Company Introduce

Medron specializes in the manufacture and sale of more than 1,000 positioning sensors. The selection factors of the sensor not only include size and shape, but also can be selected according to various specifications such as precision, material, contact force, vacuum environment, heat-resistant specification, wireless type, IO-Link protocol support and the like, so that the sensor is suitable for various occasions and has high versatility. In the manufacturing field, customers have their own unique problems, and we provide customers with a variety of solutions through the combination of ideas and sensors. At Medron, we spend more than 20% of our annual sales on R & D and equipment investment to keep pace with the development of core technologies. As one of the users, we have also introduced 5-axis machine tools, multi-axis lathes and other NC machine tools, automatic assembly machines, inspection devices and other equipment. While using mechanical equipment, we ask ourselves: "What is the problem of mechanical users?" "What kind of sensor would we want if we were ourselves?" So I kept looking for the answer. "The necessity of thermal displacement and preheating operation of machine tools in the morning and evening", "the mixing and consolidation of coolant and chips", "the influence of machine vibration on sensors", etc., will not only use the imported equipment for production activities, but also for improving sensors, improving quality and troubleshooting. In addition to ourselves, we also accumulate expertise through joint development with external stakeholders such as large supporting manufacturers, NEDO and industry-university-research cooperation, as well as by accepting evaluation commissions from customers. These daily efforts have laid the foundation for us to provide rich products and solve the problems of equipment users.

Exhibit brands

Exhibits

Medron High Precision Contact Tool Setter Series

Applied to CNC machine tools to detect tool wear, online automatic compensation to meet the needs of automated production, improve processing efficiency and reduce the generation of defective products.

Precision Pneumatic Workpiece Positioning Sensor DPA

Accurately prevent the occurrence of poor reproduction of CNC machine prices, prevent the production of defective products in the manufacturing process.

Ultra-small high-precision wireless contact probe

On-line detection of product processing size to achieve on-line compensation to prevent the generation of defective products, greatly improving the processing efficiency.

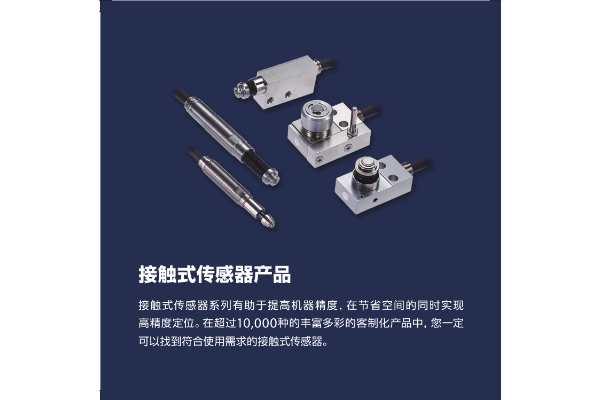

Main products

Airtight detection of sensor probe of tool setting instrument