Company Introduce

Guangdong Linkfair Hardware Equipment Technology Co., Ltd, founded in 2017, is a professional design, research and development, production and sales of Linkfair Group's intelligent equipment technology company, paid registered capital of 10 million yuan. The main business areas include: hardware industry digital production line, metal intelligent polishing and grinding equipment, factory digital software platform development (MES, SCADA, WMS, etc.), machine vision inspection equipment, factory intelligent logistics system. To provide customers with a complete digital factory solutions. The company has more than ten years of advanced technology base of automated production line manufacturing in the kitchenware industry, and has a group of highly educated technical talents with rich practical experience and courageous design and research and development. The existing staff of about 80 people, including more than 50% of R & D technicians, undergraduate education accounted for more than 45%, the average age of the team is 29 years old. The company's core technical team has more than 10 years of industry automation R & D and design experience, in the field of stainless steel table and kitchen utensils production of various key processes carried out a lot of research, and achieved a number of innovative inventions: the industry's first set of automatic deep-drawing system, the industry's first stainless steel pots and pans automatic production line, the industry's first automatic sanding production line and so on. The company adheres to the craftsmanship to create efficient, reliable and intelligent products, which have been highly recognized by customers, and has cooperated with famous enterprises such as SUPER, ANNOTHER, SANHE KITCHEN, HEBEI SANSHA, FENGALUMINIUM ALUMINUM, WINN'S AGRICULTURAL AND MOTHERDERS and so on. The company has a professional business and after-sales service team, can provide customers with a full range of high-quality pre-sale and after-sale protection services.

Exhibit brands

Exhibits

Binocular Intelligent Camera And Palletizing System

Low cost binocular intelligent camera, with palletizing software can quickly output palletizing, depalletizing required multi-layer points, combined with robot control to complete the automatic depalletizing production line; The detection algorithm of deep learning is embedded in the positioning of unpalletized objects, and different models can be quickly deployed for different products, so that the production line can be quickly put to use.

.png)

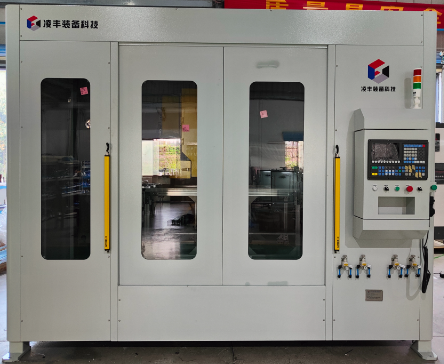

Vertical Sander

This machine is suitable for rough and fine sanding process of inner and outer surfaces of round pots and pans. It adopts the design of double knives, one machine can complete two different processes, compact structure, high practicality. At the same time, it contains 4 sanding belt discs, which can be arranged with different thickness of sanding belts, and it can hold 100 meters of sanding belts, and the sanding belts only need to be replaced once a day, so as to improve the production efficiency. This machine also has pressure control and forward and reverse collision protection function, with broken sanding belt alarm function and so on.

.png)

Double heads external polished machine

This machine is used for rough, fine polishing and fine polishing of the outer surface of round stainless steel products, it adopts double grinding head design, completing two procedures of polishing at a time, reducing processing time by half; equipped with a special control box, with detailed alarm function and troubleshooting information, supporting TCP/IP communication, automatic recording of production data, reserving space for informatization upgrading. It can also be equipped with various robots to form an automatic polishing production line.

Stainless Steel Tank Grinding Workstation

This machine is used for sanding and drawing at the plane of stainless steel groove body, it can be adapted to the sanding and drawing of single groove and double groove flange plane by replacing the groove body positioning tooling, and the left and right models of single and double grooves share one machine. This machine adopts integrated design, with double belt and drawing three process sanding; adjustable pressure; automatic compensation; workpiece in place to check; formula function; dust removal function and so on.

Stainless steel products automatic molding production line

This production line is used for deep drawing and forming of stainless steel products, through the application of advanced automatic loading system, double tensile detection system, positioning system, industrial robots and high-performance production equipment to form an automated production line, to realize the automation of round steel sheet drawing and forming, and the whole line program to support the adaptive one-key start function

Stainless steel products polishing production line

This production line is used for polishing the internal and external surfaces of round stainless steel pots, aluminum pots, pressure cookers, etc. The equipment on the line includes double-head polishing machines, disc polishing machines, internal polishing machines, automatic waxing manipulators, positioning devices, turning devices and other special models, which can be freely combined according to the quality of the product or the requirements of the process, which is flexible and has a high degree of flexibility.

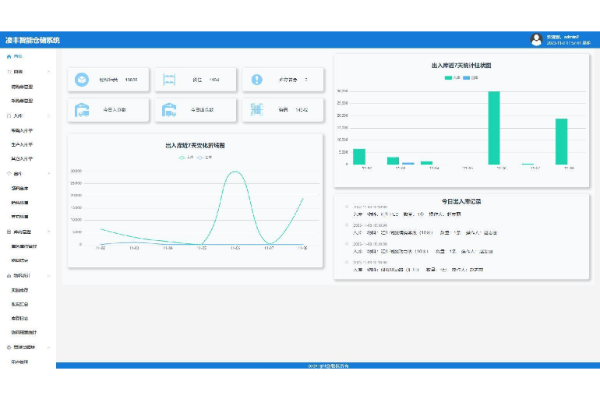

Digital Informatization Management System

Digital Management Kanban, the information control system for agriculture: records daily production data and monitors production trends over time. Through the digital management signage, the production value corresponding to various egg sizes can be visually analyzed, assisting the factory in timely adjusting feed formulas or cultivation methods to control the quality of product size.

WMS Intelligent Warehouse System

WMS Intelligent Warehouse System, using barcode, QR code, bright light system for accurate tracking and management of materials and commodities in the warehouse, including real-time monitoring and updating of information such as inventory quantity, location and status.

Main products

Hardware industry digital production line, Metal intelligent polishing and grinding equipment, Factory digitalization software platform development (MES, SCADA, WMS, etc.), Machine vision inspection equipment, Intelligent factory logistics system, etc.