- 2026

- 2025

- 2024

- All

- Mainland China

- Taiwan China

- Hong Kong China

- Germany

- Japan

- United States

- South Korea

- Italy

- Switzerland

- Sweden

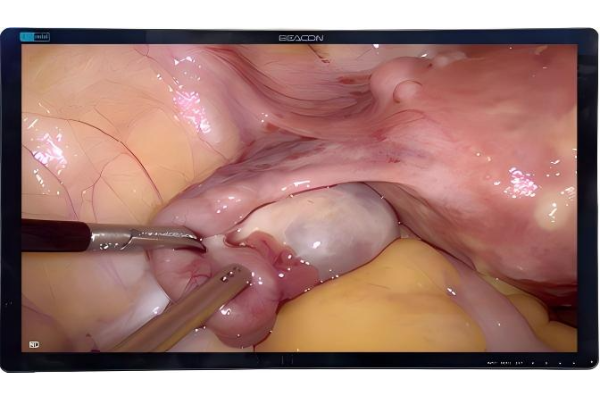

Flexible force control grinding

Beijing Steele CNC Technology Co., Ltd. is a technology enterprise with a history of more than ten years. The founding team of the company is composed of senior mechanical engineers with decades of non-standard design, engineers with decades of sheet metal design and manufacturing, and doctors with doctoral degrees in intelligent control, pattern recognition and intelligent systems. Beijing Steel CNC Technology Co., Ltd. is a full-service automation technology company, providing customers with the best value products and technical support to achieve sustainable industrial manufacturing processes. Beijing Steel CNC Technology Co., Ltd. specializes in polishing technology and hardware surface treatment processing, providing customers with a complete set of solutions for metal surface polishing. Polishing and grinding processing, stainless steel container polishing, sculpture polishing, reactor polishing, head polishing, food machinery polishing, industrial equipment polishing, stirring paddle polishing, non-standard special-shaped parts polishing, etc. The constant force floating device independently developed by Beijing Steele CNC Technology Co., Ltd. has broken the monopoly of foreign products and has a number of research and development achievements. With constant force device as the core, the company has developed a number of robotic automatic grinding supporting products, which are equipped with intelligent compliant system, so as to solve the current pain points of automatic grinding and achieve the goal of robotic grinding instead of manual grinding.

Force control floating grinding head

Beijing Steele CNC Technology Co., Ltd. is a technology enterprise with a history of more than ten years. The founding team of the company is composed of senior mechanical engineers with decades of non-standard design, engineers with decades of sheet metal design and manufacturing, and doctors with doctoral degrees in intelligent control, pattern recognition and intelligent systems. Beijing Steel CNC Technology Co., Ltd. is a full-service automation technology company, providing customers with the best value products and technical support to achieve sustainable industrial manufacturing processes. Beijing Steel CNC Technology Co., Ltd. specializes in polishing technology and hardware surface treatment processing, providing customers with a complete set of solutions for metal surface polishing. Polishing and grinding processing, stainless steel container polishing, sculpture polishing, reactor polishing, head polishing, food machinery polishing, industrial equipment polishing, stirring paddle polishing, non-standard special-shaped parts polishing, etc. The constant force floating device independently developed by Beijing Steele CNC Technology Co., Ltd. has broken the monopoly of foreign products and has a number of research and development achievements. With constant force device as the core, the company has developed a number of robotic automatic grinding supporting products, which are equipped with intelligent compliant system, so as to solve the current pain points of automatic grinding and achieve the goal of robotic grinding instead of manual grinding.

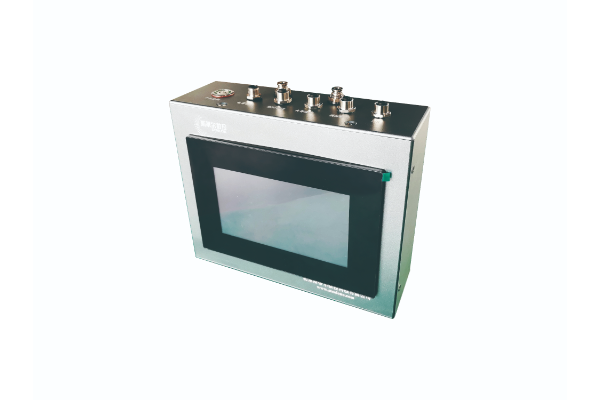

Radial floating spindle

Beijing Steele CNC Technology Co., Ltd. is a technology enterprise with a history of more than ten years. The founding team of the company is composed of senior mechanical engineers with decades of non-standard design, engineers with decades of sheet metal design and manufacturing, and doctors with doctoral degrees in intelligent control, pattern recognition and intelligent systems. Beijing Steel CNC Technology Co., Ltd. is a full-service automation technology company, providing customers with the best value products and technical support to achieve sustainable industrial manufacturing processes. Beijing Steel CNC Technology Co., Ltd. specializes in polishing technology and hardware surface treatment processing, providing customers with a complete set of solutions for metal surface polishing. Polishing and grinding processing, stainless steel container polishing, sculpture polishing, reactor polishing, head polishing, food machinery polishing, industrial equipment polishing, stirring paddle polishing, non-standard special-shaped parts polishing, etc. The constant force floating device independently developed by Beijing Steele CNC Technology Co., Ltd. has broken the monopoly of foreign products and has a number of research and development achievements. With constant force device as the core, the company has developed a number of robotic automatic grinding supporting products, which are equipped with intelligent compliant system, so as to solve the current pain points of automatic grinding and achieve the goal of robotic grinding instead of manual grinding.

01.png)