Company Introduce

Established in 2021, Guangdong Lingchuang Intelligent Equipment Co., Ltd. is a national high-tech enterprise. Located in Shuibei Industrial Zone, Huizhou City, Guangdong Province, the Intelligent Manufacturing Innovation and Entrepreneurship Base of the Chinese Academy of Sciences (Huinan) consists of a Founded by a technical team engaged in the first-line research and development of non-standard automation industry for ten years, the company has mastered the core technology. Own hands for the development concept, with excellent technology and unconditional service, for customers to continue to create value. The current company has three core technologies: flexible vibration plate technology, machine vision technology and industrial robot Technology. The main products include flexible vibrating plate, flexible feeding module, flexible feeding workstation, flexible swing plate equipment, Flexible taping equipment, etc. With the help of AI vision software, core algorithm and intelligent deep learning advantages, it focuses on flexible and universal intelligence. Automation equipment, to solve the factory variety, small batch production change frequently, change time-consuming problems, we Independent research and development of integrated control technology, to achieve a key change, adhere to innovation, quality, service for the purpose of helping Intelligent manufacturing automation transformation and upgrading.

Exhibit brands

Exhibits

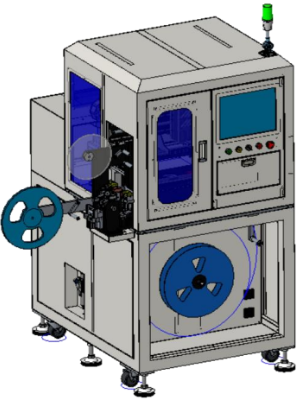

Fully automatic flexible taping machine

Based on a flexible vibration feeding system, a visual material selection and detection system and an upper computer system, the positive and negative directions of bulk materials are identified in sequence, and the bulk materials are placed in a carrier tape, so that the device is widely applied to chips, precision hardware, nickel sheets, micro capacitors and resistors, and braiding of shielding cases, and is universal and compatible with small batches and multiple varieties. Characteristic 1, flexible universal, to achieve 15 minutes of rapid switching product flexible feeding, greatly reducing the product scratch rate. 2, high pixel camera, from coarse positioning to fine positioning, standard tape detection camera. 3. Modular design of software and hardware, quick change of suction nozzle, support for heat sealing/cold sealing.

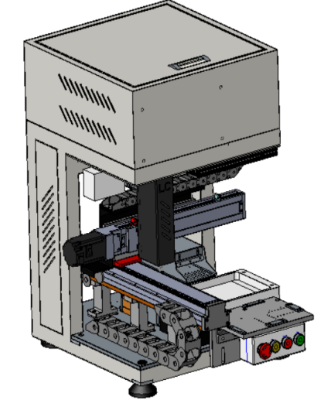

Table top type loading and placing machine

Air pressure: 0.5 ~ 0.7 Mpa Capacity: 2000-4000pcs/H Accuracy: + 0.1mm Applicable part size: < 50mm Meet the common use of small batch and multiple varieties. Small space, can be placed in equipment, workbench, etc. Any position. To meet the flexible production needs of fast switching.

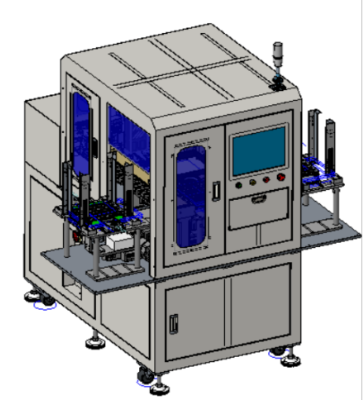

Changeover tray flexible feed and tray swaying machine

It can be used for automatic placement of similar products such as TPU accessories on various fingerprint modules, and can also be extended to Automatic layout of electronic products, mobile phone accessories, hardware, plastic plug-ins, PFC, etc. The product counting and data saving functions solve the problems of difficult arrangement of small-size parts and high labor cost. Flexible disk feeding, easy to distinguish the direction of the material. It has strong universality and can quickly realize the arrangement of different materials. CCD positioning material taking and detection, high precision, easy to distinguish the advantages of material. The tray can be switched automatically, and the tray can be replaced without stopping the machine.

Full-automatic flexible feeding plate swinging machine

Flexible disk feeding, easy to distinguish the direction of the material. It has strong universality and can quickly realize the arrangement of different materials. CCD positioning material taking and detection, high precision, easy to distinguish the advantages of material. Material tray buffer, fully automatic loading and unloading.

Main products

AI vision intelligent feeding equipment Flexible vibrating plate | Machine vision | Industrial robot Flexible feeding | Flexible wobble | Flexible braid | assembly test | non-standard automation equipment