Company Introduce

Established in 2012, Dongguan Guda Machinery Manufacturing Co., Ltd. is a professional manufacturer of high-end CNC machine tools, a national "Little Giant" enterprise, a national high-tech enterprise, a top 100 innovative enterprise in Dongguan, a listed reserve enterprise in Dongguan, and a multiplier enterprise in Dongguan. Main products: CNC bilateral milling machine, CNC gantry milling machine, CNC gantry grinder, CNC machining center and other high-end intelligent equipment. Professional for the mold industry to provide efficient processing solutions. Among them, CNC bilateral milling machine is the flagship product, and the core components and systems are self-developed by Guda, breaking through technical barriers and realizing domestic substitution. It has more than 100 patented technologies and software copyrights, and has passed ISO9001: 2015 quality management system, EU CE, Korea KCS certification, etc.

Exhibit brands

Exhibits

CNC Double Side Milling Machine TH-450NC

According to the high quality machining requirements of polyhedral metal components, the end face structure can be machined in one process and the appearance can reach mirror quality by using the high light end face machining method of milling instead of grinding. The machine is equipped with a secondary developed numerical control system, equipped with double milling heads and a rotary worktable, which can automatically position, measure and rotate to complete the processing of four sides of the hexahedron only by inputting the processing data, and can independently analyze the cutting depth of each tool according to the cutting allowance and complete the rough milling and finish milling actions according to the pre-input program. Workpieces are processed according to the processing parameters of different materials, and all processes such as positioning, clamping, measuring, four-side processing, chamfering and the like are completed after one-key starting.

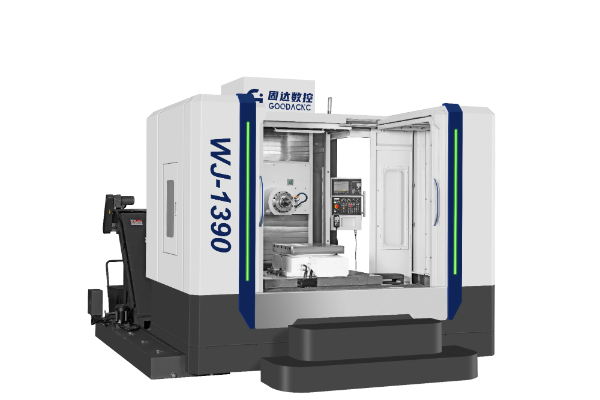

Horizontal machining center WJ-1390

The machine tool is equipped with a super-large inverted "T" type bed base, Y-axis integral double-layer wall moving column type, positive hanging headstock type casting structure, heavy duty heavy cutting, roughing and finishing tools, durable; In order to strengthen the function of roughing, the customized thickened spindle is equipped with a 30 KW high-torque motor, which is suitable for roughing and finishing of precision molds, engineering machinery, automotive power, locomotives, ships, marine engineering and other industries.

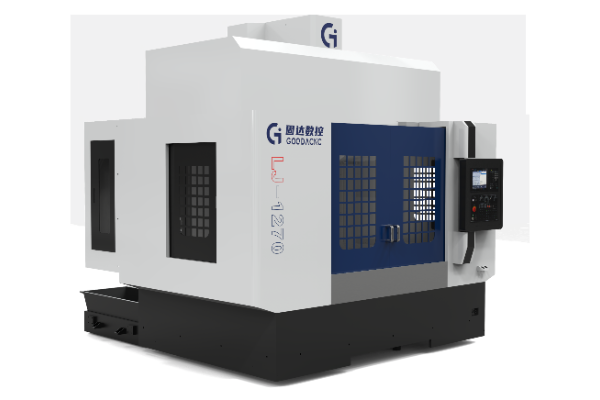

Double tool magazine LJ-1270

LJ-1270B-2T vertical machining center with double tool magazines is a C-type vertical machining center designed by absorbing advanced technology at home and abroad. The main structure of the machine tool is composed of five castings: the bed, the slide, the worktable, the column and the headstock. The whole machine has high rigidity, good stability and high dynamic and static characteristics. The lathe bed is supported by a large span, and the best anti-deformation structure of the casting is obtained according to the Bessel point physical anti-deformation principle. The fuselage is designed by finite element analysis to ensure the stability and rigidity of the mechanism. The X/Y axis of the machine tool adopts high-precision heavy-duty roller linear guide rail, and the Z axis adopts rectangular hard rail structure, so the machine tool has good rigidity, small vibration and high precision during feeding. The machine tool adopts a shoulder-resistant tool magazine structure. The left and right shoulders of the column are equipped with two 32T disc-type manipulator tool magazines. The tool magazine support structure is reasonable and stable. The machine adopts high-performance CNC system, which can realize any three-axis linkage processing. It has the functions of drilling, boring, milling, expanding, reaming, tapping, linear interpolation, circular interpolation, spiral interpolation, three coordinate linkage and so on. The product has wide application range and strong processing ability, and is suitable for heavy cutting processing. Widely used in mold, new energy, automotive, aerospace, electrical, instrumentation, textile, printing and other industries.

Main products

Main products of Dongguan Guda Machinery Manufacturing Co., Ltd.: CNC bilateral milling machine, CNC gantry milling machine, CNC gantry grinder, CNC machining center and other high-end intelligent equipment. Professional for the mold industry to provide efficient processing solutions. Among them, CNC bilateral milling machine is the flagship product, and the core components and systems are self-developed by Guda, breaking through technical barriers and realizing domestic substitution.