Company Introduce

Founded in 1979, FFG has established three business groups based on the concept of honesty, responsibility and sustainable operation: (1) Machine Tool Business Group. (2) Industrial equipment business group. (3) Green energy business group. Among them, the machine tool business group is the main body, accounting for more than 60% of the group's revenue. In 1985, the Group's Machine Tools Division began to market its self-created FEELER brand at home and abroad. In the machine tool business group, there are 37 machine tool brands and 50 production bases, and they are distributed in the 13 largest machinery manufacturing countries and regions in the world, including China, Taiwan, the United States, Germany, Japan and Italy. It is one of the largest vertical machining center manufacturer groups in the world.

Exhibit brands

Exhibits

FFG VFX-820A

VFX-820a 1. A new model of efficiency and a magic weapon to create profits. Whether it is precision parts processing or general mold processing, Youjia's new generation of VFX/VMX series vertical machining center machine will provide you with impeccable excellent performance. VFX/VMX series is carefully developed. High-precision machine types are most suitable for the processing needs of the high-speed cutting parts market; 2. The body and castings are made of high and Mihana cast iron, which are stable and ensure long-term use without deformation. The main structure adopts ANSYS and NASTRAN finite element analysis software to achieve optimal analysis and design and ensure the best rigidity and stability; 3. High-speed straight spindle is in line with the market trend, which can show the high shaft rigidity with excellent characteristics; 4. XYZ axis is matched with the full line rail to achieve high acceleration/deceleration, the Z axis stroke is increased to 635 MM, and the bottom of the column is A-shaped special strengthening design; 5. The pedal trim is equipped to increase the texture and avoid sheet metal scratches; 6. The best performance of precision, rigidity and stability.

Liwei LTC-25IXXL

Performance, characteristics and specifications of machine tool 1. Solid and durable body structure The main frame of the engine adopts the design of 45 ° full inclined back. It is made of the best Mihanna cast iron engine body and careful rib support. The shock absorption force is ten times higher than that of the general cast iron material. After special research and development, the inner ribbed casting has extremely high torsion resistance and super shock resistance. All linear slide rails are pre-pressed and designed to prevent water and scrap iron. The wide internal space allows the operator to easily change the tools and jaws. With the high rigidity structure, it creates a machine with small space, high precision and high stability with multiple functions. 2. Spindle High precision and high rigidity. Whether it is turning or milling, it can make the surface of the workpiece very smooth and perfect. 3. Precision sleeve type main shaft The main shaft produced by Liwei keeps improving with the latest labyrinth waterproof design to ensure long service life. Spindle sleeve integrated structure, with bevel thrust bearing and roller bearing, can have the best accuracy and zero deflection operation. The design of heavy spindle head, high rigidity spindle and high quality bearing is conducive to heavy cutting, high speed and high precision processing. 4. Spindle head The spindle head adopts the symmetrical design of heat sink, with high rigidity and strong shock resistance: after a long time of turning, it will not produce thermal displacement to ensure high precision, so that the workpiece is more perfect. 5. Double nut pre-pressing screw High-quality ball screws of well-known brands are adopted, and their quality is beyond doubt. The main features are, due to the bilateral fixed pretension, the two ends of the ball screw are fixed and the central rotation torque is strictly tested, which will not produce torque deformation, and the use mission is long and the precision is high. 6. Wide working environment The design of wide working space provides the best turning environment and good chip removal effect. The sliding rails of the two shafts are protected by protective covers. The full-dense shape ensures the safety of the operator and the cleanliness of the working environment. The view windows of the anti-chip cover door are made of safety tempered glass. 7. Stable and reliable turret The new hydraulic turret design, solid cast iron body and large bonding area can greatly improve the rigidity, thereby improving the cutting efficiency, prolonging the tool life, improving the processing accuracy, and meeting the requirements of most processing. A servo turret (optional) is also available to reduce tool change time and cut time. 8. Tailstock The lathe tailstock is made of cast iron with high rigidity. The tailstock slide plate is directly fixed to the fixed frame track to provide sufficient support strength for the tailstock. The high-precision Mo-type push-pull center can provide unparalleled high rigidity. The tailstock is controlled by hydraulic pressure to realize automatic expansion and contraction of the sleeve. 9. New and convenient operation The film operation box with both aesthetics and ergonomics makes man-machine integration. Long life and high brightness working lamp, so that there is no dead angle in the processing area. 10. Convenient chip removal The inclined wound surface is designed with a large space, which is beneficial to the falling of processing chips, and can be matched with a chain-type chip removal machine to facilitate chip removal, so as to maintain a clean working environment, provide a simple, convenient, safe and labor-saving environment, and achieve the purpose of reliability. 11. Automatic processing equipment Automatic feeder (optional) and cartridge Chuck (optional) can be used together to achieve automatic processing equipment, which greatly improves the production efficiency and the demand for rapid processing, so that the utilization rate of the machine is higher. 12. Hard rail The contact surface between all hard rails and TURCITE-B is treated by precise shoveling, and the special oil groove design shows full bearing capacity in all directions, which makes the heavy cutting characteristics of the hard rail machine more solid.

Youjia U-800

High speed precision machining with excellent performance 1. Youjia five-axis machining center is specially designed for high-speed, high-precision machining and fine machining. Its body structure is a crown block design, with U-shaped base and main column, to enhance the structural stability to the highest level. The surface diameter of the cradle worktable is 800 mm, which can withstand heavy load. The 12000 rpm straight spindle can completely meet the user's expectations in Gaudi and high efficiency processing performance. 2. Crane structure Youjia U800-5ax adopts crane structure design and has spacious processing space. Makes it easier to load large workpieces. And is convenient for the operator to observe the current processing condition at any time. 3. U-shaped structure of base column Advanced U-shaped structure design can improve the structural rigidity and processing accuracy. * X, Y, Z axis rapid feed up to 48 meters 1 minute. Can accommodate a large diameter rotary work surface. 4. Three-axis overlapping and two-axis separation design Can avoid that distance between the program proces point and the intersection point of the two slip axes. It is easy to compensate the arc seat error of the rotating shaft and the three-axis movement error. O as to ensure the stability and accuracy of the machine alliance. 5. The three-axis moving area is separated from the processing area * The three-box moving area is separated from the processing area. In addition to having a more convenient shoulder removal feature, it also contributes to the machine's chip resistance.

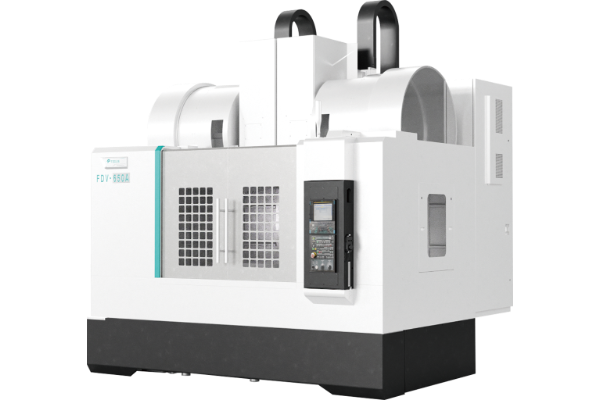

Youjia FDV-650a

1. Double-spindle vertical machining center all-in-one machine "Dual spindles + dual ATC" to achieve high productivity, productivity increased by 2 times, cost reduced by 25%, floor space reduced by 40% Reduce personnel costs and plant operating costs. 2. Double spindle ZNW is an independent servo motor drive and independent structure, which allows independent tool compensation and is not limited by the length of the tool. 3. Double spindle spacing fine adjustment (U axis). Spindle spacing fine adjustment can greatly reduce the setting time of the tool. The same strand movement of U axis + 1mm can be carried out (assembly size deviation compensation of fixture, tool chain compensation in X axis direction, spindle thermal cross compensation)

Main products

CNC machine tool