Company Introduce

Anhui Cosmos Machine Tool Co., Ltd. (BYSK Baoyu CNC) is a comprehensive enterprise integrating research and development, production, sales and service of CNC systems, CNC machine tools, automated production lines, industrial robots, Internet of Things and other products. Headquartered in Zhejiang (Zhejiang Baoyu CNC Machine Tool Co., Ltd.), it has a manufacturing base covering an area of 35,000 square meters in Taizhou; it has opened an independent research and development center in Hangzhou (Hangzhou Auger CNC Technology Co., Ltd.) and added a manufacturing base covering an area of 100,000 square meters in Guangde, Anhui (Anhui Cosmos Machine Tool Co., Ltd.) in 2013. The company specializes in the production of CNC center-moving machines, high-precision row cutter CNC lathes and turn-milling composite centers, turn-milling composite machine tools, inclined bed CNC lathes, automatic double-spindle lathes and other products, the full range of products using absolute value servo, Ethercat bus protocol. The products are widely used in communication, 5G products, household appliances, military industry, aerospace, medical equipment, automobiles, plumbing, micro-shaft, optical instruments, connectors, clocks and watches, glasses and various hardware accessories and other industries. The products with high cost performance are ideal equipment for mass automation production in all walks of life.

Exhibit brands

Exhibits

B20 double-axis numerical control center walking machine

B20 double spindle CNC lathe adopts four-axis four-linkage, with high stability, high precision and easy operation. According to the needs of parts processing, the side power head can be selected to realize the automatic production of drilling and milling. The structure design is stable. The high-quality cast iron bed has strong rigidity. The automatic feeder is configured to realize automatic continuous processing.

B07 Double spindle Swiss type automatic lathe

B07 Headstock Movable CNC Lathe: It is a processing equipment with high precision, wide range and high practicability. This kind of machine tool is suitable for mass, multi-variety and high-precision processing tasks of "slender shaft" parts with large length-diameter ratio and "small" and "special-shaped" parts. Its processing range is widely used in medical, aviation, aerospace, military, automobile, motorcycle, communication, refrigeration, optics, household appliances, small and special electronics, electronics, clocks and watches, mobile phones and other industries for high-precision, multi-batch, complex shape of shaft parts and precision small parts.

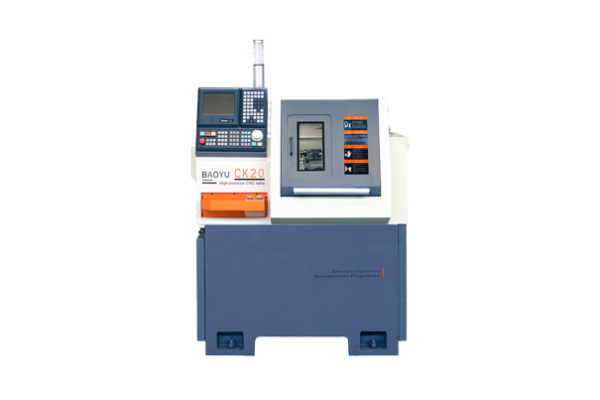

CK201-Y small precision gang CNC lathe

CK201-Y small precision CNC lathe is a full-protection practical and economical lathe developed according to the actual needs of the vast number of machining users. It has the characteristics of simplicity, practicality, convenient operation and high processing accuracy, and can realize the processing of complex parts such as straight lines, tapers, arcs, threads, etc. It is especially suitable for single and mass production products with complex parts, such as various instruments, meters, electronic products, micro-components, connectors, glasses, clocks, lighters and various hardware accessories, etc

CK 1107D Walking Center CNC Lathe

The three axes of CK1107D CNC lathe adopt linear rolling guide rail, which is driven by absolute servo motor. The linear tool arrangement structure has the characteristics of fast tool change and high precision. The CNC system has perfect functions and is easy to operate. Equipped with automatic feeder, it can realize automatic production.

Main products

Double-spindle CNC centering machine, small precision CNC lathe, CNC turning and milling compound machine tool, double-spindle CNC cutter arranging machine