Company Introduce

MAHATMA mission is to assist in the domestic substitution and industrial upgrading of intelligent manufacturing. Since its establishment in 2003, it has continuously innovated its technological products and solutions in cutting-edge innovation fields such as leveling machines, automated production lines, smart systems, and supporting equipment. We are a sheet metal parts straightening intelligent manufacturing solution service provider that integrates research and development, production, sales, and service. It is a leading international high-end leveling equipment intelligent manufacturing brand with global competitiveness, as well as a national high-tech and specialized new enterprise. As the pioneer of intelligent super leveling technology equipment, Mahat has achieved full category coverage of leveling equipment from low-end to high-end. With more than 20 years of industry accumulation and technological innovation, our manufacturing process and leveling accuracy have reached the most advanced international level.

Exhibit brands

Exhibits

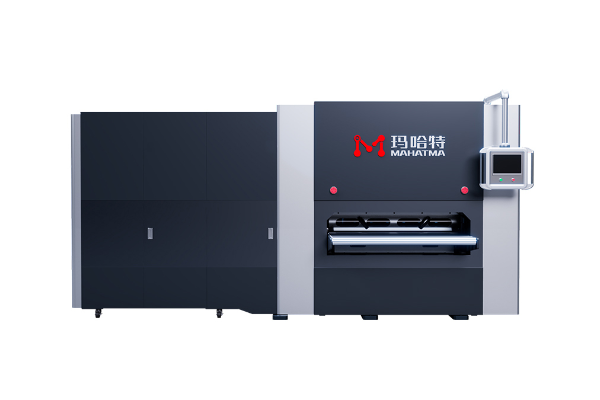

MHT50-1300-19 with assembly line

1. Width: 0-1300mm 2. Thickness: 0.8-4.0mm, yield strength ≤ 260MPA, tensile strength ≤ 450MPA. (Note: the maximum processing thickness and width of the workpiece made of other materials (strength) shall be converted according to the strength.) 3. Diameter of leveling wheel: φ50mm 4. Programming: SIEMENS. 5. Touch screen: SIEMENS. 6. Frequency converter: SIEMENS/Taiwan Delta 7. Leveling quantity: 19 8. Auxiliary wheel: multiple groups up and down, consisting of multiple roller bearings Under the condition of large elastic-plastic bending of metal materials, no matter how different the original bending degree is, the numerical control high-precision flattening machine uses the "Bauschinger effect" of the material to repeatedly bend the plate, gradually reduce the bending deflection, gradually change the original curvature into a single curvature, and flatten it to achieve the flatness accuracy required by the process. The numerical control high flattening machine has been widely used in industry, and has the characteristics of advanced technology, high flattening precision, wide process range, high automation degree, reliable and stable work under high strength, and the like; in the roller flattening process, a workpiece thick plate only needs to be manually inserted, the metal plate is subjected to a series of alternate bending, and the pressing amount of each flattening roller is accurately controlled by a motor and a PLC, The internal stress is eliminated, and the condition that the leveling effect is not ideal due to the fact that the stress of each part of the plate is different is fundamentally solved, so that high-precision leveling is realized.

MHT150-1600-19

1. Width: 0-1600mm 2. Thickness: 6.0-25.0mm, yield strength ≤ 260MPA, tensile strength ≤ 450MPA. (Note: the maximum processing thickness and width of the workpiece made of other materials (strength) shall be converted according to the strength.) 3. Diameter of leveling wheel: φ150mm 4. Programming: SIEMENS. 5. Touch screen: SIEMENS. 6. Frequency converter: SIEMENS/Taiwan Delta 7. Leveling quantity: 19 8. Auxiliary wheel: multiple groups up and down, consisting of multiple roller bearings Under the condition of large elastic-plastic bending of metal materials, no matter how different the original bending degree is, the numerical control high-precision flattening machine uses the "Bauschinger effect" of the material to repeatedly bend the plate, gradually reduce the bending deflection, gradually change the original curvature into a single curvature, and flatten it to achieve the flatness accuracy required by the process. The numerical control high flattening machine has been widely used in industry, and has the characteristics of advanced technology, high flattening precision, wide process range, high automation degree, reliable and stable work under high strength, and the like; in the roller flattening process, a workpiece thick plate only needs to be manually inserted, the metal plate is subjected to a series of alternate bending, and the pressing amount of each flattening roller is accurately controlled by a motor and a PLC, The internal stress is eliminated, and the condition that the leveling effect is not ideal due to the fact that the stress of each part of the plate is different is fundamentally solved, so that high-precision leveling is realized.

MHTY60-1400-21

1. Width: 0-1400mm 2. Thickness: 1.0-8.0mm, yield strength ≤ 260MPA, tensile strength ≤ 450MPA. (Note: the maximum processing thickness and width of the workpiece made of other materials (strength) shall be converted according to the strength.) 3. Diameter of leveling wheel: φ60mm 4. Programming: SIEMENS. 5. Touch screen: SIEMENS. 6. Frequency converter: SIEMENS/Taiwan Delta 7. Leveling quantity: 21 8. Auxiliary wheel: multiple groups up and down, consisting of multiple roller bearings Mahat hydraulic high precision leveling machine uses the hydraulic system and numerical control computing system imported from Germany. The powerful hydraulic pressure keeps the gap (mechanical dead limit) between the upper and lower leveling rollers unchanged all the time, which minimizes the overall deformation of the machine during operation and ensures the consistent leveling effect of large quantities of parts. Parallel multi-roller, hydraulic locking, intensive support and other technologies meet the requirements of high-precision leveling of plane parts. The host structure of the hydraulic press is composed of upper and lower beams and four column pull rods at four corners. The upper and lower rollers are synchronized with electronic speed regulation, and the overload automatic shutdown function is adopted! Two-beam and four-column type left side transmission, the right side of the equipment is open, which is convenient for roller replacement and cleaning. The four hydraulic column pull rods of the upper beam lock the inlet and outlet roller gaps between the upper and lower leveling roller groups. Whether there are sheet parts passing through the machine or not, the inlet and outlet roller gaps are always kept unchanged, which can work continuously, stably and efficiently for 24 hours a year.

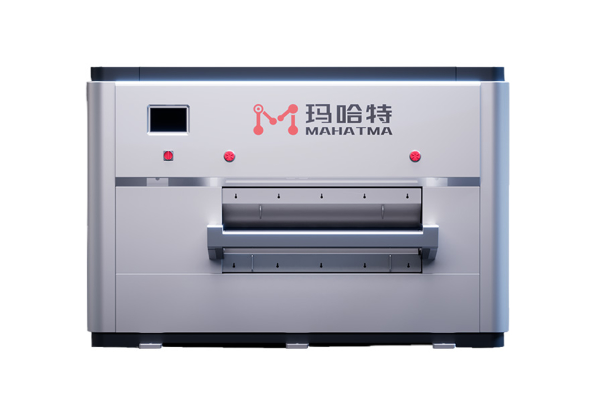

MHT120-1300-19

1. Width: 0-1300mm 2. Thickness: 4.0-16.0mm, yield strength ≤ 260MPA, tensile strength ≤ 450MPA. (Note: the maximum processing thickness and width of the workpiece made of other materials (strength) shall be converted according to the strength.) 3. Diameter of leveling wheel: φ120mm 4. Programming: SIEMENS. 5. Touch screen: SIEMENS. 6. Frequency converter: SIEMENS/Taiwan Delta 7. Leveling quantity: 19 8. Auxiliary wheel: multiple groups up and down, consisting of multiple roller bearings Under the condition of large elastic-plastic bending of metal materials, no matter how different the original bending degree is, the numerical control high-precision flattening machine uses the "Bauschinger effect" of the material to repeatedly bend the plate, gradually reduce the bending deflection, gradually change the original curvature into a single curvature, and flatten it to achieve the flatness accuracy required by the process. The numerical control high flattening machine has been widely used in industry, and has the characteristics of advanced technology, high flattening precision, wide process range, high automation degree, reliable and stable work under high strength, and the like; in the roller flattening process, a workpiece thick plate only needs to be manually inserted, the metal plate is subjected to a series of alternate bending, and the pressing amount of each flattening roller is accurately controlled by a motor and a PLC, The internal stress is eliminated, and the condition that the leveling effect is not ideal due to the fact that the stress of each part of the plate is different is fundamentally solved, so that high-precision leveling is realized.

Automatic leveling production line (unmanned management)

It is suitable for cutting mass production workpieces. The same roll of material cuts a single product. After uncoiling and leveling, the material enters the laser cutting unit. After feeding to the cutting area through the special machine tool structure, the cutting pattern is cut. After that, the cutting rolling platform conveys the cut material to the belt assembly line for sorting or automatic palletizing. Ceiling industry, aluminum curtain wall industry, cold-rolled plate chassis cabinet, elevator, electrical cabinet, ventilation pipe industry, etc. Compared with the traditional coil slitting line/flat laser cutting machine, this machine can cut different products at will, can produce automatically, save more material costs, can meet the application needs of different customers, and has a wider range of applications.

MHTP High-end Series High Precision Leveler

1. The upper and lower rollers can be drawn out automatically (convenient for cleaning the rollers) 2, automatic calculation of quantity (can be connected to various MRP, ERP system control, automatic setting and monitoring of equipment boot time, effective working time and automatic counting of the number of processing parts) 3. Full support (the whole roller is fully supported with strong structural force) 4. Automatic monitoring function (convenient for monitoring equipment and production conditions at any time, and convenient for repair and maintenance) 5. Support shaft (the design of wide support improves the running rigidity of the leveling roller) 6, remote control function (for customers in remote areas, our engineers can help customers at any time to solve problems such as machine adjustment, equipment failure, etc.) 7. BMW paint (using high-end BMW paint, the whole machine is high-end and luxurious) 8. Automatic flatness detection (automatic scanning accuracy detection, OK)

Main products

Servo CNC high precision leveling machine, hydraulic high precision leveling machine, four (six) heavy leveling machine, automatic loading and unloading manipulator, robot, laser leveling detector, high precision uncoiling and leveling stamping shear line and laser cutting automatic production lines