Company Introduce

Shenzhen Helitai Technology Group Co., Ltd. is a professional CNC manufacturer integrating R & D, design, production and sales. Its product series are divided into crane five-axis linkage machining center, precision ceramic machining center machine, high-speed drilling and milling machining center machine, four-axis and five-axis polishing series, high-speed gantry machine, glass, ceramics and other high hard and brittle materials processing. R & D and production of automatic production lines for non-standard machines and industrial products. The company establishes the production base in Shenzhen bright newly developed area, the production base has the excellent mechanical processing manufacture equipment and more than 7000 square meters production workshops, simultaneously has established an outstanding research and development manufacture team which by senior skilled worker, senior engineer and so on the specialized talented person is composed, the time is grasping the technical development tendency and user's market demand, the research and development conforms to the customer demand new product, With advanced technology, scientific management, excellent quality, fast and thoughtful after-sales service, to provide customers with overall solutions and technical support, we will be reliable product quality, reasonable price, quality service to win the praise and trust of customers! The ultimate goal of Helitai is to meet customer needs, improve product quality, reduce production costs and improve production efficiency!

Exhibit brands

Exhibits

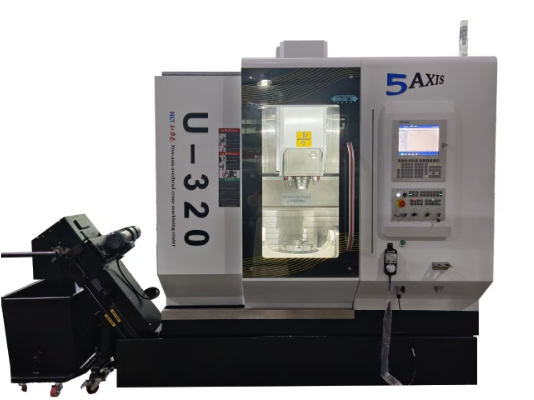

Crane type 5-axis machining center HLT-U320

Crane structure bed, to achieve outstanding rigidity, stability; The X, Y and Z linear axes are based on the movement of the base and the lathe bed, without the load of the worktable and the workpiece, and without the influence of the cutting operation environment, which can improve the low failure, long life, stable accuracy and unparalleled dynamic response of the machine tool. The AC axis rotary table is fixedly supported on the base lathe bed to avoid the precision error caused by the five-axis moving position; The AC axis selects the highest precision DDR five-axis turntable in China, while achieving high rigidity, high precision and high stability of the product. Crane type five-axis machining center is widely used in aerospace, automobile manufacturing, mold manufacturing and other fields. In the field of aerospace, the five-axis machining center can be used to process aircraft parts, such as engine blades, fuselage structures and so on. In the field of automobile manufacturing, it can be used to process automobile parts, such as engine block, crankshaft and so on. In the field of mold manufacturing, it can be used to process a variety of complex shapes of the mold.

Crane type 5-axis machining center HLT-U500

Core product advantages Super load and large stroke: fixed table design, no load limit, can process large parts that traditional machine tools can not accommodate. Excellent rigidity and stability: The crown block structure disperses the mass of the moving parts of the spindle onto the solid bridge. Compared with the moving column structure, the system rigidity between the workpiece and the tool is higher during machining, and the heavy cutting ability is extremely strong. High precision retention: the fixed worktable avoids the error accumulation caused by the movement of the workpiece, and the thermal deformation of the mineral casting/optimized structure is small, and the long-term precision is stable. Efficient "one-time clamping" processing: Five-axis linkage capability enables complete processing of complex parts, reduces repeated clamping, and greatly improves accuracy and efficiency. Advanced automation integration: The space on both sides of the workbench is wide, and it is easy to integrate the automatic exchange workbench system, on-machine measurement system, tool breakage detection and heavy tool library to create an unmanned intelligent production line. Excellent chip removal and accessibility: open structure, chips can fall directly into the chip groove below, and the operator can easily observe and approach the workpiece.

Ceramic carving machine

After years of ceramic processing technology, verification, combined with a variety of ceramic processing equipment, continuous improvement and optimization, we have developed a high-speed, high-precision ceramic engraving and milling machine with high cost performance for ceramic processing. In view of the stress of ceramic processing tools and workpieces, the machine tool has been improved in the aspects of bed structure, rigidity and dust protection, optimized the internal structure of the spindle, increased the power and torque of the spindle, increased the speed of the spindle, and improved the processing technology. It can realize high-speed heavy cutting, greatly improve processing efficiency, improve production capacity and save costs for customers.

Main products

Shenzhen Helitai Technology Group Co., Ltd. is a professional CNC manufacturer integrating R & D, design, production and sales. Its product series are divided into crane five-axis linkage machining center, precision ceramic machining center machine, high-speed drilling and milling machining center machine, four-axis and five-axis polishing series, high-speed gantry machine, glass, ceramics and other high hard and brittle materials processing. R & D and production of automatic production lines for non-standard machines and industrial products.