Company Introduce

Dongguan YuZuan CNC Technology Co., Ltd., located in where known as the "Manufacturing Capital of the World", Houjie, Dongguan, is a company manufacturing carbide coated petroleum pipe thread inserts, milling inserts, turning inserts, OEM and non-standard custom tools, integrating R&D, production, sales and service. YuZuan CNC company has advanced and reliable production lines of various cutting tools, which can provide cutting tools with high quality, high precision, high efficiency and excellent cutting performance. The product is commonly used on the cutter heads and tool holders of similar foreign products, its precision and cutting performance have reached the international level of similar products. As so far, YuZuan cutting tools have been widely used in CNC lathes, CNC machining centers, mold blanks, mold bases, molds, precision hardware, machinery manufacturing, metal casting processing, geological mining, woodworking machinery and other industries. Technology leads development, service creates value! Since establishment, YuZuan CNC company through arduous entrepreneurship and continuous innovation as its development policy. It has won a good reputation and customer favor with high-quality products and considerate services. Its business covers various provinces in China and overseas, such as Europe, America, India, Vietnam, Thailand, Turkey, Egypt, South Korea, Malaysia, Pakistan, and Indonesia, etc. YuZuan CNC Company has always been adhering to the business philosophy of "Quality builds the brand, integrity creates the future”, and we strictly control products quality and stability, comply with reputation first, sincere service, mutual benefit, and fast supply, seeking win-win cooperation with the new and old customers. With excellent quality, pragmatic service and affordable prices, we have created well-known brands, such as "YuZuan", "Knife World", and "YIOUKE" etc., and have a good reputation among the cutting tools industry. Our value proposition: Serve every customer well, make every partner successful. Our Vision: To enhance value with quality, to be innovation-oriented, and to be the most trusted cutting tool brand in China.

Exhibit brands

Exhibits

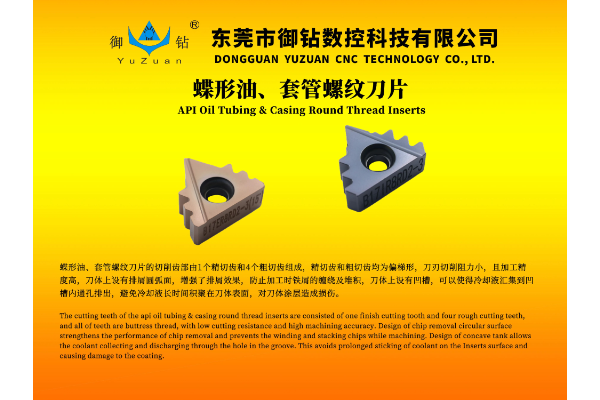

API Oil Tubing & Casing Round Thread Inserts

The cutting teeth of the api oil tubing & casing round thread inserts are consisted of one finish cutting tooth and four rough cutting teeth, and all of teeth are buttress thread, with low cutting resistance and high machining accuracy. Design of chip removal circular surface strengthens the performance of chip removal and prevents the winding and stacking chips while machining. Design of concave tank allows the coolant collecting and discharging through the hole in the groove. This avoids prolonged sticking of coolant on the Inserts surface and causing damage to the coating.

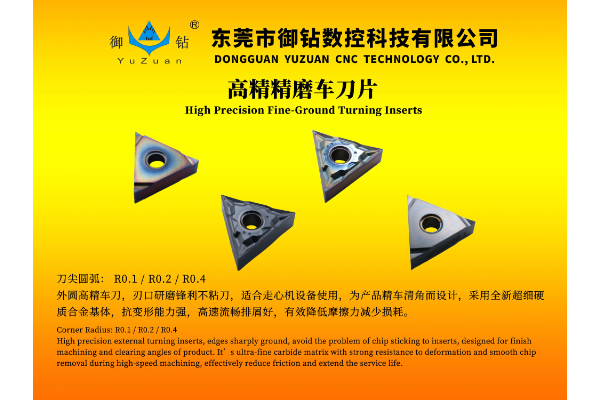

High Precision Fine-Ground Turning Inserts

High precision external turning inserts, edges sharply ground, avoid the problem of chip sticking to inserts, designed for finish machining and clearing angles of product. It' s ultra-fine carbide matrix with strong resistance to deformation and smooth chip removal during high-speed machining, effectively reduce friction and extend the service life.

SNMU High-Feed Milling Inserts

SNMU130708ZNER, with a main inclination angle of 88 degrees, can be applied to various processing operations to avoid contact with the fixture during processing. It is suitable not only for face milling but also for shoulder milling. The four-corner negative-shaped insert can be used as eight different angles for processing, offering excellent cost-effectiveness. With a special insert tip shape and chip breaker grooves, it achieves both reduced resistance and sharp cutting performance.

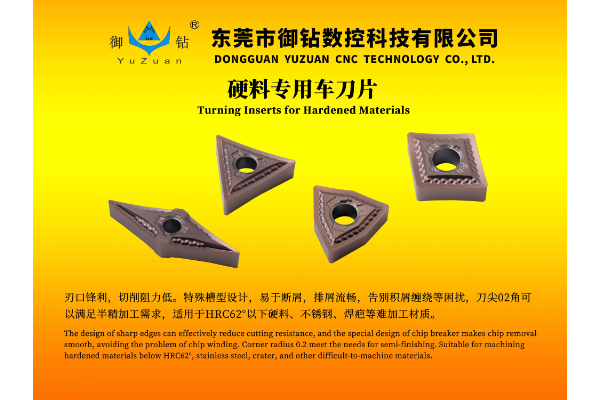

Turning Inserts for Hardened Materials

MSK series turning inserts, the design of passivated sharp cutting edges makes the insert more wear-resistant during cutting. With special chipbreaker, the insert can easily break chips and avoid the formation of built-up edges. Diversified corner radius meet different machining needs. Suitable for processing: steel below HRC62°, stainless steel, superalloys, titanium alloys.

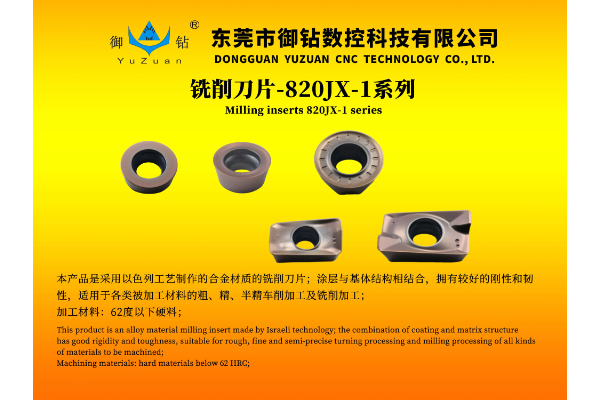

Milling Inserts - 820JX-1 Series

This product is an alloy material milling insert made by Israeli technology; the combination of coating and matrix structure has good rigidity and toughness, suitable for rough, fine and semi-precise turning processing and milling processing of all kinds of materials to be machined. Suitable for processing: steel below HRC62°

Main products

Carbide coated thread inserts for oil&gas industry, milling inserts, turning inserts, boring inserts, drilling inserts, and we provide OEM service and non-standard customization.