Company Introduce

NUOVA ELETTRONICA is based in Perugia, Italy. With more than 40 years of experience in the field of press brakes safety. The company's leading product is laser safety devices , Since the year of 1979, Products and technology are among the best in the world. NUOVA ELETTRONICA is in the forefront of the press brake safety devices. A design team with technical excellence and advanced ideas. Attaches great importance to industry safety laws and regulations all over the world while the technology is constantly innovating. The products occupy a large share in the domestic and overseas markets. The factory establishes standardized assembly lines, equipped with modern assembly lines, automated test systems, machining, and UV printing workshops. The processing of parts and components of all products is completed independently, subverting the traditional processing and outsourcing methods, ensuring the timeliness of delivery and the stability of product quality. NUOVA ELETTRONICA officially entered the Chinese market in 2016 and established a subsidiary in Shanghai, it is Nuoguard (Shanghai) Industrial Automation Co., Ltd.

Exhibit brands

Exhibits

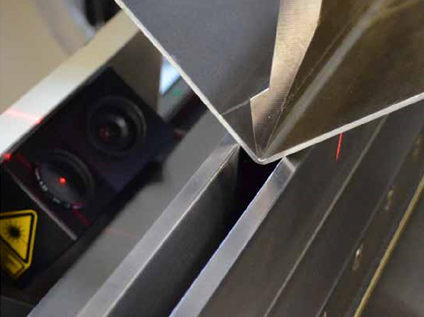

DSP

DSP LASER protects the pressbrake operator from the danger of crushing that can take place accidentally between the moving part of the machine and the fixed one.The project idea used for this device is the one to fit out the moving pert of the pressbrake with a protection zone. This is a volume of suitable and special dimensions generated by DSP LASER and placed under the upper tool vertex at a higher distance than that the machine requires to stop.So the protection zone, that moves together with the mobile part because integral with it, advances the race of this one towards the fixed pert. An obstacle (for example the Operator fingers) when entering the protection zone. Is detected immediately causing consequently the interruption of the mobile part motion.

Bending Follower

▪Suitable for large size sheet metal bending,reduce artificial ▪Improve machine tool processing efficiency,ensure the accuracy of bending Angle ▪Accurately read the displacement data of Y axis and keep 100% synchronization with Y axis ▪Independent control system, No need to upgrade the original system of the bending machine ▪Suitable for matching with various types of bending machines ▪Adjust the up and down movement according to the height of the die, and the size of the V port. ▪Equipped with a brush table to prevent any sheet from being scratched,slipped or dropped ▪Flexible and easy to use, easy to load and unload, Realize a multi-platform sharing mode with moving.

Bending Angle Measurement System

搂 LaserCheck does not only include angle sensors. It is a complete system to be connected to press brakes. It includes diff erent interfaces for press brake controllers, strain gauge sensors to detect spring-back and moto-rized systems for sensor movements.

Bending Line

B-Sniper 01 traces a high visibility laser beam on the piece to be bent to simulate the fold line. The operator only has to match the references drawn on the piece to the line projected by B -Sniper 01.

Main products

Safety devices,Bending follower,Bending Angle Measurement System,B-Sinper