Company Introduce

The world's first patented invention models: 1 pair of row type four ox head spark machine, 2 2 type lifting spark machine Specializing in the development of precision CNC electric machine tools and precision control technology, in the past 30 years, relying on strong scientific research/talent advantages, while "introducing/digesting/absorbing" international advanced technology, we have continuously pursued the spirit of excellence and innovation, and continuously industrialized BM450, ST750, ST1000, ST1800, (four cows) products. Its key parts are all international famous brand products, and the CNC system and processing technology have the characteristics of intelligence, automation, flexibility and software, so as to realize the high precision, high efficiency and high surface finish of machine tool processing, which is a cost-effective product: With Sino-Japanese joint venture research and development, we fully grasp the core technology of high-speed milling and high-quality product service process, we provide customers with systematic automotive die finishing solutions. Facing domestic and foreign competitors, after more than ten years of development, the product quality and core technology have been continuously improved, the product specifications are complete, and the process service is perfect. At present, it has become the only equipment manufacturer of advanced precision EDM machine tools in China, and is the leader of the domestic precision large-scale EDM machine tool equipment industry.

Exhibit brands

Exhibits

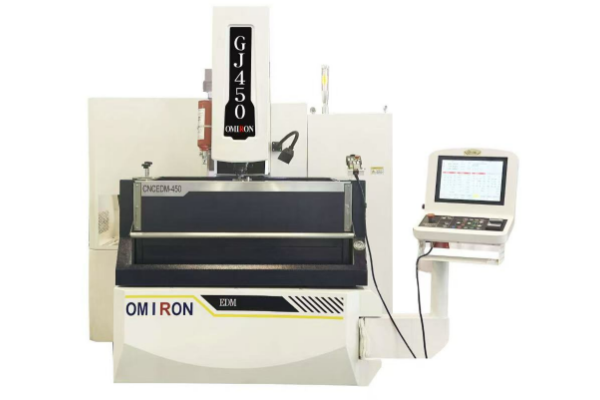

Spark machine equipment

Durable accuracy: single stroke is adopted for the Z axis of the machine tool to avoid the error caused by the second stroke. Durable stability: Z-axis of the machine tool adopts imported servo motor and imported screw rod High Quality Spark Expert Controller Discharge System: Evaluates the discharge of sparks to play a special role when necessary. Fast speed: the finishing time is 2-3 times faster than ordinary spark machine Simple system interface, excellent operability, simple and convenient The training time of the operator is reduced, the operator adds his own experience to the NC at any time, and the machine tool is allowed to create its own machining parameter table, which can be saved and used in the new program. Casting: strong rigidity, not easy to deform. Ball guide: Linear contact has smaller friction coefficient than ball guide, strong rigidity, long service life, no wear, high precision, easier maintenance, and high precision in three-axis processing The new system has 30% higher machining efficiency, 30% lower electrode wear rate, more uniform finish and no secondary discharge.

Spark machine equipment

Durable accuracy: single stroke is adopted for the Z axis of the machine tool to avoid the error caused by the second stroke. Durable stability: Z-axis of the machine tool adopts imported servo motor and imported screw rod High Quality Spark Expert Controller Discharge System: Evaluates the discharge of sparks to play a special role when necessary. Fast speed: the finishing time is 2-3 times faster than ordinary spark machine Simple system interface, excellent operability, simple and convenient The training time of the operator is reduced, the operator adds his own experience to the NC at any time, and the machine tool is allowed to create its own machining parameter table, which can be saved and used in the new program. Casting: strong rigidity, not easy to deform. Ball guide: Linear contact has smaller friction coefficient than ball guide, strong rigidity, long service life, no wear, high precision, easier maintenance, and high precision in three-axis processing The new system has 30% higher machining efficiency, 30% lower electrode wear rate, more uniform finish and no secondary discharge.

Spark machine equipment

Durable accuracy: single stroke is adopted for the Z axis of the machine tool to avoid the error caused by the second stroke. Durable stability: Z-axis of the machine tool adopts imported servo motor and imported screw rod High Quality Spark Expert Controller Discharge System: Evaluates the discharge of sparks to play a special role when necessary. Fast speed: the finishing time is 2-3 times faster than ordinary spark machine Simple system interface, excellent operability, simple and convenient The training time of the operator is reduced, the operator adds his own experience to the NC at any time, and the machine tool is allowed to create its own machining parameter table, which can be saved and used in the new program. Casting: strong rigidity, not easy to deform. Ball guide: Linear contact has smaller friction coefficient than ball guide, strong rigidity, long service life, no wear, high precision, easier maintenance, and high precision in three-axis processing The new system has 30% higher machining efficiency, 30% lower electrode wear rate, more uniform finish and no secondary discharge.

Main products

Precision CNC machining, mold processing