Company Introduce

Here is the revised English version with the updated company name: KASUGA's parent company, Standard Jackson Limited, was established in 1984 and is headquartered in Hong Kong. The company specializes in importing advanced machine tools from Japan, Europe, and Taiwan. Following China's Reform and Opening-Up policy, Standard Jackson set up a branch in Dongguan, expanding its business into the South China region and further broadening its service coverage. In 2010, Standard Jackson acquired the renowned Japanese machine tool manufacturer KASUGA, which specializes in producing high-precision CNC machining centers. Its clientele includes major manufacturers in the automotive and aerospace industries. In 2011, KASUGA relocated to Taichung, Taiwan, and established Kasuga Co. In 2019, Standard Jackson established Guangdong KASUGA Precision Machinery Co., Ltd. in Dongguan. This move aimed to further boost domestic sales while strengthening its competitiveness in export-oriented international markets, ensuring the continued growth of its core export business. KASUGA is committed to technological innovation and has introduced a series of internationally leading products: Here is the rewritten version using only English and numerical model names: 5 Axis Machining Center KU22, 65, 92 MF22, 65, 92 Drilling & Tapping Center T500, T700 CNC Double Column Machining Center B2217, 3217, 4226, 5226 Vertical Machining Center V50, V70, V80, V100, V110, V120, V140, V160, V200 Box Way Machining Center Q80, Q100, Q120, Q140, Q160, Q200

Exhibit brands

Exhibits

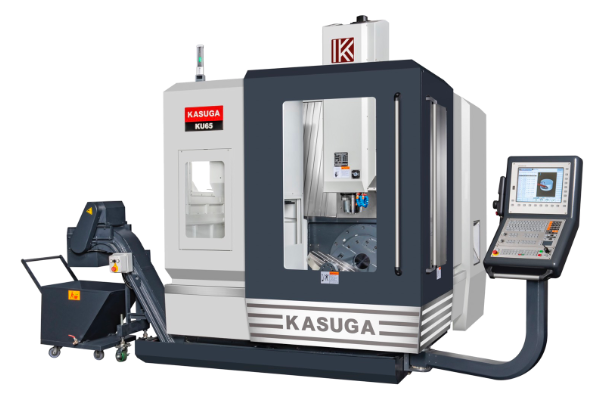

5 AXIS MACHINING CENTER

The KU65 is a high-performance vertical 5-axis machining center designed for high-precision and complex part machining, widely used in aerospace, automotive manufacturing, medical equipment, and energy industries. Its features include: High Precision and Versatility: Supports complex shapes and high-precision machining, suitable for various materials and industries. Optimized Structural Design: C-frame structure with thick ribbed walls provides high rigidity and stability, reducing vibration and improving accuracy. Efficient Production: Equipped with a fast tool-changing system (2.3 seconds), intelligent tool management, and non-contact measurement to reduce scrap rates. 5-Axis Performance: B-axis (-50° to +110°) and C-axis (360° rotation) with high positioning accuracy and a load capacity of up to 300 kg. High-Quality Components: Precision ball screws, linear guides, and a high-speed spindle (12,000 rpm, optional 15,000 rpm) ensure fast and accurate machining. Wide Application Areas: Suitable for turbine blades, automotive parts, medical equipment, and energy industry components. Intelligence and Safety: Supports CAD/CAM programming and anti-collision functions, simplifying inclined surface machining. After-Sales Support: 12-month full warranty, on-site training, and 24/7 online technical assistance.

.png)

VERTICAL MACHINING CENTER

The HV70 is a high-performance high-speed machining center featuring a machining range of 755mm×700mm×460mm, with a maximum spindle speed of 20,000 RPM and a worktable load capacity of up to 700kg, making it ideal for efficient machining of medium to large workpieces. Its high-rigidity frame design minimizes vibrations to ensure high-precision machining results, while the high-speed automatic tool changer (ATC) enhances production efficiency. The HV70 is widely applied in aerospace, mold manufacturing, and complex part machining, offering a combination of high speed, precision, and versatility to meet diverse precision machining needs.

V100 Vertical Machining Center

The V100 is a high-performance vertical machining center with a travel range of 1020mm×560mm×575mm. It supports a maximum spindle speed of 12000 RPM and has a maximum worktable load capacity of 700kg, making it suitable for efficient machining of medium to large workpieces. Its highly rigid frame design enhances stability, reduces vibrations, and ensures high-precision machining results. Additionally, the V100 is equipped with a powerful spindle motor (7.5/11 KW) and an efficient feed system to improve production efficiency. The V100 is widely used in precision machining, mold manufacturing, and complex part processing, offering high speed, high precision, and high adaptability, capable of meeting a wide range of machining needs.

Main products

5 Axis Machining Center, Drilling & Tapping Center, CNC Double Column Machining Center, Vertical Machining Center, Box Way Machining Center.