Company Introduce

Phoenix Contact (China) Holding Co., Ltd. is one subsidiary of German Phoenix Contact GmbH & Co. KG in China and serves as a Center of competence for the Phoenix Contact Group in the Asia-Pacific region. Entering China in 1993 and headquartered in Nanjing, the company has more than 2,000 employees at present. The company has so far established more than 20 regional offices and more than 100 distribution facilities in various areas throughout China. For faster response to customers’ needs, it has respectively set up Beijing Center, Shanghai Center, and Guangzhou Center.

Exhibit brands

Exhibits

Efficiency In Cabinet Building - Comprehensive Improvement of Control Cabinet Assembly Efficiency

Control cabinets are the core of modern industrial automation systems, providing reliable protection for internal electrical components and ensuring a continuous supply of power for stable system operation. With the rapid development of automation, the manufacturing of control cabinets currently faces two major challenges: Data Consistency: Optimizing the collaboration between planning and manufacturing can significantly reduce the production time required for control cabinet manufacturing. The prerequisite for achieving this goal is to provide a continuous data flow, complete product data, and seamless system interfaces. Scalability and Modularity: In the process of control cabinet manufacturing, whether adopting highly standardized production or single-piece production, the potential for cost-effectiveness and flexibility can be maximized. Whether it is easy-to-use identification solutions, ergonomic handheld tools, or automated tools, we always adhere to the concept of modular combination and personalized expansion, providing you with full support throughout the process. The Phoenix Contact Efficiency In Cabinet Building solution can cover design, process, material preparation, wiring, identification, installation, inspection, and other aspects.

ESSENTIAL edition 意选系列产品 —— 一贯品质,满意之选

Description: Phoenix Contact, based on market segmentation and customer applications, has launched the ESSENTIAL edition product series through relentless innovation and a pursuit of excellence, meeting customers' needs for precision components. The product portfolio covers multiple fields, including connection technology, electronic components, industrial power supplies, and surge protection, with a unified design style, a wide range of products, and ease of selection and use. Connection Solutions: Terminal blocks inside the cabinet, such as TBI and TBP terminals, and UM terminal identification. Heavy-duty connectors outside the cabinet, SAC signal and data cables, and SACC circular connectors. Electronic Interface Solutions: ECOR relays, MINI MCR-BL isolators, MR-ES monitoring relays, TR-ES time relays, CT-ES current transformers, and EE EMpro energy meters, providing complete and cost-effective control and monitoring of equipment. Industrial Power Supply Solutions: EE PS switch-mode power supplies can meet the diverse power supply needs of customers in industries such as mechanical manufacturing and building installations. System Protection Solutions: VAL-MS-EE surge protection, SP-EE-TT signal surge protection, and EMC-EE filters offer specialized surge and electromagnetic interference protection solutions for different application scenarios.

Push-X Spring Terminal Blocks

Description: With the rapid development of intelligent and automated industrial equipment, higher demands are placed on the convenience, safety, and reliability of connectors. Phoenix Contact has introduced a new generation of wire terminal blocks using Push-X connection technology. A New Wiring Experience: Push-X spring terminal blocks are compatible with various types of wires (such as solid wires and multi-core flexible wires). They can achieve a reliable connection with minimal insertion force, making wiring easy and effortless. Improved Wiring Efficiency: Wires can be connected directly without cold crimping or tools, saving a significant amount of installation time. Compared to screw connections, Push-X technology can increase wiring efficiency by approximately 50%. New Member of the CLIPLINE complete Series: The Push-X terminal blocks share common identification, bridging components, and test accessories with other products in the Phoenix Contact CLIPLINE complete series. This reduces material management costs and simplifies selection and application.

High System Availability Electrical Comprehensive Solution

Description: With the increasing levels of electrification, networking, and automation, people are becoming more reliant on reliable electrical system solutions. To efficiently and safely use electrical equipment, Phoenix Contact offers a comprehensive solution for high system availability, which includes: protection against surge voltage interference, electromagnetic interference (EMI), power monitoring and metering, stable intelligent power supply, and intelligent overcurrent protection for branch circuits. Protection Against Electromagnetic Interference – EMC/EMI Filters Frequency Range: Filters out interference in the 9 kHz to 30 MHz range. Noise Attenuation: Strong noise attenuation capabilities. Current Range: Available in 0.5-400A, with 600-800A versions soon to be launched. Efficient and Reliable Power Supply – TRIO3 Power Supply Optimized Structure: The TRIO3 power supply is optimized with higher integration of components. Integrated Electronic Circuit Breaker: An integrated electronic circuit breaker version is available, offering power supply and overcurrent protection in extremely narrow spaces. Multi-color LED & Alarm Dry Contacts: Equipped with multi-color LEDs and alarm dry contacts, with additional support for IO-LINK communication. Intelligent Protection for Multiple Loads – Electronic Circuit Breakers Precision Overcurrent Protection: Real-time detection of circuit loops. Remote Signaling & Monitoring & Predictive Maintenance: Features remote signaling, alarm, remote monitoring, and predictive maintenance capabilities. Channel Options: Available in 1/2/4/8 channels, with each channel offering 0.1-20A options. These can be combined with power supplies to form a modular power and protection solution.

Thin-profile IO Series Enclosures

Description: To meet the domestic demand for small and medium-sized PLC products that balance cost-effectiveness and high quality, Phoenix Contact has launched the Thin-profile IO Series Enclosures. This product series includes CPU module enclosures (with expansion cards), coupler module enclosures, and IO expansion module enclosures. Designed, developed, and manufactured by the Chinese team, these products can quickly respond to the needs of domestic customers and offer customized solutions such as printing and color modification. Inter-module communication: Utilizes 8-bit double-sided clamp terminals with a three-way terminal structure, which is more resistant to vibration and provides stable and reliable performance. 18-bit direct-insertion spring terminals: Tool-free installation for efficient connections. Self-resetting function of the rail clip: Ensures easy and secure mounting on the rail. Simple structure: Facilitates production assembly and on-site maintenance. Optional rail grounding spring: Compliant with THR (Through Hole Reliability) process requirements.

MAX100 PLC

Description: The MAX100 PLC is a high-performance, cost-effective controller specifically designed for Chinese customers, suitable for small and medium-sized automation systems. It features powerful computing capabilities, motion control functions, and support for multiple communication protocols, easily meeting the diverse functional requirements of industrial sites. Fastest cycle time of 1ms, supporting up to 16 real-time tasks. Compliant with IEC61131-3 standards, designed specifically for Chinese engineers. Rich communication interfaces: Equipped with 2 Ethernet ports, 2 serial ports, and 1 CAN port. Configuration wizard for quick setup of communication and axis control functions, with built-in communication debugging tools. Code-free implementation of communication functions, facilitating efficient development. Supports USB power supply for program downloading, eliminating the need for an external power source.

Next-Generation Wi-Fi 6 Industrial Wireless Ethernet Communication Module

Description: The next-generation Wi-Fi 6 industrial wireless Ethernet communication module is based on the Wi-Fi 6 (IEEE 802.11ax) standard and utilizes the latest wireless LAN technology. It significantly enhances bandwidth and data transfer rates, providing the highest levels of security and reliability to meet the growing demands of modern wireless communication. Supports 2.4GHz and 5GHz bands Compliant with Wi-Fi 6 (IEEE 802.11ax) standard OFDMA technology: Higher transmission efficiency, supporting more wireless devices. MU-MIMO technology: Greater communication bandwidth, enabling connections to high-bandwidth devices. Supports industrial Ethernet protocols such as PROFINET and EtherNet/IP Supports fast roaming: Improved real-time communication and stability. Supports TWT (Target Wake Time): Effectively reduces device power consumption and extends battery life.

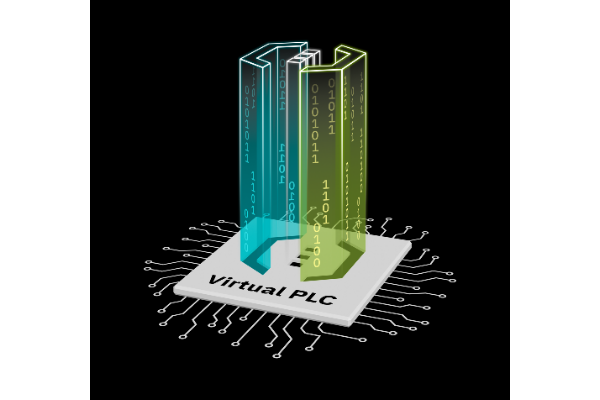

Virtual PLCnext Control

Virtual PLCnext Control is a new-generation open virtual control software solution launched by Phoenix Contact. Based on the Phoenix Contact PLCnext open automation platform and combined with software virtualization technology, it provides a flexible, scalable, and cost-effective industrial-grade control solution. It is committed to creating a new open automation platform where hardware provides resources and software defines automation.

Main products

As a well-known brand in the field of global electrical connection and electronic interface, industrial automation, Phoenix Contact has always put an innovative spirit into practice. Followed by changes in the market, driven by customer demand and industry application, Phoenix Contact provides customers and partners with practical and effective solutions, and also specialized, refined, and differentiated devices, systems, and solutions including industrial devices and electronic technology, device connection technology, industry management and automation.