Company Introduce

Guangdong Precise Numerical Control Technology Co., Ltd. was established on March 22, 2016, with a registered capital of 51,385,700 and a total investment of 120 million yuan. The registered address of the company is Shenzhen Qianhai Shenzhen-Hong Kong Cooperation Zone, which covers an area of about 40 mu in Xiegang, Dongguan, and has 90000 square meters of intelligent manufacturing equipment industrial park. It has more than 300 employees and annual sales of about 300 million yuan. In 2018, the company was recognized as a national high-tech enterprise and won the second prize of China Machinery Industry Technology Science Award, the second prize of Guangdong Machinery Industry Technology Science Award and Guangdong Science and Technology Progress Award. The company has obtained 58 invention patents, more than 140 other patents and 60 software copyrights.

Exhibit brands

Exhibits

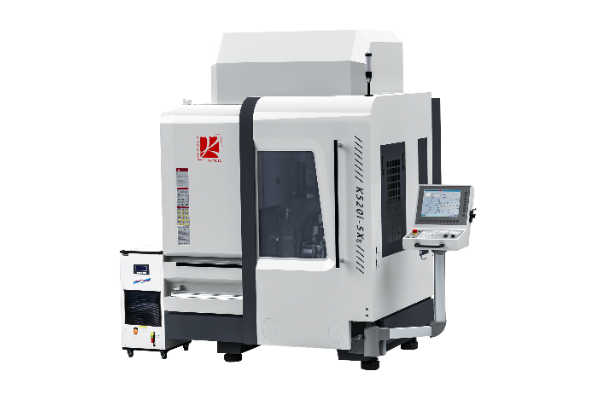

K520i-5Xs 5-Axis High Speed Machining Center

K520i-5Xs five-axis machining center is developed to meet the needs of multi-surface machining of complex parts and realize five-axis linkage machining. It is mainly suitable for five-axis processing fields such as blades, turbines, complex small precision moulds, medical components, aerospace and aviation.

K-540A High Speed Vertical Machining Center

K-540A high-speed vertical machining center adopts natural marble gantry structure bed. After long-term natural aging, the structure is uniform and the linear expansion coefficient is small; It is mainly suitable for high precision mould, copper electrode processing and various occasions with high precision requirements.

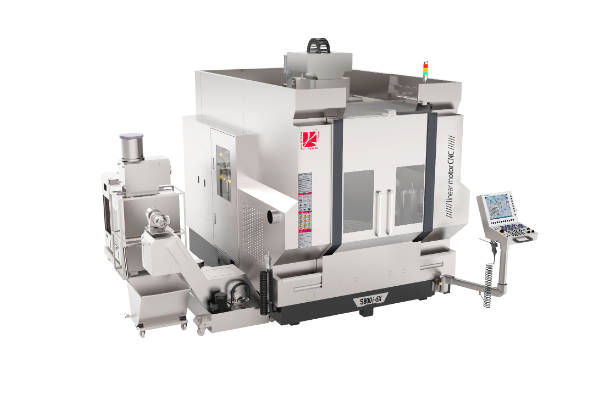

S800i-5X High-speed High-precision Beam Machining Center

The S800i-5X uses a one-piece mineral casting base, which has good shock resistance and prevents vibration interference from affecting the processing. A moving beam type cross beam is adopted, and the cross beam adopts a 45-degree structure, so that the center of gravity is moved backward, and the structure is more stable. Equipped with five swing axes, the swing axis and the rotation axis can rotate along the X, Y and Z axes during machining. Full closed-loop control, all axes are equipped with high-resolution grating ruler; Interpolation control is carried out by using Rhenium Sodium Gram U5E control system. It is suitable for five-axis processing fields such as complex precision moulds, automotive parts, medical parts, aerospace and so on.