Company Introduce

Inheritance, innovation and transcendence. Since its establishment in 2009, Shenzhen Hanruikete Precision Machinery Co., Ltd. has been focusing on the research and development of various high-precision CNC machine tools, which are the core functional components of the industrial machine industry. The company covers an area of 3300 square meters, located in the south of Shenzhen New Convention and Exhibition Center, adjacent to Fuhai Exit of Yanjiang Expressway. At present, the company has more than 30 senior technicians of all kinds of machinery, including 6 technical specialist. The main products are UPC series of high precision pitot-static CNC lathes, all of which are supported by hydrostatic pressure. UPMG series products are ultra-precision CNC machine tool series, mainly including single-point diamond lathes, turning and grinding centers, etc. At present, the company's machine tool products are mainly used in 3C electronics, semiconductor parts, optical parts, high-precision molds, aerospace and other high-tech products.

Exhibit brands

Exhibits

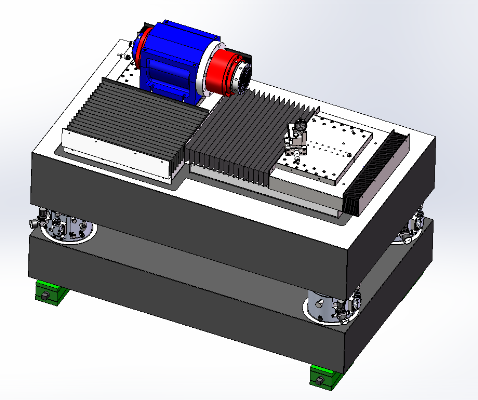

UPC150-200 Standard High Precision CNC Lathe

To meet the internal and external turning of various mechanical parts, roundness deviation < 0.0005 mm, cylindricity deviation < 0.0015 mm, size contour deviation < 0.003 mm. Equipped with high-precision core components: high-precision hydrostatic spindle, high-speed high-precision hydrostatic slipway, hydrostatic tailstock, constant temperature oil cooling system, micron filtration system, SIEMENS 828D system

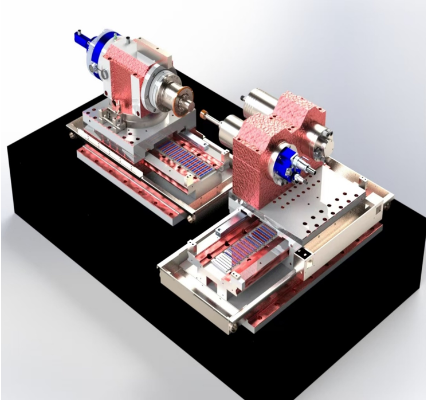

UPIM100A-200 Standard High Precision Internal Grinder

Meet the internal and external grinding processing of various mechanical parts, with roundness deviation < 0.0005 mm, cylindricity deviation < 0.0015 mm, and dimension contour deviation < 0.003 mm. Equipped with high-precision core components: high-precision hydrostatic spindle, high-speed high-precision hydrostatic sliding table, constant temperature oil cooling system, micron filtration system, SIEMENS 828D system

UPIC200A-300 Standard High Precision Follow-up Internal and External Grinding Machine

Meet the internal and external grinding processing of various mechanical parts, with roundness deviation < 0.0005 mm, cylindricity deviation < 0.0015 mm, and dimension contour deviation < 0.003 mm. Equipped with high-precision core components: high-precision hydrostatic spindle, high-speed high-precision hydrostatic sliding table, constant temperature oil cooling system, micron filtration system, SIEMENS 828D system

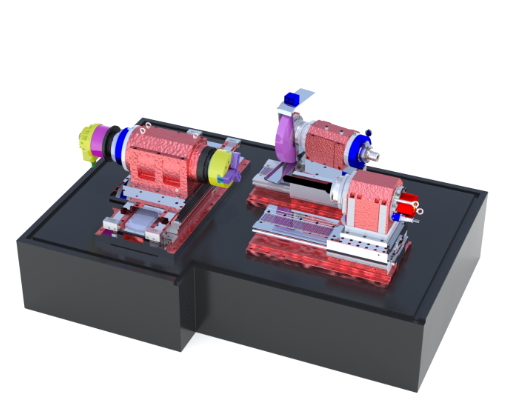

UPD100A single point diamond lathe

To meet the internal and external turning of various mechanical parts, roundness deviation < 0.0005 mm, cylindricity deviation < 0.0015 mm, size contour deviation < 0.003 mm. Equipped with high-precision core components: high-precision hydrostatic spindle, high-speed high-precision hydrostatic sliding table, constant temperature oil cooling system, micron filtration system, SIEMENS 828D system

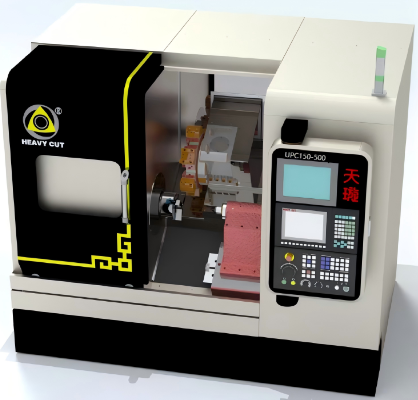

UPC150-500 Standard High Precision CNC Lathe

To meet the internal and external turning of various mechanical parts, roundness deviation < 0.0005 mm, cylindricity deviation < 0.0015 mm, size contour deviation < 0.003 mm. Equipped with high-precision core components: high-precision hydrostatic spindle, high-speed high-precision hydrostatic slipway, hydrostatic tailstock, constant temperature oil cooling system, micron filtration system, SIEMENS 828D system

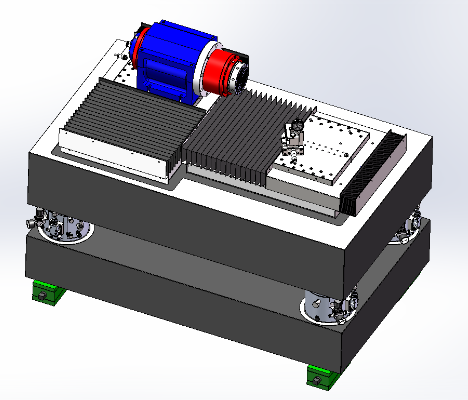

UPD100F Single Point Diamond Lathe

To meet the internal and external turning of various mechanical parts, roundness deviation < 0.0005 mm, cylindricity deviation < 0.0015 mm, size contour deviation < 0.003 mm. Equipped with high-precision core components: high-precision hydrostatic spindle, high-speed high-precision hydrostatic sliding table, constant temperature oil cooling system, micron filtration system, SIEMENS 828D system

Main products

The main machine tool products include high-precision CNC lathes, high-precision five-axis turning and milling centers, high-precision machining centers, ultra-precision single-point diamond lathes, diamond boring machines and ultra-precision turning and milling composite centers, high-precision heavy industrial mother machines, etc.