Company Introduce

Changzhou Like Intelligent Machinery Co., Ltd. focuses on the R & D and manufacturing of high-end tool magazines. The company has been rooted in Changzhou, Jiangsu Province for more than ten years, and has been deeply engaged in the field of automatic tool change, providing core tool change solutions for engraving and milling machines, vertical, horizontal, gantry machining centers, five-axis machining centers, spark machines and other equipment. After the strategic upgrade in 2022, relying on senior technical team, international advanced processing equipment and more than 30 patented technologies, the company continued to break through the manufacturing bottleneck of the tool library, and the product performance was in the forefront of the industry. As a state-level high-tech enterprise, a private science and technology enterprise in Jiangsu Province and a national credit demonstration unit, the company's products are exported to manufacturing powers such as the United States, Germany and Japan, and are highly recognized by customers at home and abroad for their high-precision and long-life characteristics. It is equipped with a professional after-sales team to provide 7 X 24 hours technical support to ensure the stable operation of the equipment throughout its life cycle. Adhering to the concept of "winning the first choice with super-value products and services", the average annual R & D investment of enterprises accounts for more than 15%, and through ISO quality management system certification, the whole process of quality control from raw material procurement to finished product delivery is realized. In the future, the company will deepen the implementation of the technical commitment of "as long as the earth does not stop turning, the knife library will not stop turning" to provide sustained momentum for the transformation and upgrading of intelligent manufacturing.

Exhibit brands

Exhibits

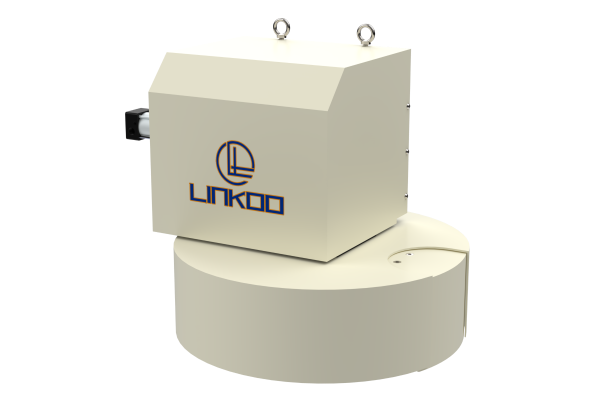

Chain type hydraulic vertical and horizontal tool magazine

The tool changing mechanism is hydraulic, which can grasp heavy and long tools, and can be used both vertically and horizontally, and can be customized. The motor is a famous brand in Taiwan and has passed the European Union 3C certification. The whole series of electronic switches adopt imported original parts with guaranteed quality.

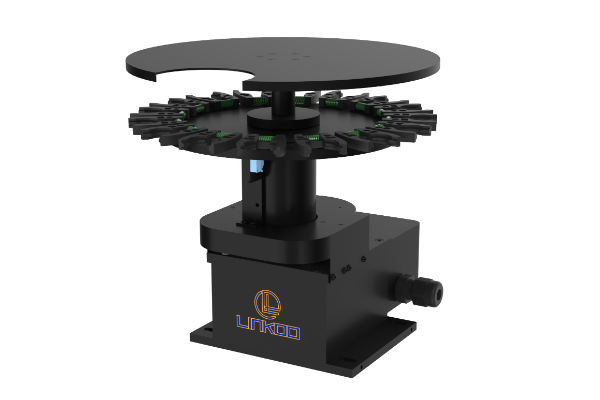

Disc vertical tool magazine

The cylindrical cam cutting mechanism has the advantages of high cutting precision, low failure rate and high transmission efficiency. The structure is simple and the maintenance is more convenient. Separated tool arm, high concentricity, low noise, high strength, not easy to deform and easy to maintain. The motor is a famous brand in Taiwan and has passed the European Union 3C certification. The whole series of electronic switches adopt imported original parts with guaranteed quality.

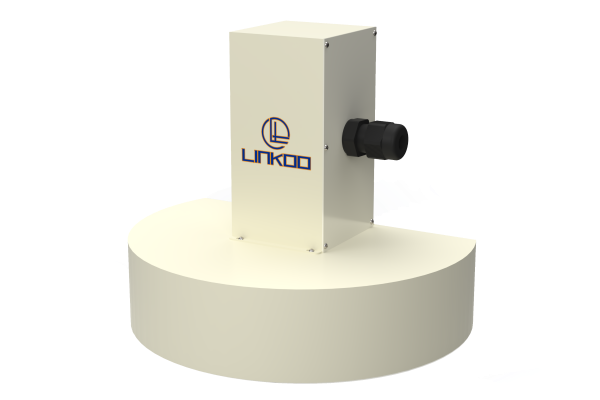

Disc horizontal tool magazine

The cylindrical cam cutting mechanism has the advantages of high cutting precision, low failure rate and high transmission efficiency. The structure is simple and the maintenance is more convenient. Separated tool arm, high concentricity, low noise, high strength, not easy to deform and easy to maintain. The motor is a famous brand in Taiwan and has passed the European Union 3C certification. The whole series of electronic switches adopt imported original parts with guaranteed quality.

Vertical chain magazine

The cylindrical cam cutting mechanism has the advantages of high cutting precision, low failure rate and high transmission efficiency. The structure is simple and the maintenance is more convenient. Separated tool arm, high concentricity, low noise, high strength, not easy to deform and easy to maintain. The motor is a famous brand in Taiwan and has passed the European Union 3C certification. The whole series of electronic switches adopt imported original parts with guaranteed quality.

Horizontal chain magazine

The cylindrical cam cutting mechanism has the advantages of high cutting precision, low failure rate and high transmission efficiency. The structure is simple and the maintenance is more convenient. Separated tool arm, high concentricity, low noise, high strength, not easy to deform and easy to maintain. The motor is a famous brand in Taiwan and has passed the European Union 3C certification. The whole series of electronic switches adopt imported original parts with guaranteed quality.

Servo semi-circular tool magazine

1, lightweight, aluminum alloy cutterhead, reduce the load. And 2, that Geneva wheel split mechanism is adopted, so that the operation is smooth, and the split precision is high. And 3, that cut head slides by use a line rail, so that the rigidity is good, the load is high, the friction is small, the cutter head is quieter, and the service life is long. 4. The tool holder is made of raw materials imported from DuPont of the United States. It is light in weight and can still operate well in harsh environments. The temperature difference range can reach 120 °. It can resist high temperature of 80 ° and low temperature of -40 °. It has high toughness and strength and is not easy to be damaged. 5, the whole series of electronic switches using imported original, quality assurance.

Bamboo hat type tool magazine

1, lightweight, aluminum alloy cutterhead, reduce the load. And 2, that Geneva wheel split mechanism is adopted, so that the operation is smooth, and the split precision is high. And 3, that cut head slides by use a line rail, so that the rigidity is good, the load is high, the friction is small, the cutter head is quieter, and the service life is long. 4. The tool holder is made of raw materials imported from DuPont of the United States. It is light in weight and can still operate well in harsh environments. The temperature difference range can reach 120 °. It can resist high temperature of 80 ° and low temperature of -40 °. It has high toughness and strength and is not easy to be damaged. 5, the whole series of electronic switches using imported original, quality assurance.

Umbrella magazine

1, lightweight, aluminum alloy cutterhead, reduce the load. And 2, that Geneva wheel split mechanism is adopted, so that the operation is smooth, and the split precision is high. And 3, that cut head slides by use a line rail, so that the rigidity is good, the load is high, the friction is small, the cutter head is quieter, and the service life is long. 4. The tool holder is made of raw materials imported from DuPont of the United States. It is light in weight and can still operate well in harsh environments. The temperature difference range can reach 120 °. It can resist high temperature of 80 ° and low temperature of -40 °. It has high toughness and strength and is not easy to be damaged. 5, the whole series of electronic switches using imported original, quality assurance.

Main products

Disk vertical tool magazine, disk horizontal tool magazine, chain tool magazine, hydraulic vertical and horizontal dual-purpose tool magazine, engraving and milling machine servo tool magazine, spark machine tool magazine, turning and milling composite tool magazine, grinder tool magazine, woodworking tool magazine, etc.