Company Introduce

Guangdong Pudian Automation Technology Co., Ltd. was founded in 2006. After nearly 10 years of development, it has trained a group of experienced and innovative senior welding equipment design and manufacturing engineers, a group of pre-sale, in sale and after-sale technical service personnel with excellent professional quality, and built a large-scale research and development center in the industry

Exhibit brands

Exhibits

Intermediate Frequency Inverter DC Spot Welding Machine

Features: balanced three-phase input, small impact of DC output on the user's power grid, energy saving, stable current, high welding quality Application: It is applicable to the welding of metal materials such as aluminum, copper, galvanized sheet, carbon steel, nickel, tungsten, high temperature enameled wire soft connection, inductance coil, etc.; It is widely used in the industries such as automobile and automobile parts manufacturing, new energy power battery, photoelectric communication, electric light source, motor, compressor, metal sheet, furniture, kitchenware, etc.

Capacitive Energy Storage Spot (Projection) Welding Machine

Features: firmer welding, good surface quality, such as: no blackening after welding, no color change and small deformation, save the follow-up process, save labor, save energy and reduce consumption. Application: mainly applicable to the welding of nuts, bolts, stainless steel, carbon steel and other metal materials with good conductivity; widely used in aerospace, military industry, automobile manufacturing, new energy, energy storage, hardware appliances, communications, electrical and other manufacturing industries.

Hand-Held Automatic Wire Feeding Fiber Laser Welding Machine

Features: fast welding speed, beautiful welding seam, small deformation, wide processing range, simple and flexible operation, high efficiency, high precision and high performance welding. Application: Suitable for welding of stainless steel plate, aluminum alloy plate, carbon steel, galvanized sheet and other metal materials; widely used in cabinets, kitchens, stairs, elevators, racks, ovens, stainless steel doors and windows guardrails, distribution boxes, stainless steel home and other industries.

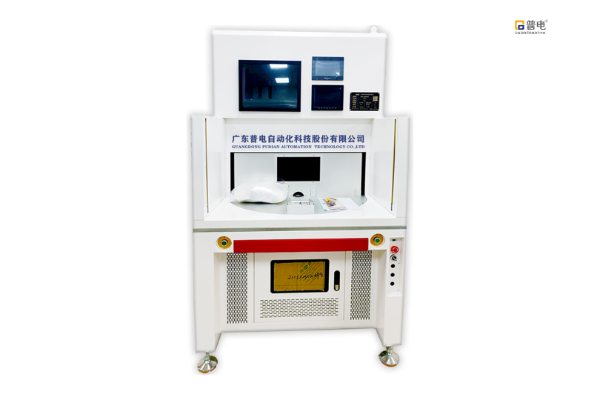

Desktop Intermediate-Frequency Inverter DC Spot Welding Machine

Features: Desktop structure design, space-saving, small current, more precise control. Compared with power frequency precision spot welding machine, it can weld a wider range of materials and has higher cost performance. Application: Suitable for welding of electric switch, purple steel wire connector, terminal wire, silver contact, SMD inductor, coil, fuse, hardware and other fine workpieces; Widely used for welding of electronic, electrical appliances, medical equipment, instruments and other precision components.

Platform Style Seamless Laser Welding Machine

Features: It is suitable for spot welding and full welding of various metal frame structure parts, sheet metal parts and other complex special-shaped internal angles, external angles, seams, etc. It has the advantages of simple operation, beautiful welding spots, fast welding speed, etc. Applications: Widely used in mobile phones, computers, lugs, microelectronic components, precision parts, intelligent terminal products, components, medical equipment and other industries, and various metal materials: carbon steel, stainless steel, copper, aluminum, galvanized and other materials, such as laser welding

Inductive terminal high-frequency micro arc welding machine

Features: Customized for soldering inductive transformer terminals. The arc formed by welding is stable, the appearance of the welding seam is smooth and flat, the welding strength is high, and the welding defects such as insufficient welding and missing welding are not easy to occur. Application: It is widely used in the terminal welding of inductance components in various electronic equipment, such as power adapters, chargers, electronic transformers, etc. It is also used in the terminal welding of inductance components in electronic control systems, sensors and other equipment in the field of automotive electronics.

Main products

The products include: medium frequency inverter DC spot (convex) welding machine, frequency conversion inverse AC / DC spot (convex) welding machine, platform medium frequency inverter traceless spot welding machine, vertical AC spot (convex) welding machine, desktop AC precision spot welding machine, desktop medium frequency inverter precision DC spot welding machine, argon arc welding machine, gas protection welding machine, mobile hanging spot welding machine, capacitive energy storage spot (convex) welding machine, handheld spot welding machine, resistance butt welding machine, AC / DC seam welding machine Capacitive energy storage stud welding machine, automatic straight / circumferential seam welding