Company Introduce

GUANGDONG NACRE HYDRAULIC CO., LTD. was established in Foshan, Guangdong in 1998, and moved to Zhaoqing National High-tech Development Zone, Guangdong in 2016, covering an area of 25000 square meters. After years of development, so far has more than 300 employees, including 70 intermediate engineers, senior engineers and technicians, and more than 200 sets production. NACRE Hydraulic engaged in R & D and manufacturing hydraulic cylinder more than 20 years, now we have vast experience and advanced professional production equipment to design and manufacturing hydraulic cylinder and system, we can design and manufacturing high corrosion resistance, low temperature resistance and high temperature resistance cylinder. The Max. cylinder diameter is φ1500 mm, the Max. single-stage stroke is 12 meters, and the max. working pressure is 150 MPa. In June 2019, NACRE Hydraulic passed the DNV ISO9001:2015 quality management system certification. Whether in construction machinery, environmental sanitation, mining, construction, port, automobile, wind energy, or in military industry, petroleum, metallurgy, aviation and marine, NACRE could design base on customers actual use and installation requirements according to international standards, and providecomplete sets of solutions and diversified comprehensive services. High quality and perfect and timely after-sales service is our goal. Continuous innovation and unremitting pursuit of better quality are our philosophy.

Exhibit brands

Exhibits

Injection molding machine cylinder (vertical)

The hydraulic cylinder of vertical injection molding machine is usually installed vertically in structure. This vertical structural design makes it well adapted to the overall layout of the vertical injection molding machine. Its cylinder body is generally made of relatively strong metal materials, such as high-strength alloy steel, which can withstand higher pressure. Because of its vertical installation, the lateral force is relatively small when pushing the mold up and down. This makes the mold in the process of movement to maintain a good degree of verticality to ensure the quality of injection molding products.

Hydraulic cylinder of injection molding machine (horizontal)

The hydraulic cylinder of horizontal injection molding machine is usually placed horizontally. Its cylinder body is cylindrical, and its material is mostly high-strength metal. It can produce large pushing force and pulling force, and is used for opening and closing the mold. It can control the movement speed according to the flow of hydraulic oil, realize different action requirements such as fast mold moving and slow mold closing, and has high action accuracy. It has good stability when working, and can adapt to the force transmission in the horizontal direction when installed on a horizontal injection molding machine. And it can adapt to the working requirements of injection molding machines with different sizes and different tonnages, and it is the key power component of horizontal injection molding machine.

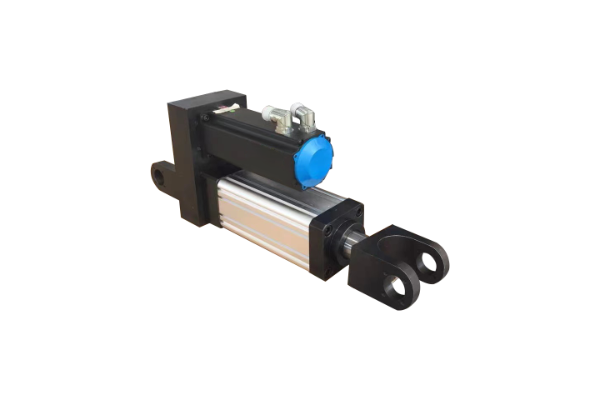

Electric cylinder

Through the precise motor control algorithm, the displacement of the piston can be precisely controlled to achieve precise linear motion, which is very critical in some automation equipment with high requirements for position accuracy. The electric cylinder is driven by the motor, and the speed and torque of the motor can be output stably, so as to provide stable power for the movement of the piston and make the process of pushing the load more stable. Compared with the traditional hydraulic cylinder, there are no problems such as hydraulic oil leakage and pressure loss, and the energy utilization efficiency is relatively good, especially in some low-load, frequent start-stop application scenarios. The electric cylinder has a fast response speed and can be started and stopped quickly.

Hydraulic Valve

Hydraulic valves are mainly used to control the oil flow direction, pressure and flow in the hydraulic system. By switching the oil channel, the movement direction of the actuator (such as oil cylinder and hydraulic motor) can be changed; the pressure can be adjusted to protect the system; the flow can be controlled to adjust the movement speed of the actuator.

Cylinder of die casting machine

Die-casting machine cylinder is the key power component of die-casting machine, its main function is to convert the hydraulic energy into mechanical energy to drive the die-casting machine to complete a series of actions such as mold closing, mold opening, injection, ejection and so on, so that the molten metal is formed into the required die-casting in the mold. It has a large thrust to meet the force required for mold closing and injection in the die-casting process, and can work stably in a high-pressure environment. Its motion precision is high, and it can accurately control the action of each part of the die-casting machine, including speed and displacement, to ensure the quality of die-casting products. And can adapt to the requirements of rapid and frequent actions of a die-casting machine and realize high-efficiency die-casting.

Main products

Hydraulic Cylinder / Hydraulic System / Hydraulic Stone Splitting Machine / Hydraulic Riveting Equipment / Hydraulic Valves