Company Introduce

Jieyongda was founded in 1995, more than 20 years focused on mold processing and mechanical parts processing equipment. R & D, manufacturing, has formed a high-quality, high-performance product R & D, manufacturing, service team and rigorous Efficient operation system, from ordinary milling machines to machining centers, manipulators, automation of the eleven The product line covers more than 40 major economically developed cities in China and more than 20 countries in Asia, Europe and the United States. Home. The company takes the high quality product as the localization, provides the most suitable high quality product for the customer for the research and development thought. Want to become a domestic mold and mechanical parts processing equipment for the field of full product line, and has a strong tailor-made. Design capabilities of professional equipment manufacturers.

Exhibit brands

Exhibits

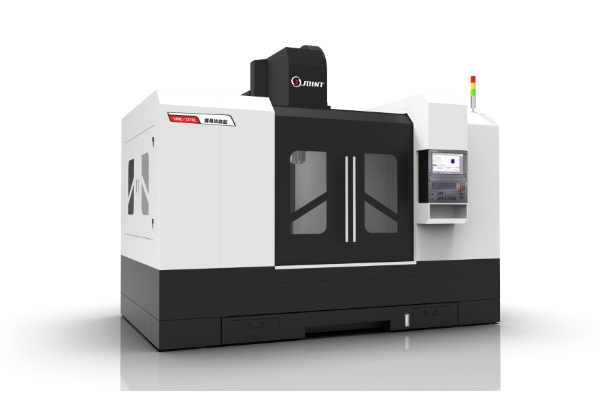

Machining center for recut die blank VMC-1175BL3

The whole machine takes heavy cutting and rigid processing as the basic design starting point, super rigid structure and large torque heavy load spindle, 1175BL3 can achieve efficient deep cutting and strong cutting, greatly improve the processing efficiency of mould and mould blank, and win the delivery time.

High Speed Parts Machining Center VMC-V855H

And has that characteristic of high feed speed and high rotate speed efficiency. Applicable to complicate, multiple working procedure and various cutting tools and tooling, A part that has been processed into a batch. It mainly processes boxes, complex surfaces, special-shaped parts, discs, sleeves and plates, which are widely used in electronics, machinery, automobiles, automation, medical treatment, national defense and other fields. Faster, more refined, more economical, cost-effective choice for high-end mold manufacturing

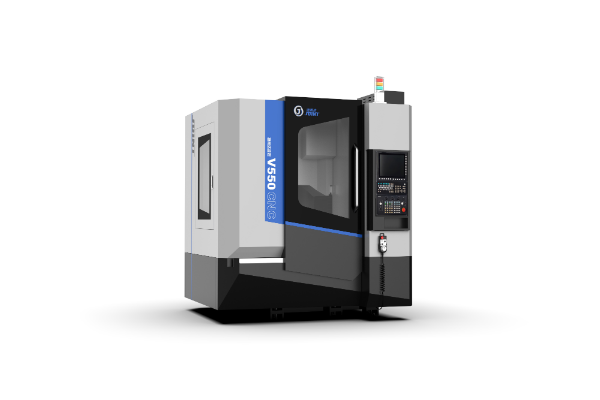

Precision 5-axis machining center V550-5AX

Five axes of Zhilian create infinite effects. A benchmark for integrated solutions for complex parts. According to the five-axis linkage machining center, the machining of five surfaces can be completed by clamping a workpiece once, and meanwhile, the running precision and rigid cutting are more stable, so that the machining efficiency and the machining precision are greatly improved. To meet the automotive parts mold, impeller, blades and other complex parts processing. Widely used in aviation, aerospace, automobile, mold, precision medical equipment, shipbuilding, textile and other manufacturing industries. It plays an irreplaceable role in aviation, aerospace, military, scientific research, precision instruments, high-precision medical equipment and other industries.

Gantry machining center BTMC-1520

BTMC-1520 gantry machining center comprehensively improves the accuracy of large vertical machining center and heavy load, with relatively high accuracy. It is widely used for heavy mold processing, or larger size mold frame, box parts, plate processing, etc. Can also configure BT40-12000/15000 high-speed mechanical spindle, or 18000/24000 high-speed HSK63 electric spindle, add temperature compensation function, to achieve high-gloss mold or part processing.

.png)

Horizontal Machining Center NCM-1160LR

This series of horizontal machining centers focus on excellent overall rigidity, large cutting force, with ultra-wide span, greatly enhance the load, uniform locking force of the worktable, to ensure the rigidity of the worktable. Widen the base and lower saddle to improve the rigidity and stability of fast movement. The fine design of the outer cover ensures the sealing and environmental protection advantages of the equipment.

Precision vertical machining center GBC-650

The GBC-650 is a precision vertical machining center with a marble body. It is suitable for the processing of aerospace aluminum structural parts, automotive plastic dies, stamping dies and high-speed and high-precision parts. In particular, the X, Y and Z axes adopt a high-rigidity driving structure and are equipped with a high-thrust linear motor, which is suitable for the special requirements of high-precision fixture, precision multi-cavity rubber mold and high-precision electrode processing, such as the fine processing of optical and acoustic components, semiconductor components, new energy battery shells and the like in mobile phones.

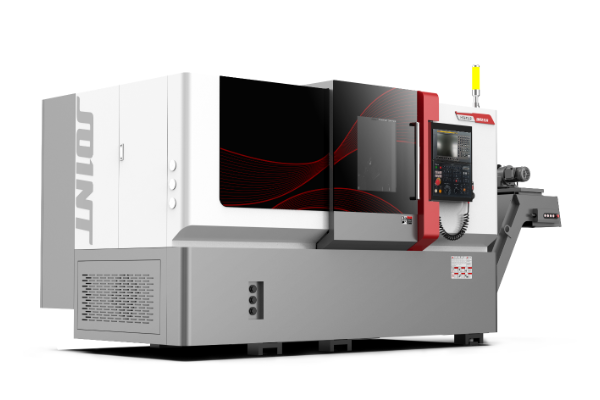

Powerful precision CNC turning and milling compound HTC-5671

Imported or domestic high-performance CNC system and its supporting motor and drive are used to realize two-axis linkage processing. Equipped with high-precision sleeve spindle, with high precision, high speed, stable operation and other characteristics, optional hydraulic Chuck and elastic Chuck, can effectively save workpiece clamping time. Electric turret, hydraulic turret and servo turret can be selected. The machine is suitable for machining large parts, such as thread, circle, cone, etc. Widely used in automotive industry, electronics industry, motorcycles, household appliances, furniture, lighting and other industries in the processing of rotating products.

Main products

Main products: high-precision mold machining centers, high-speed parts machining centers, gantry machining centers, horizontal machining centers, precision five-axis machining centers, engraving and milling machines, CNC lathes, milling machines, grinders, spark machines, automation solutions, etc. Special advantages: Product quality, high stability, continuous research to create zero failure products Fast and practical customized products, quickly tailored to customer needs Equipment application technology support programming technology, processing parameter optimization, fixture matching Complete product supporting program, cutting, milling, grinding, electricity, drilling and other complete supporting. Automatic supporting integration, automatic transformation, automatic loading and unloading