.png)

Company Introduce

Shenzhen ZEGE Robot System Co., Ltd. is a subsidiary of Shenzhen Hongli Science and Technology Industry Co., Ltd., a state-level "specialized, special and new" small giant enterprise, which was established in July 2017 with a registered capital of 10 million yuan. Our company is a high-tech enterprise specializing in R & D and production of visual arc welding robots, automatic flexible feeding, robot drivers and high-precision servo electric cylinder equipment. Since its establishment, the company has won awards such as Baoan Industrial Robot Backbone Enterprise, Shenzhen Top Ten Technological Innovation Industrial Robot Enterprises, Shenzhen Industrial Robot Technology Innovation Award, Shenzhen Top Ten Key Parts Enterprises and Small and Medium-sized Technological Enterprises; It has obtained 2 scientific and technological achievements, 21 domestic invention patents, 3 international inventions, 38 software patents, 71 utility model patents and 13 appearance patents. It has built an independent machining center and production base, and has a large number of experienced technicians in mechanism design, software development, equipment assembly and commissioning. To carry forward the spirit of innovation and focus on technology research and development, we firmly believe that by giving full play to the advantages of our own comprehensive strength and cooperating with partners and users in depth, we will contribute to the revitalization of the country's intelligent equipment industry and help China leap from a manufacturing power to a manufacturing power.

Exhibit brands

Exhibits

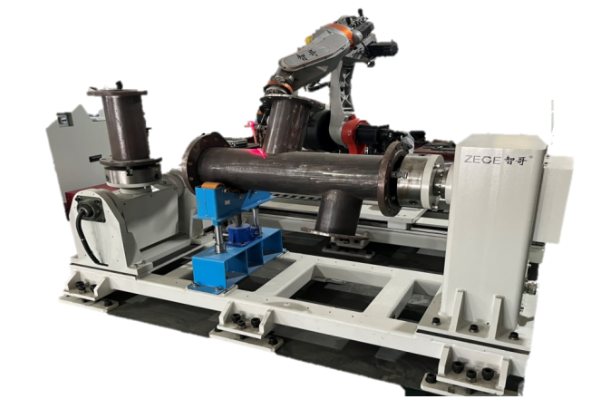

Intersecting line pipe welding system

The product is equipped with robot line laser vision system, which can identify the size, weld seam and pipeline structure through line laser vision, such as flange welding of different sizes, intersection of different or the same pipeline, intersection of different oblique angles, pipeline butt joint, etc., and accurately feed back the position and welding attitude data of the weld trajectory, and guide the robot to adopt the corresponding welding process. The purpose of flexible pipeline welding production is achieved.

Flexible feeding workstation

The core components of flexible feeding equipment are SCARA robot, visual recognition and detection system, flexible vibration plate and automatic feeding bin, which can easily realize full automation. The flexible feeding workstation is a standardized and modular integrated feeding equipment, which can complete a series of operations such as feeding, arrangement, identification, positioning, picking and sorting of various irregular parts. The flexible feeding workstation can reduce a lot of labor costs and management costs, operate continuously for 24 hours, and maintain consistent production quality and efficiency.

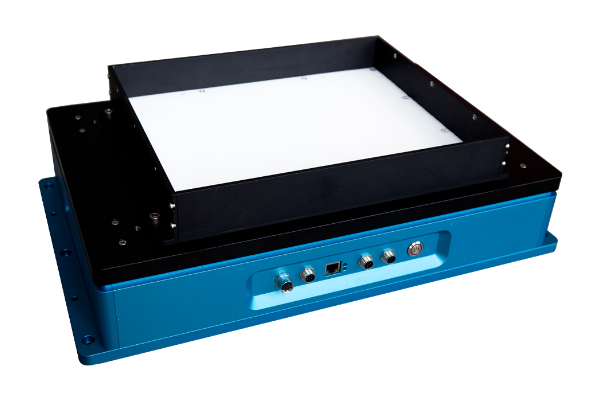

Flexible vibrating disc

The flexible vibration plate of Zhige robot is easy to operate, and has superior product compatibility, stability and repeatability; it has wide versatility, and is suitable for 99% of small parts in industrial automation production, including special-shaped parts and fine vulnerable parts; it has up to 11 motion modes, covering all the vibration needs of visual feeding applications. Fast switching of production varieties does not require the replacement of hardware structure, and the program switches production varieties with one key to meet the current flexible production needs of intelligent manufacturing in small batches and multiple varieties.

Servo electric actuator

The product adopts precision planetary roller screw drive technology and built-in brushless servo motor. It is suitable for motion control systems with low, medium and high performance requirements. The product integrates the built-in brushless servo motor with the roller screw drive structure. The rotating motion of the servo motor is directly transformed into the linear motion of the push rod through the roller screw mechanism. The product can be customized according to the needs of customers.

CNC STUD WELDING SYSTEM

The CNC stud welding system (automatic stud welding platform) is a high-precision, high-efficiency fully automatic CNC stud welding device. The X- and Y-axis drives use high-precision ball screw linear modules, which provide stable operation, high positioning accuracy, and long service life. The control system uses industrial-grade PC or PLC or drive-control integration, which can be equipped with energy storage stud welding machines or arc-pulling stud welding machines to meet different welding requirements. The Z-axis can be selected from pneumatic or electric servo drives, and can be equipped with one or more welding terminals to meet personalized needs in different fields.

Small four-axis flexible workstation

The core components of flexible feeding equipment are SCARA robot, visual recognition and detection system, flexible vibration plate and automatic feeding bin, which can easily realize full automation. The flexible feeding workstation is a standardized and modular integrated feeding equipment, which can complete a series of operations such as feeding, arrangement, identification, positioning, picking and sorting of various irregular parts. The flexible feeding workstation can reduce a lot of labor costs and management costs, operate continuously for 24 hours, and maintain consistent production quality and efficiency.

Small six-axis flexible workstation

Small six-axis flexible feeding workstation is a high-precision and high-efficiency automatic feeding solution designed for modern intelligent manufacturing scenarios. The workstation uses six-axis manipulator as the core, combined with advanced visual recognition system and intelligent algorithm, can quickly adapt to a variety of workpiece types and complex feeding needs, greatly improving the flexibility and efficiency of the production line.

Parallel manipulator flexible workstation

Parallel manipulator flexible workstation is an efficient and high-precision automation solution based on parallel mechanism design, which is specially designed for modern intelligent manufacturing scenarios. The workstation adopts advanced parallel manipulator technology, combined with intelligent control system and visual recognition function, which can quickly complete high-precision grasping, sorting, assembly and other tasks, and is suitable for flexible production needs of multi-varieties and small batches.

Tube-sheet welding workstation

This product is an intelligent welding workstation specially designed for corrugated plate workpieces by Shenzhen Zhige Robot System Co., Ltd., which adopts binocular visual trajectory tracking The real-time tracking technology and the tracking operation software control system realize the parallel processing of real-time visual recognition and real-time operation of the robot, and the whole process of welding seam visualization and real-time tracking can be greatly improved. And that operation efficiency and the weld quality of the robot are greatly improved.

Main products

Robot and automation equipment, a complete set of automation solutions, automatic flexible feeding, flexible vibration plate, flexible feeding workstation, visual arc welding robot, hollow electric cylinder, stud welding platform, robot driver, high-precision servo electric cylinder equipment R & D and production of high-tech enterprises. In addition, it also undertakes various automatic welding platforms and robotic workstations such as spot welding, stud welding and arc welding.