Company Introduce

Shenzhen Monochrome Technology Co., Ltd. is headquartered in Guangming District, Shenzhen, with a subsidiary in Suzhou and related offices in North China and Northwest China. The company is committed to femtosecond laser micromachining technology research and application, including equipment development, production, sales and OEM business. The company's products are widely used in biomedical, aerospace, semiconductor advanced packaging, consumer electronics, research institutes and many other industries. The company's main products: femtosecond laser multi-axis precision hole-making equipment, femtosecond laser multi-axis precision etching/cutting equipment, semiconductor advanced packaging laser printing equipment, laser precision depaneling equipment, laser precision metal soldering/tin soldering/plastic soldering and other equipment.

Exhibit brands

Exhibits

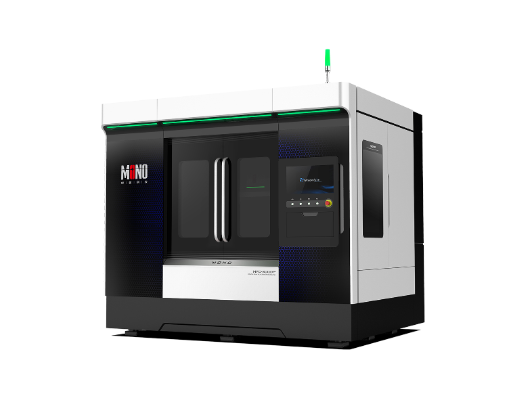

Femtosecond laser nano hole-making equipment

The invention relates to a special device mainly aiming at the requirement of optical waveguide laser direct writing, Equipped with high-quality laser micro-nano processing system, using high-quality high power The focuse lens tightly focuse that femtosecond laser to obtain a nanoscale focus Light spot, can realize nanometer precision fine processing, suitable for laser straight Optical waveguide processing, micro-nano processing of various thin film materials, etc. Use demand.

Five-axis femtosecond special-shaped micropore for equipment

It is equipped with high-degree-of-freedom beam scanning system, with five-dimensional beam scanning control capability, precise control of beam tilt angle, and high-precision, high-speed beam scanning control function. Equipped with mature programming software, it can realize the programming and processing of high degree of freedom graphics, including circular, inverted conical, rectangular, inverted pyramidal and other special-shaped holes. It is mainly used for the processing of high-precision special-shaped micro-holes in key parts of aero-engine turbine blades, air film holes, automotive nozzles and other industries.

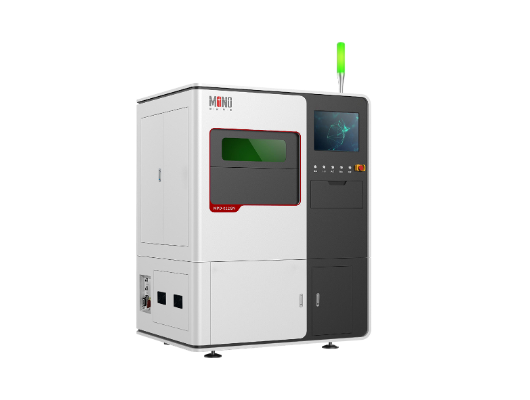

Femtosecond laser precision cutting equipment

It is a special equipment developed mainly for the fine processing requirements (no recast layer, no micro-crack, no carbonization) of all kinds of sheet materials with micron precision, which is dedicated to the fine cutting of all kinds of metals and non-metals with micron precision. It is suitable for fine precision non-destructive processing of ultra-thin metal copper foil, aluminum foil, stainless steel foil, nickel alloy foil and other materials, as well as precision laser scribing, grooving, etching and other precision processing of flexible PI, PET and silicon wafer substrates.

Femtosecond laser precision etching equipment

It mainly aims at the ultra-fine cold processing of curved surface and complex surface parts. It is suitable for micro-structure processing on the surface of metal, non-metal, especially composite materials, and can also be used for ultra-fine linewidth laser etching, scribing and grooving of glass, silicon wafer, zirconia ceramics and other materials.

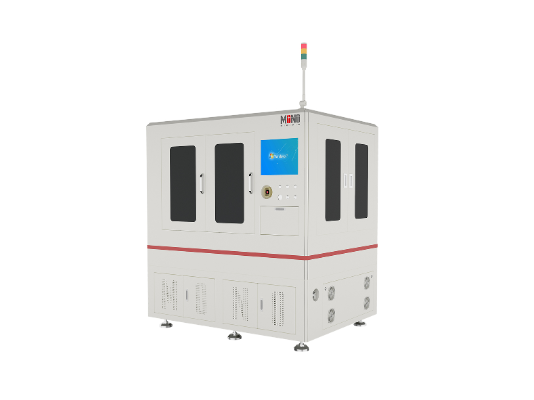

Femtosecond laser precision tube cutting equipment

Femtosecond laser precious metal precision tube cutting equipment, using imported lasers, is a special equipment for precious metal precision tube cutting developed mainly for various extreme processing requirements (no recast layer, no micro-cracks, no carbonization), which is mainly used for fine precision non-destructive processing of thin metal, aluminum foil, stainless steel foil, nickel alloy foil and other materials, and for implantable and interventional cutting of various metals and non-metals.

Main products

femtosecond laser multi-axis precision hole-making equipment, femtosecond laser multi-axis precision etching/cutting equipment, semiconductor advanced packaging laser printing equipment, laser precision depaneling equipment, laser precision metal soldering/tin soldering/plastic soldering and other equipment.