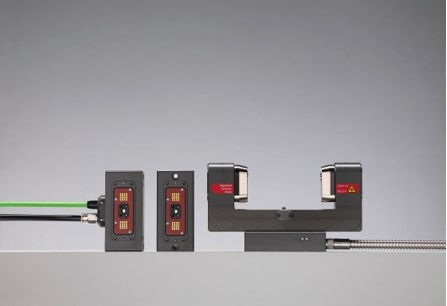

Blum LC50 Digilog 激光对刀仪

The LC50 Digilog is a future-oriented in-machine laser measuring system for CNC machine tools. It is the world's unique laser measuring system for non-contact tool measurement and tool monitoring under the harshest conditions. Thanks to the latest DIGILOG technology, premium laser optics, and the perfected BLUM protection system, it achieves unparalleled speed, precision, and reliability. Tool Measurement with DIGILOG Analog Technology Measurement and Monitoring Time Reduced by Up to 60% Thousands of Measurement Values per Second Process Reliability at a New Level Further Optimized Laser Optics Compact Hardware and Innovative Design

Blum LC-Vision 软件

LC-VISION is an innovative visualization and analysis software developed by BLUM for the DIGILOG laser measurement system. Based on the measurement data, this software can quickly perform visualization and analysis of tools and electric spindles. 3D Tool Shape Measurement Machine Spindle Monitoring and Measurement Historical Measurement Data Statistics and Recording Unified and User-friendly Interface for All Systems

Main products

LaserControl, Tool setting probes, Workpiece touch probes, DIGILOG touch probes, Roughness Gauges, Bore Gauges, Measurement software