Company Introduce

As a market leader in the automation industry, Maider strives to provide its customers with advanced solutions for intelligent manufacturing. Maider offers three categories of systems: Intelligent equipment, IO4-enabled data management and software, and Process development. Maider has obtained national innovation awards in China for its independently developed intelligent production assembly systems for the assembly and production of infusion apparatus, medical IV catheters, tubular spinning lines, and hemodialyzer devices. Since its start, Maider has delivered and installed more than 3000 automated solutions for hundreds of customers around the world, including local and international medical companies. We are focused and committed to the pursuit of excellence and will bring technological innovation, intelligent automation, and professional services to our customers.

Exhibit brands

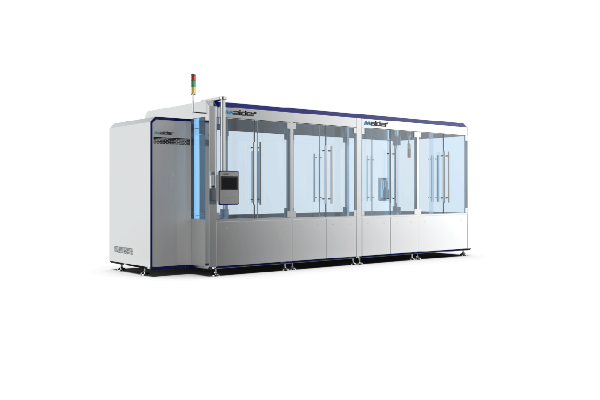

Main products

As a market leader in the automation industry, Maider strives to provide its customers with advanced solutions for intelligent manufacturing. Maider offers three categories of systems: Intelligent equipment, IO4-enabled data management and software, and Process development. Maider has obtained national innovation awards in China for its independently developed intelligent production assembly systems for the assembly and production of infusion apparatus, medical IV catheters, tubular spinning lines, and hemodialyzer devices. Since its start, Maider has delivered and installed more than 3000 automated solutions for hundreds of customers around the world, including local and international medical companies. We are focused and committed to the pursuit of excellence and will bring technological innovation, intelligent automation, and professional services to our customers.