Company Introduce

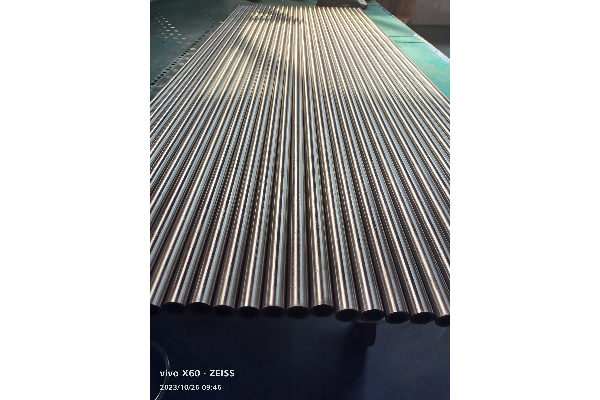

Vacuum quenching and vacuum tempering of metallic materials: hardening and tempering: carburizing: bright annealing of soft magnetic materials: nitriding, blackening, solid solution, Industrial robot ball screw tube/bar and parts precision processing: automation equipment parts, gear transmission, automotive parts, etc., using ultrasonic induction quenching equipment and vertical induction quenching equipment, so that the workpiece layer gradient reaches HRC, 50-62, improve the wear resistance of the workpiece. Failure analysis of parts, metallographic examination and analysis. Testing of mechanical properties of metallic materials.