Company Introduce

Established in 2014, Dongguan Kunrui Precision Machinery Technology Co., Ltd. is a high-tech enterprise specializing in the research, development, production and sales of shaft precision testing instruments, located in Chang'an Town, Dongguan, Guangdong Province. The company has a wide range of business, mainly covering research and development, production and marketing, maintenance of precision machinery and accessories, measuring instruments, hardware accessories, hardware tools, plastic accessories, cutting tools and so on. The company has independently developed and manufactured milling cutter measuring instrument, which combines KYENCE laser technology to complete the detection of milling cutter outer diameter, jumping blade height difference and other parameters in a non-contact way, avoiding the damage of traditional contact-type me asurement to the cutter, ensuring micron-level high-precision results, and also has multi-functional detection capabilities to meet the needs of complex processing scenarios. It is suitable for real-time quality control on the production line. The company has always adhered to the customer-centric, to provide customers with high-quality products, good technical support and sound after-sales service. With professional, sincere and fast service attitude, we solve all kinds of problems for customers, provide perfect technical solutions, and establish a good reputation in the industry. In the future, Dongguan Kunrui Precision Machinery Technology Co., Ltd. will continue to innovate, constantly enhance its own strength, and provide better and more efficient precision testing equipment and services for various industries.

Exhibit brands

Exhibits

Round Nose Knife Ball Knife Measuring Instrument

The milling cutter tester adopts advanced laser technology, which can accurately measure the maximum rotating outer diameter, maximum outer diameter, milling cutter runout and height difference of each edge of the single-double-edge milling cutter without contacting the milling cutter, with zero damage to the cutter. High-precision ceramic "V" groove, theoretical 0 runout tolerance, outer diameter accuracy up to ± 0.0015mm, runout accuracy up to 0.0025 mm. The measurement speed is amazing, the fastest 3 seconds can complete the measurement of the outer diameter of a milling cutter, efficient and accurate. Different from the traditional measuring instrument, the new appearance detection function, using high-definition image recognition technology, can quickly detect the wear, chipping, cracks and other defects on the surface of the milling cutter. The system will automatically compare the test results with the standard image, and once an abnormality is found, it will immediately give an alarm and record, providing a more comprehensive guarantee for the quality and life of the tool.

Automatic milling cutter measuring instrument

This product is based on the function of traditional milling cutter measuring instrument. Comprehensive technical upgrade, not only inherited the diameter, jump, circle High precision measurement of basic parameters such as cylindricity and coaxiality Force, more breakthrough, new ball knife and round nose knife angle measurement power It can realize the full coverage of tool detection. Through intelligent, complete, Closed design and one-click operation process, redefining milling Efficiency and reliability criteria for knife measurement. As well as a ball knife and a circle. Measurement of the angle of the nose knife.

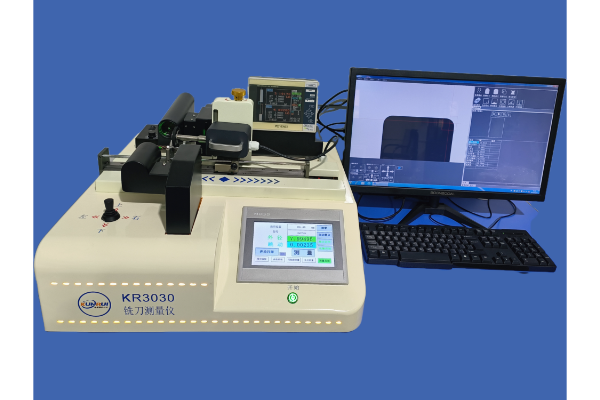

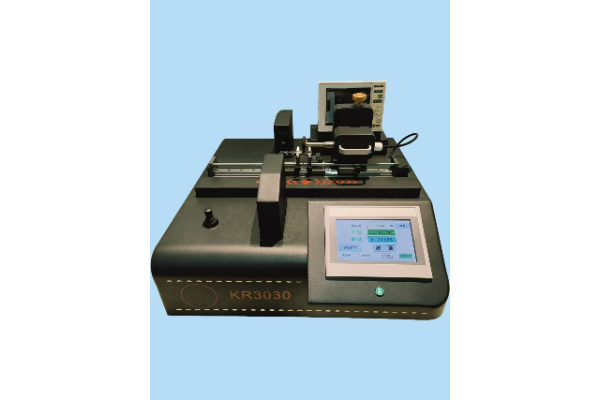

Milling Cutter Measuring Instrument

This tester uses advanced laser technology to accurately measure single-edge and double-edge milling cutters without touching the milling cutter. Maximum rotary outer diameter, maximum outer diameter, milling cutter runout, height difference of each cutting edge, coaxiality and cylindricity, etc., zero for the cutter Damage. High-precision ceramic "V" groove, theoretical 0 runout tolerance, outer diameter accuracy up to ± 0.0015mm, runout precision Degree up to 0.0025 mm. The measuring speed is fast, and the outer diameter runout measurement of a milling cutter can be completed in 3 seconds at the fastest, which is efficient and Precise. KR3030B's new appearance detection function, using high-definition image recognition technology, can quickly detect the grinding of milling cutter surface Damage, chipping, cracks and other defects provide a more comprehensive guarantee for the quality and life of the tool. CCD can be used as an image sensor to convert the sample image under the microscope into electrical signals and display them on the computer screen. In this way, scratches and pits on the surface of the product can be easily observed. At the same time, image analysis and measurement can be carried out.

Milling Cutter Outer Diameter Measuring Instrument

No need to touch the tool, quick single/double in 3 seconds Edge milling cutter measurement to avoid tool damage. Supported measurement items: maximum outer diameter, minimum outer diameter, Runout value, blade height difference, coaxiality, cylindricity, etc. Adopt high-precision ceramic "V" groove, theoretical 0 runout Tolerances to ensure stability. The outer diameter measurement accuracy is ± 0.0015mm, and the run-out accuracy is 0.0025mm, which meets the requirements of high-precision tool detection.

Main products

Design and customized development of milling cutter testing equipment, alloy bar, shaft testing equipment and non-standard testing equipment