Company Introduce

Dongguan JS Tech Limited is a stamping automation equipment manufacturer integrating R&D, manufacturing, sales and service. Committed to R&D and production of stamping automation equipment, providing rich stamping automation solutions for forging equipment manufacturers and stamping companies. The company introduces international advanced design concepts from Germany, Italy, the United States, Japan, Taiwan and other counterparts, independently develops, produces and sells. The main products are 3-in-1 servo feeding line, ultra-high-speed dual-servo feeding production line, CNC Zigzag feeding line, progressive stamping automatic feeding line, blanking line, and various automatic stamping 2D/3D transfer system, multi-press transfer system, customized turn-key automation solutions etc.JS TECH products are widely used in the automobile industry, home appliance industry and other various hardware manufacturing industries. In order to better serve customers in the Yangtze River Delta region, Yangzhou LSL Intelligent Equipment Co., Ltd. was established in 2023, which perfectly cooperated with Dongguan JS Tech Limited to provide close services for the Yangtze River Delta and the Pearl River Delta, the two major economic frontiers of the country. The company's products are exported to Europe, South Africa, North America, India and Southeast Asian countries, the company from the business, research and development, services to create a full range of international advantages, remote support, and local service providers supporting localized services, so that all parts of the world can enjoy high cost-effective high-end automation equipment and services.

Exhibit brands

Exhibits

High precision leveling machine

High precision flattening machine is a kind of equipment used to straighten and flatten sheet metal. It is mainly used to eliminate the internal stress of sheet metal so as to achieve the flattening effect. Product features: · Improve the leveling effect of the steel strip. The traditional leveling machine can only achieve the leveling accuracy of 1.5mm/m2, while our new leveling machine can achieve the leveling accuracy of 0.1 ~ 0.3mm/m2. · The high-precision leveling machine can be applied to blanking lines with high flatness requirements, laser cutting lines, shearing lines and other continuous stamping lines with high requirements. · Especially for the pre-punching processing of high-strength steel for automobiles with higher strength, and the post-punching processing of mesh plates, saw blades, sprockets, etc.

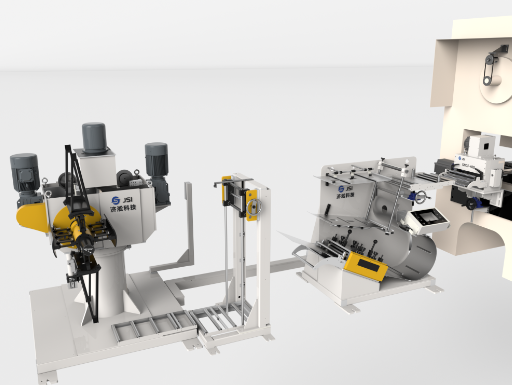

High-speed double-servo feeding lines

High-speed double servo feeding line is an efficient automation equipment, mainly used in stamping production, which can significantly improve the production efficiency and feeding accuracy. High-speed machine features: 1. Release Method: Servo Release 2. Servo automatic adjustment of material thickness. When the material thickness changes, simply input a new material thickness on the screen. The servo automatic adjustment is fast and accurate, reducing feeding errors and material waste caused by manual adjustment errors. The thickness of this material can be stored according to the product formula, achieving one click adjustment of parameters to replace the product. 3. The servo automatically adjusts the threading height, and the roller lifting height is set on the screen and stored together with the product formula. 4. Multifunctional wireless manual operation box, including functions: emergency stop, start, stop, release, press down, return point action/return point action one stroke, feed point action/feed point action one stroke, feed single action, mode switching (manual, automatic, debugging); The manual operation box contains all functions except for parameter settings, making it easy to use and can effectively protect the touch screen, extending its lifetime. 5. Gear lubrication with oil, the entire gear is immersed in the oil tank, silent, and has a long lifetime. 6. Use the German made Norgren airbag buffer to minimize and stabilize the impact caused by relaxation. 7. The electrical cabinet adopts CE standard, with a protection level of IP65, effectively waterproof and dustproof. 8. Install a protective cover on the touch screen for safety and reliability 9. The entire machine is positioned and installed through positioning pin, firmly connected, not affected by vibration, and has stronger stability in service life.

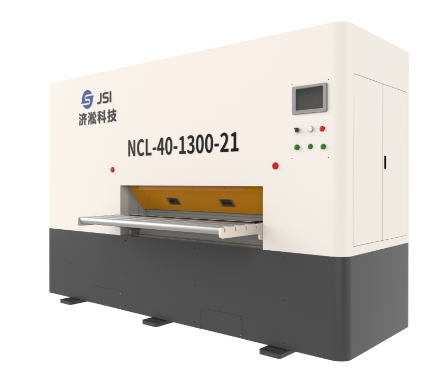

NCL-40-1300-21 Precision Leveling Machine

Features: · 21pcs leveling rollers, supported by strong support rollers from upsideand downside, achieve high-strength and high-precision leveling. · The flatness accuracy can reach within 0.05mm. · Materials Yield strength greater than 980Mpa can be leveled. · Widely used in laser cutting, metal stamping, mechanical processing, saw blades, mesh plates, discs, and copper and iron · Adding a support adjustment mechanism can achieve both horizontaland vertical leveling in one time.

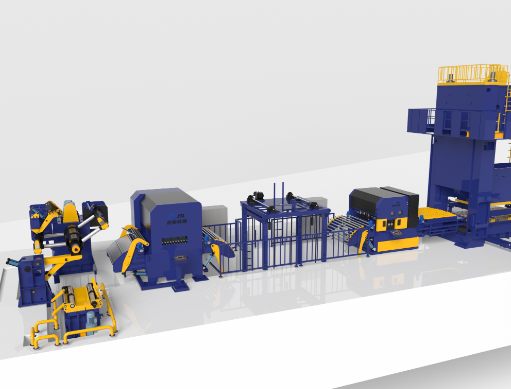

1600 T 3D Transfer System Continuous Stamping Line

Advantages and features: • Efficient: up to 30 times/min • One-touch die change • Meets the most stringent CE safety requirements • Full-line SIEMENS system, bus PROFINET communication control.

20-600 high precision leveling machine

High precision flattening machine is a kind of equipment used to straighten and flatten sheet metal. It is mainly used to eliminate the internal stress of sheet metal so as to achieve the flattening effect. Main parameter: · Material Width: 0 ~ 600mm · Material Thickness: 0.1-1.2mm · Leveling Roller: 23pcs,upper 11/ down 12) · Support Roller: 3 groups at upper and lower parts respectively · Leveling speed: 0 ~ 8 m/min · Shortest workpiece: 40mm · Leveling adjustment method: hand wheel · Leveling accuracy: ≤ 1.5mm/m2 · Voltage: 380V 3P 50Hz (customizable)

Main products

The main products are 3-in-1 servo feeding line, ultra-high-speed dual-servo feeding production line, CNC Zigzag feeding line, progressive stamping automatic feeding line, blanking line, and various automatic stamping 2D/3D transfer system, multi-press transfer system, customized turn-key automation solutions etc.