Company Introduce

Aoming, founded in 2011, was officially reorganized and registered as "Aoming Measurement and Control" in 2017, specializing in the R & D and manufacturing of optical imaging, machine vision and laboratory precision testing instruments; it is an innovative scientific and technological enterprise with 5 invention patents, 6 utility model patents and 3 appearance patents under application; In the field of measurement, Aoming leads the industry with professionalism, comprehensiveness and innovation, and has the ability of non-standard visual automation development and innovation;

Exhibit brands

Exhibits

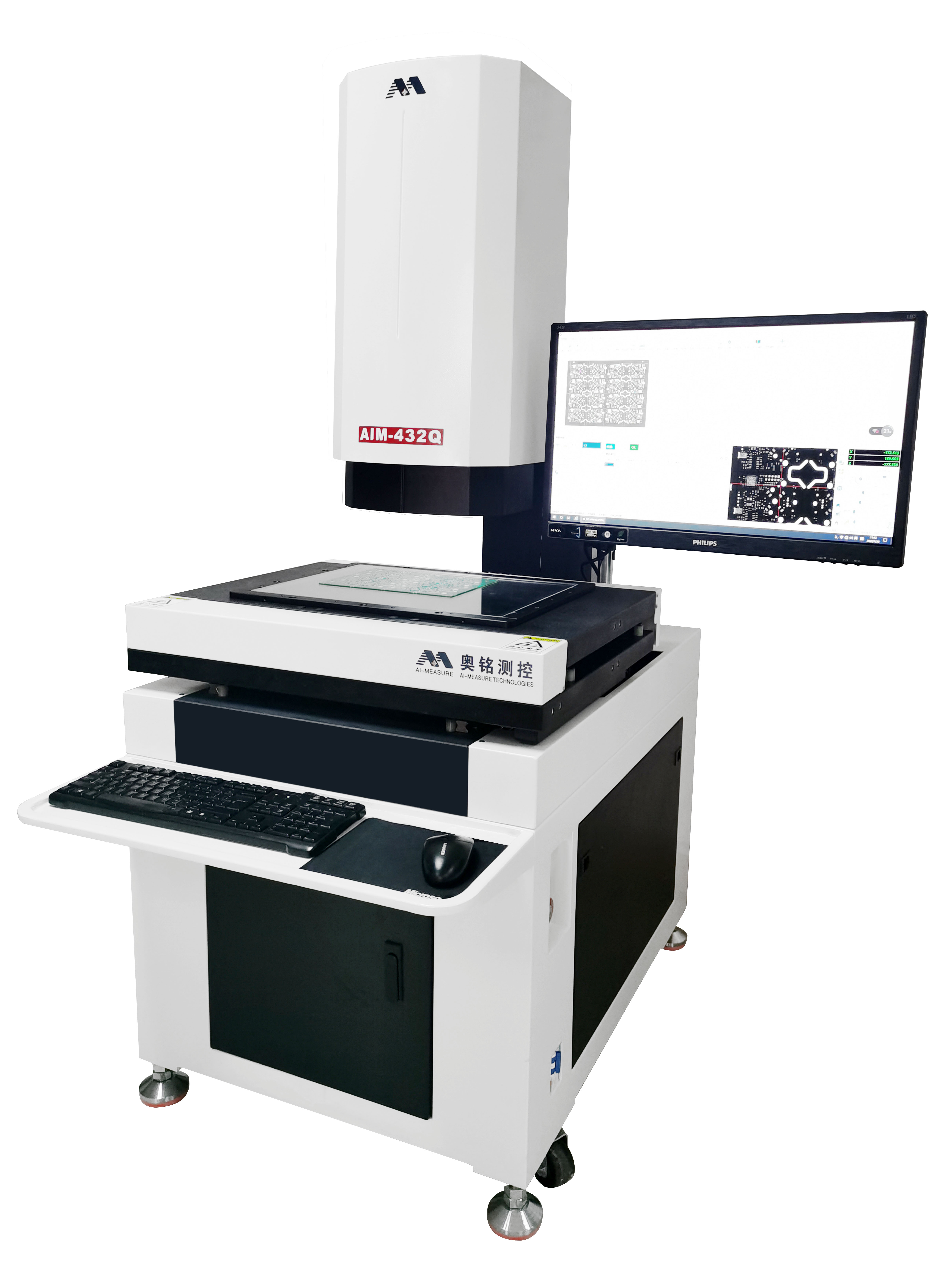

AIM-Q Series Intelligent Rapid Measuring Instrument

1. Accurate flash measurement is triggered, and the measurement efficiency is ten times faster than that of ordinary instruments; 2, that double-telecentric len with big bore and high depth of field realizes clear image in the full field of view without distortion; 3. Automatic image matching function, measuring workpieces can be placed at will without positioning fixture. 4, that measurement of a plurality of position of the workpiece can be realized, the measurement size is increase, and the measurement time is not consumed; 5, a plurality of workpiece can be measured at that same time, and each workpiece doe not need to be measured once; 6, that operation is simple, all measurement process can be quickly completed, and the measurement result can be output; 7, automatic focusing, accurate measurement, measurement results will not vary from person to person; 8. The measurement results can be output to Excel, CAD and other formats; 9. Automatic image splicing can realize large-scale, high-precision and high-efficiency measurement of products.

AIM-R Gantry Automatic Image Measuring Instrument

Gantry structure design, XY displacement does not interfere with each other, better stability, higher precision; ◎ Probe, laser, confocal white light spectrum, etc. can be selected for 3D measurement; ◎ Automatic edge finding, automatic measurement, automatic focusing, automatic program-controlled light source, automatic height measurement; ◎ Structure: fixed gantry type; ◎ Travel: 3020, 4030, 5040, 6050;

AIM-S New Ultra High Definition Image Measuring Instrument

1, XY axis movement positioning 1 UM, never rebound; 4, ultra-high definition imaging effect, while maintaining high frame rate movement without delay; 2. Full-screen and half-screen measurement can be switched freely, and alignment is more accurate; 5. Z-axis "zero segment difference" patent, step concentricity size is more accurate; 3. Light source knob program-controlled double dimming technology, with higher degree of freedom; 6. Custom XY coordinate export function, which can import customer reports in real time;

AIM-T Series Special Image Measuring Instrument for Cutting Tools

1, XY axis movement positioning 1 UM, never rebound; 4, customized optical system, higher tool definition, more expressive force; 2. Special fixture for cutter, more convenient operation and more accurate measurement; 5. Z-axis "zero segment difference" patent, more accurate step concentricity size; 3. Light source knob program-controlled double dimming technology, with higher degree of freedom; 6. Custom XY coordinate export function, which can import customer reports in real time;

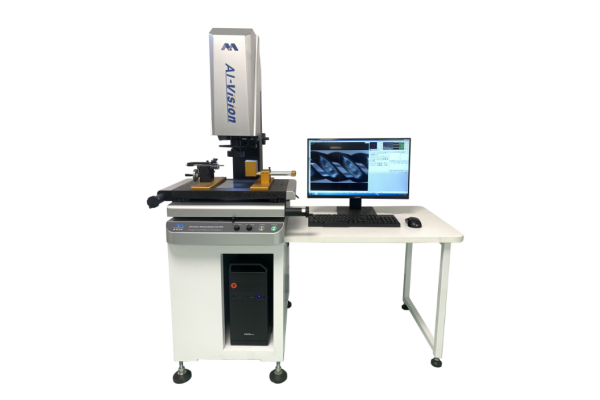

AI-V Series Intelligent Optical Detector

1. that limit of the traditional optical image measurement is broken, and the super-large zoom ratio enable the measurement range to be wider; 2. Ultra-high definition optical imaging with multi-angle multi-division ring LED light source irradiation, so that the image edge contrast is higher, the automatic edge search is more accurate, the degree of automatic measurement is higher, without manual intervention; 3. It has the function of one-key positioning, automatic product identification, automatic matching, simultaneous measurement of multiple products, batch measurement of products, over-tolerance re-measurement and other functions. 4. AI-VM intelligent optical detector has the function of non-reference detection, which can quickly and automatically locate and measure some special-shaped, thin and light products that can not be made into fixtures. 5. Powerful visual and software functions can greatly improve the automatic detection rate, reduce the manual workload, reduce the misjudgment rate, and have the functions of review and retest, which can retest the edge of each element, and have a strong human-computer interaction function, which can give command prompts in the measurement process, such as turning over the workpiece, replacing the product, text, etc. Prevent foolishness and reduce misoperation of workers; 6.. AI-VM can be docked with laser system and 3D probe system, and can perform 2D and 3D simultaneous rapid detection on products; etc.;

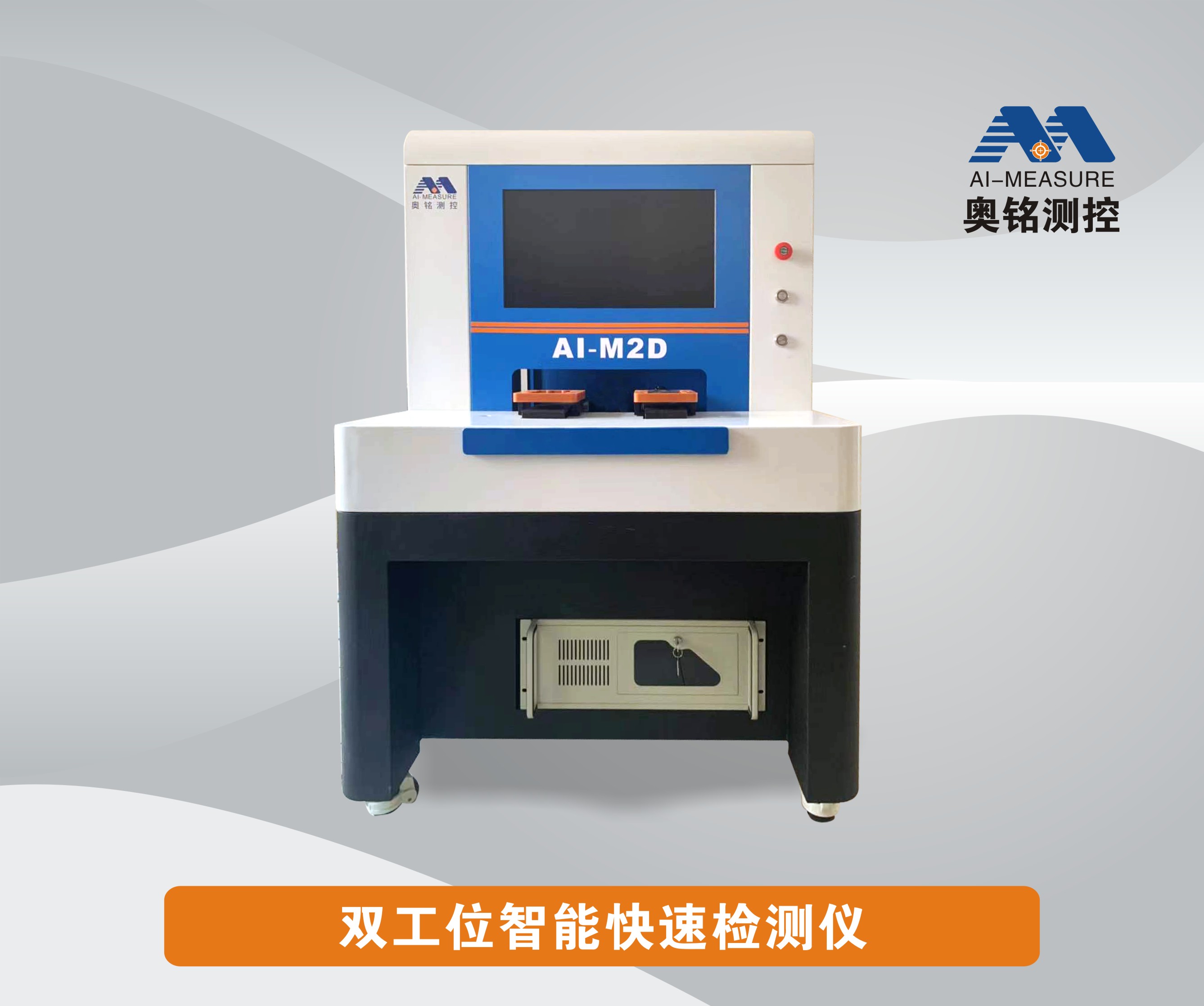

Double-station intelligent rapid detector

◎ Double-station design, one in and one out measurement, no need to wait for one more second; ◎ Conform to the human body design, which can improve the detection efficiency without increasing the strength of personnel; ◎ Full automatic detection, without manual intervention; ◎ 2D contour size detection and 3D arc height measurement can be performed; ◎ It is mainly applicable to the measurement of back cover and middle frame of 5G mobile phone;

AIM-P High-end Automatic Image Measuring Instrument

◎ Linear guide rail and screw rod transmission structure, high speed; ◎ Probe, laser, confocal white light spectrum, etc. can be selected for 3D measurement; ◎ Automatic edge finding, automatic measurement, automatic focusing, automatic program-controlled light source, automatic height measurement; ◎ Structure: overhanging type, integrated or split type; ◎ Travel: 3020, 4030, 5040, 6050;

AIM-II Series Dual-Field Automatic Image Measuring Instrument

1. The base, column and X/Y platform of the whole machine are made of natural marble, which will never deform, with high precision and strong stability. 2. New streamlined integrated structure design, clean, intuitive, generous appearance, space-saving 3. Adopt Taiwan Shangyin linear guide rail, with large span of guide rail slider (200mm), stable operation and more stable precision. 4. Adopt TBI grinding grade screw rod, low noise, fast running speed (300 mm/s), low noise 5. The bottom light adopts adjustable parallel lens LED cold light source. The outline edge of the product is clearer.

Main products

AIM-P high-end automatic image measuring instrument, tool observation instrument, one-key rapid measuring instrument, optical image screening machine, AIM-H large-range image measuring instrument, AIM-R gantry high-precision image measuring instrument, AIM-TWO dual-lens image measuring instrument, tool detector, assembly line non-standard appearance inspection machine,