Company Introduce

PMT Technologies, abbreviated as PMT, is a high-tech company specialized in measurement technology. With fully independent capabilities in research, development, and production, PMT has gained abundant experience in different fields for years, including portable measurement, optical measurement and encoder. We follow European standards in research, development and production, and always act on the idea of cutting-edge technologies. We carry forward the spirit of craftsmanship from Germany, and control the product quality to the best of our ability. PMT has been promoting a high quality development with innovation and technologies in global measurement field. For the past 20 years, PMT has been deeply rooted in this field, and obtained many patents for its core technologies. PMT prioritizes its commitment to research and development, and keeps investing huge amount of money in pursuing long-term cooperation with world-class research institutes and expanding its technology bases. With support from the Darmstadt University of Technology, PMT has achieved product authentications by European standards. PMT has set up research centers in China, Germany and Japan. In China, we have production bases in Suzhou. We have also broadened our sales service network to cover China’s major industrial cities with the aim at providing prompt and professional technical support. Looking ahead, spearheaded by technological innovation, PMT will stay committed to the mission of making measurement more accurate and professional. Together, we will step up efforts to create values, make progress, and beat customer’s expectation. All these efforts are aimed at fulfilling our strategic goals and social values in the long run.

Exhibit brands

Exhibits

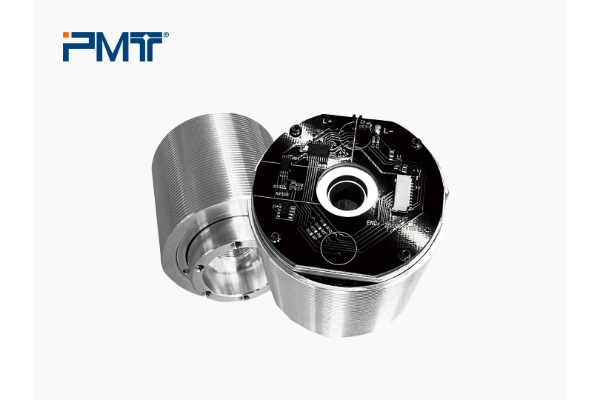

PMT High Accuracy Encoder

PMT high accuracy encoder is the core unit of the measuring arm, and its performance directly determines the overall measurement accuracy and spatial positioning reliability of the measuring arm. This series of encoders provides real-time, accurate angular feedback for each rotational joint of the measuring arm. The angle measurement error of that encode can be controlled at the level of a few arc second, and the encoder only needs the basic power supply of a sensor and a chip by virtue of an extremely low pow consumption design, so that the encoder is very suitable for being integrated into a portable and battery-powered measuring arm device, and the continuous working time of the device is prolonged while the performance is ensured. In addition to measuring arm systems, the encoder is also widely used in machine tool rotary tables, coordinate measuring machines, precision turntables, optical instruments and automation equipment.

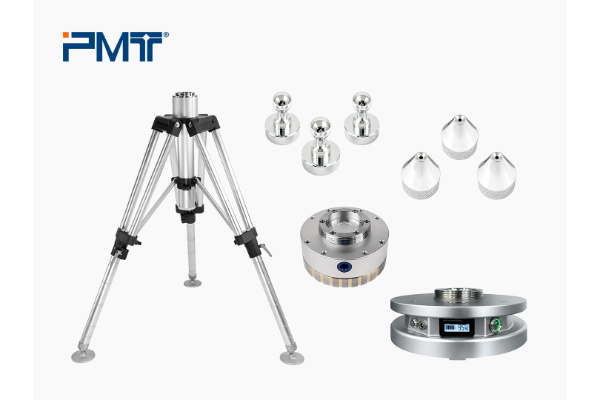

PMT Measuring Accessories

PMT's self-produced measurement accessories are dedicated to providing stable and flexible field support for all kinds of precision measurement equipment, especially for measuring arm and laser trackers, which can significantly improve the portability and installation efficiency of measurement work. PMT Folding Tripod Universal measuring platform, compatible with various types of high-precision measuring equipment, provides a stable and adjustable installation benchmark for measuring arm and other instruments, and adapts to various environments such as workshops and laboratories. PMT Magnetic Mount It is suitable for rapid adsorption and installation on metal surface, can firmly fix measuring equipment, expand the scope of operation, and facilitate the rapid establishment of temporary measuring stations on the production site. PMT Electric Vacuum Clamping Plate Through one-key adsorption technology, it can achieve stable installation on smooth and non-porous table, provide reliable benchmark for precision measurement, and meet the requirements of precision detection, quality control and reverse engineering with high stability. PMT Magnetic Sphere/Magnetic Cone Support leapfrog measurement expansion, magnetic base to ensure stable positioning, each group contains three, two forms of sphere and cone can flexibly adapt to different measurement needs, effectively expand the working range of equipment.

PMT ALPHA Measuring Arm Series

PMT ALPHA Measuring Arm Series adopts the built-in balance mechanism most suitable for on-site measurement and the design of equal arm length, with simple and balanced structure, flexible operation and bold innovation in details. Each PMT arm is subjected to rigorous extreme temperature cycling tests (-20 ° C to 60 ° C), shock and vibration tests in accordance with IEC standards. Strict accuracy verification is carried out in accordance with ISO 10360 international standards to ensure the accuracy, consistency and reliability of measurement in various environments. On this basis, the ALPHA EDU Measuring Arm, which is specially designed for the field of education, further expands the application possibilities. It supports different ranges and measurement forms, not only provides 6-axis/7-axis options, but also carries SD/HD scanning heads to help students go out of the campus to enhance their competitiveness. It has cooperated with many well-known universities and vocational colleges at home and abroad.

PMT GAMMA Measuring Arm Series

PMT GAMMA Measuring Arm Series adopts the world's first external decoupling built-in balance and double suspension support mechanism, with low power consumption, black technology, excellent performance and flexibility. Equipped with GS/GH blue light scanning head, it can achieve non-contact detection performance, especially suitable for the detection of parts with complex curved surface, soft and fragile surface or easily damaged by contact, covering all the detection elements. The device can be used with an 8-axis power-assisted turntable. The workpiece is fixed on the turntable, and only the turntable needs to be rotated without moving the position of the joint arm during detection, so that efficient 360-degree omni-directional scanning can be realized, and the measurement efficiency and the operation convenience are greatly improved. The measurement rate can reach 1200000 data points per second, which can quickly obtain high-density point clouds and generate inspection reports with PMT INSPECT three-dimensional measurement software. It is widely used in reverse modeling, surface comparison and digital filing of sheet metal parts, automotive interiors and other fields, providing users with efficient, accurate and complete three-dimensional solutions.

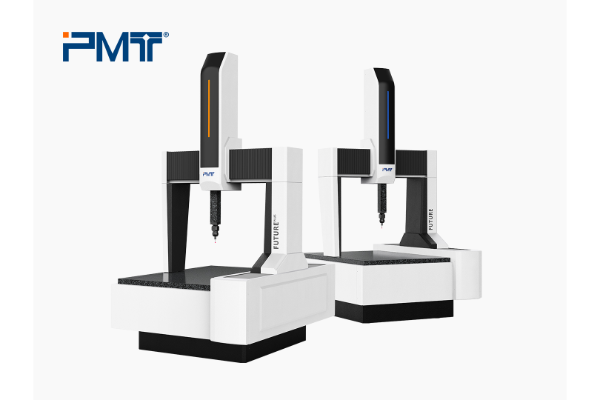

PMT FUTURE Coordinate Measuring Machine (CMM)

PMT FUTURE series bridge-type CMM covers two models of FUTURE PLUS and FUTURE. It is the high-end CMM equipment of PMT. It can meet the needs of ultra-high precision detection of complex parts. It has the characteristics of high efficiency and stable performance, and helps to achieve precision machining, assembly and quality control. PMT FUTURE CMM, with its excellent performance, provides high-precision, high-stability and high-efficiency measurement solutions for production sites, R & D centers and metrology rooms, and is widely used in automotive, mold, machining, precision manufacturing, metrology institutes, aerospace and other fields. With its micron-level high precision, excellent stability and efficient dynamic measurement performance, it provides a reliable guarantee for the precision detection, assembly verification and quality control of complex parts in the above industries.

PMT PRIME Coordinate Measuring Machine (CMM)

PMT PRIME CMM adopts structure of equilateral triangle beam design and aviation aluminum alloy frame structure, which has the best structural rigidity ratio and aims to provide customers with higher accuracy, long-term stability and higher dynamic performance. Accuracy is between 2.8 μm and 3.4 μm, and there are six models to choose from. The PMT PRIME bridge-type coordinate measuring machine provides an excellent balance between the pursuit of high-precision measurement and cost control.

PMT INSPECT 3D Software

PMT INSPECT is an industrial 3D measurement software independently developed by PMT, which has military-grade data security guarantee and ensures the safety and controllability of the whole process of measurement data through multi-modal encryption strategy and independent core algorithm. The software is widely compatible with mainstream measuring equipment such as measuring arm and coordinate measuring machine, and can dock with most of the mainstream hardware in the world to fully release the performance of the equipment. At the same time, it fully supports STEP, IGS and other digital and analog formats, as well as PCD, TXT, XYZ, ASC, CSV, PLY, OBJ, STL and other point cloud and triangular grid formats, to ensure smooth data interaction between platforms. Its built-in powerful data processing and analysis engine provides a complete set of solutions from basic size detection to complex surface analysis. Whether it is accurate point measurement, fast reverse engineering, or rigorous geometric tolerance comparison, PMT INSPECT can be completed efficiently to fully meet your diverse high-precision measurement needs.

PMT Measuring Arm with I-Fork Probe

Aiming at the problem of accurate measurement of flexible and deformable workpieces such as elbows and hoses, PMT has launched a new product, PMT Measuring Arm with I-Fork Probe. The equipment can quickly and accurately measure the data of bending angle and pipe size without touching the surface of the workpiece, and evaluate the form and position tolerance. For the soft and deformable pipeline which is difficult to measure by traditional methods, this equipment can show its unique advantages, while ensuring the measurement accuracy, it can perfectly protect the workpiece surface intact.

Main products

PMT ALPHA Measuring Arm Series PMT GAMMA Measuring Arm Series PMT Measuring Arm with I-Fork Probe PMT FUTURE Coordinate Measuring Machine (CMM) PMT PRIME Coordinate Measuring Machine (CMM) PMT INSPECT 3D Software PMT High Accuracy Encoder PMT Measuring Accessories