Company Introduce

Founded in 2013 and located in Guangming District, Shenzhen, Shenzhen Cheery Automation Technology Co., Ltd. is a comprehensive intelligent manufacturing solution service provider integrating R & D, manufacturing, assembly, sales and service. The company is deeply engaged in truss manipulator, joint robot production line, non-standard automation equipment, information intelligent unit, FMS flexible production line and other solutions. At present, it has 2000 + actual customer cases. Its application scope covers new energy, automobile, consumer electronics, household appliances, aerospace, military industry and other industries, and has won recognition and praise from domestic and foreign partners. Since 2017, it has been recognized as a high-tech enterprise in Shenzhen and a "specialized, special and new" enterprise in Shenzhen. It has applied for 120 patented technologies. The company has gathered a large number of professional and technical personnel and formed an excellent management team. With continuous innovation and breakthroughs, the company's business has gradually expanded from the initial single truss manipulator to the research and development and production of information-based intelligent manufacturing systems and other diversified fields, constantly moving to new heights.

Exhibit brands

Exhibits

Information-based intelligent manufacturing system

1. Accuracy: real-time collection, statistics and analysis of data, that is, collection of various data and status information in the whole process from receiving orders to making final products; 2. Open source: application source code is completely open, and collection, change and customization are simple and efficient according to the way of industry suite; 3. Strength: Integrate rich interface protocols, integrate multiple access modes, and realize seamless connection of ERP system, equipment, OA, etc. 4. Economy: The new platform MES can quickly build a collaborative platform to reduce operating costs and maintenance costs;

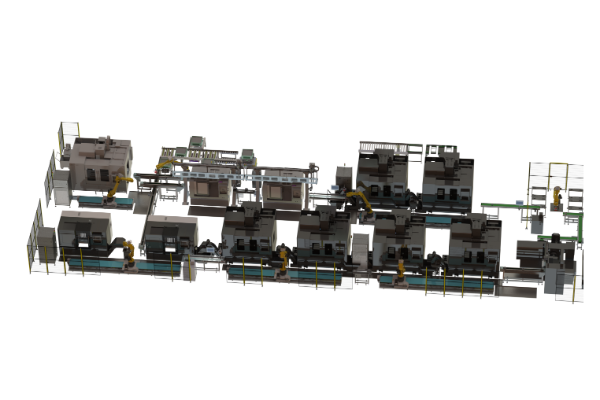

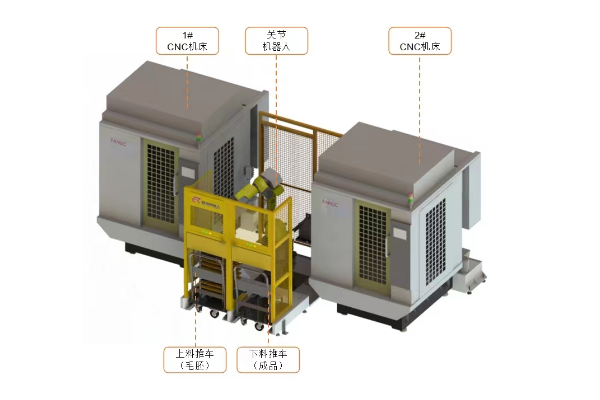

Joint robot aided machining system

1. Robot production line, with the mode of robot + sky rail/ground rail, robot + conveyor line (+ truss manipulator) connected in series to complete the system automation production of the whole production line, customized according to customer needs. And 2, a plurality of truss manipulator and a plurality of joint robots are use to cooperate with each other to operate, so that that action is more flexible, the operation time is greatly shortened by the cooperation of multiple sections during proces, and the refueling rhythm is improved. The customized function program is compiled according to customer requirements and field conditions, so that the purpose is clear, the pertinence is strong, no redundant action exists, the action rhythm optimization efficiency is high, and the equipment production efficiency is high.

Main products

Truss manipulator auxiliary processing system, joint robot auxiliary processing system, joint robot integrated production line, non-standard automation equipment, FMS flexible system production line, information intelligent manufacturing system