Company Introduce

Yantai BOSEN Science & Technology Development Co., Ltd. was founded in May 1993, which is specialized company in the field of manufacturing for machine tool accessories in China. Our main products consist of: Hinged belt chip conveyor -Compound chip conveyor -Permanent magnetic chip conveyor -Scraper and magnetic scraper chip conveyor -Drop-forged rivet less chain scraper chip conveyor -Screw chip conveyor -Paper band filter -Magnetic roller paper band filter -Integrated chip conveyor with filtering and cooling device -Vertical paper band filter -Vertical circulating filter -Vacuum circulating filter -Coolant central filtering system -Cyclone separator -Oil skimmer -Self-cleaning filter -High speed centrifuge -Single double shaft chip reducer and other functional parts. We have a wide range of products which apply in numerical control machine, internal combustion, automobile, high-speed rail, military enterprise, shipping industry, metallurgy, environmental protection and other industries and exported with main machine together to many countries. Our company is an industry standard drafting unit that "The automatic chip device for CNC", “The automatic filtering device for CNC" industry standard drafting unit, and above two standards formally released and implemented in2014. We have passed ISO 9001:2019 international quality management system certification and get the award of national high and new technique enterprise, China specialization and special new "ittle giant" enterprise, enterprise technology center of Shandong province. Sincere cooperation, high quality product and perfect service are our Bosen's presentation to the society and the world.

Exhibit brands

Exhibits

High-Precision Vertical Paper Band Filter System

This device consists of a liquid tank, a sludge collection tank, filter paper, a reducer, a transmission mechanism, a signal mechanism, and a supply pump, among other components. During operation, it uses filter paper to separate fine chips and impurities from the coolant. When contaminated liquid enters the filtration chamber through the inlet and passes through the filter paper, fine chips and impurities are adsorbed onto the surface of the paper, gradually accumulating until the paper becomes clogged. At this point, the contaminated liquid level rises, causing a float to lift and triggering the signal mechanism. The reducer then drives the mesh chain to move, discharging the impurities and dirty filter paper into the sludge collection tank, thereby achieving automatic filter paper replacement. Once the filter paper is renewed, the contaminated liquid level drops, the reducer stops operating, and the device enters the next work cycle, with all operations controlled automatically. The filtered clean liquid is transported to the main machine by the supply pump. This device extends the service life of the supply pump and coolant, improves the surface precision of machined parts, occupies a small footprint, and achieves a filtration accuracy of 20–30 μm.

Vacuum Circulating Filter Device

The vacuum circulating belt filtration unit is primarily used in high-precision grinding fields such as gear grinding machines, CNC thread grinding machines, and honing machines, delivering excellent performance and economic benefits. This device achieves breakthrough innovations in high-flow, high-precision filtration within limited space, synchronized operation under unified CNC machine control, and more. It utilizes a double-layer woven filter belt as the filtration medium, employs negative pressure suction to separate solids from liquids, and dries the filter cake under vacuum to reduce cutting fluid loss. With a filtration flow rate of 3 m³/min per square meter—approximately 100 times that of traditional filtration methods—the filter cake exhibits a moisture content below 5%, and filtration accuracy reaches 20–30 μm. The system offers advantages such as high-flow filtration, no consumables, high precision, compact footprint, and ease of on-site installation. Its technology meets international advanced standards and possesses independent intellectual property rights, realizing efficient autonomy and localization of suction circulating belt filtration units. This promotes the recycling of machine tool cutting fluid resources and plays a significant role in energy conservation, emission reduction, and resource saving in the machining industry.

Self-Cleaning Chip Conveyor and Filter Device

This chip conveyor and filtration device is suitable for various special-purpose machines and machining centers that require high precision in coolant filtration. It is used for the separation of short chips such as aluminum chips and cast iron chips, as well as the filtration of coolant. The device mainly consists of several key modules: a scraper/magnetic scraper conveyor, a drum filter, an oil-water separator, a liquid level detection unit, an electrical control system, a coolant tank, and a fine filter. Its features include automatic drum cleaning, continuous filtration, high filtration accuracy, maintenance-free operation, and no consumable parts, fully meeting the filtration requirements for chip flushing, spindle internal cooling, and tool cooling in machining centers. Since both special-purpose machines and machining centers have strict requirements regarding chip removal volume, coolant filtration accuracy, as well as coolant pump flow rate and pressure, users are advised to provide relevant technical parameters when placing an order to ensure proper design adaptation.

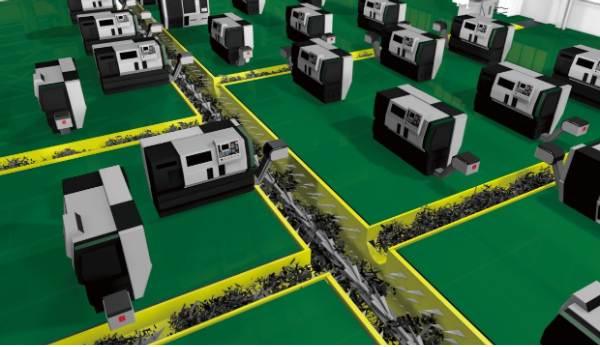

Green Intelligent Centralized Chip Conveyor and Filtration System

This system consists of three parts: centralized chip removal, centralized filtration, and chip processing. It enables automated operation in machining workshops, enhances production efficiency, maintains a clean working environment, and truly achieves the vision of an "intelligent and green factory." Centralized Chip Removal: This process collects and transports chips and contaminated liquids to subsequent processing systems. It forms an automated and intelligent connection with the main equipment, saving labor, reducing maintenance, and significantly improving on-site management standards. Centralized Filtration: Contaminated liquid is filtered to meet the user's required precision within this system. The clean liquid is then pumped into the pipeline network for machine tool use. The system operates stably with a low failure rate, greatly extending the service life of the cutting fluid, reducing waste liquid discharge, and contributing to energy conservation and environmental protection. Chip Processing: Chips transported via centralized removal are processed in this system. Through shredding, oil removal, and briquetting, chips are compressed into high-density blocks. This saves space, reduces transportation costs, and significantly improves chip recovery efficiency and commercial value.

Main products

Our main products consist of: Hinged belt chip conveyor -Compound chip conveyor -Permanent magnetic chip conveyor -Scraper and magnetic scraper chip conveyor -Drop-forged rivet less chain scraper chip conveyor -Screw chip conveyor -Paper band filter -Magnetic roller paper band filter -Integrated chip conveyor with filtering and cooling device -Vertical paper band filter -Vertical circulating filter -Vacuum circulating filter -Coolant central filtering system -Cyclone separator -Oil skimmer -Self-cleaning filter -High speed centrifuge -Single double shaft chip reducer and other functional parts.