Company Introduce

In 2016, Zhuo Yiyan business start. Obtained ZYYTW trademark in 2020. The 2021 became a separate entity. Zhuo Yiyan is not only a product designer and manufacturer but also a user. We are aware of the difficulties in cutting tools and fixtures on the site. We take the actual needs of the site as the starting point, pass on more than 50 years of experience in basic manufacturing industry to meet the actual needs of customers and markets. Division I have developed the current mechanical accessories are: milling machine shank, cylinder clamp, vise, lathe precision six-claw and eight-claw Chuck. In the professional field of different parts, according to their requirements and characteristics to select high-quality materials and the best performance of the heat treatment process and parameters, so that its performance is more stable, more outstanding life, and ensure the precision is ≤0.005 mm. For each mechanical parts are factory quality assurance and traceability through serial number.

Exhibit brands

Exhibits

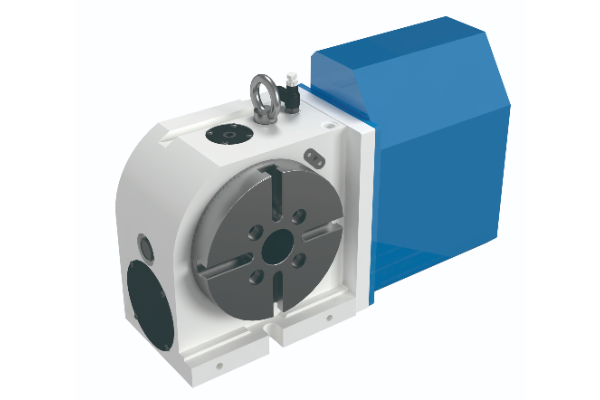

CD roller cam four-axis series

Widely used in a variety of modular machine tools, machining centers Roller cam structure, small wear, fast indexing speed, positive and negative rotation, zero backlash, high positioning accuracy, long service life Through the rotation, the product can be processed on multiple surfaces, thereby greatly improving the processing efficiency and reducing the clamping times Parts with complex or more complex designs can be produced

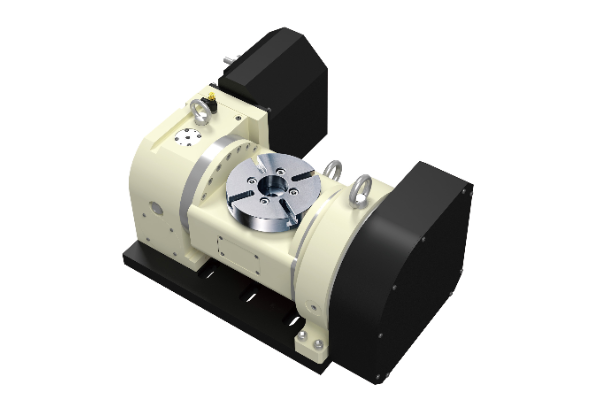

HCD roller cam five-axis series

Widely used in a variety of modular machine tools, machining centers Roller cam structure, small wear, fast indexing speed, positive and negative rotation, zero backlash, high positioning accuracy, long service life Through the rotation, the product can be processed on multiple surfaces, thereby greatly improving the processing efficiency and reducing the clamping times Parts with complex or more complex designs can be produced

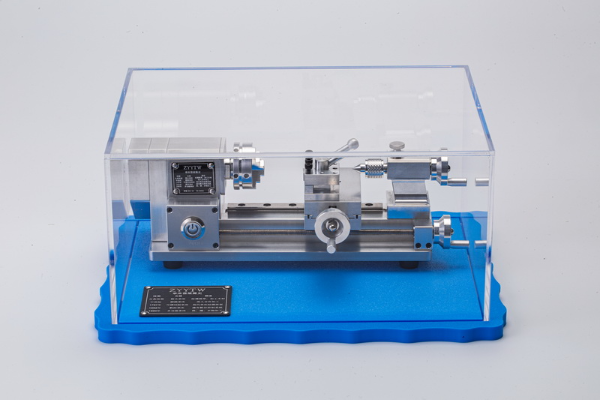

MINI small lathe

It has the advantages of compact size, storage and playback of music. It retains the mobility of the original X, Z axis and tailstock. It has 120MB of song memory, which can store about 50 songs.

CNC tailstock

Body material > The body is made of high-quality alloy structural steel 42CrMo + roughing + tempering heat treatment Material of main parts > The main shaft is made of high-quality steel of Great Wall Special Steel + heat treatment + grinding. Standard accessories > Japanese NSK double cone bearings, oil seals and other accessories Comprehensive accuracy > Runout within 0.005 mm

Precision vice

Material >. Adopt SK2 die steel conforming to Japanese JIS G4401standard Process >. Roughing + heat treatment + deep cooling + grinding + assembly Accuracy >. The verticality of three sides can be within 0.005 mm.

Tool holder of milling machine

Material: SCM415 carburized steel imported from Datong, Japan Process > Quenching and tempering + turning and milling machine roughing + carburizing + cryogenic + finish turning + grinding process Accuracy > fitting area of more than 90%, composite runout of 5 times diameter of less than 0.005 mm, 100% inspection of dynamic balance

CNC Lathe/Milling Machine Precision Six-jaw, Eight-jaw and Inner Support Chuck

Material > Made of high quality steel of Great Wall Special Steel + heat treatment + grinding Process > Machining process of turning and milling machine roughing-heat treatment-finish turning-inner and outer diameter grinding Accuracy > Repeated installation runout ≤ 0.005 mm Use > Thin-walled parts processing essential to ensure product roundness and concentricity

Main products

Custom machine parts design and production conventional machine parts design and production technology consultation and support product application teaching and service