Company Introduce

Established in 2006, Shandong Nano Advanced Material Technology Co., Ltd. is a professional mineral casting production enterprise with complete intellectual property rights. It is in Jinan Mingshui Economic Development Zone. It covers an area of more than 6o acres and more than 150 employees,among them, there are 30 professional and technical personnel, The company is a modern enterprise integrating mineral composite material research, product design, mold design,manufacturing, product production and processing, and accessories assembly. East Star Precision Instrument Co., Ltd., which was established in 1989, is our brother company. We have the largest imported automatic mixing pouring equipment in the industry:the mixing capacity is 9 tons per hour. The molding equipment with exciting force of 70 tons, as well as large CNC, guideway grinder and other equipment that used for product and mold processing.

Exhibit brands

Exhibits

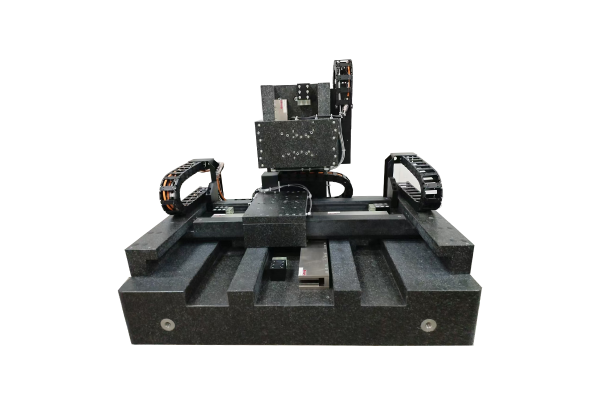

Granite air bearing parts

1. Product main material: natural granite (Indian stone) 2.Product size: 1100 * 1090 * 1410mm 3. Product use: Direct use of granite air guide rail, product integration X, Y, Z three-axis square box air bearing, with high precision, high stability, low maintenance costs and other characteristics. It is often used in semiconductor processing, semiconductor testing equipment and other precision equipment.

.png)

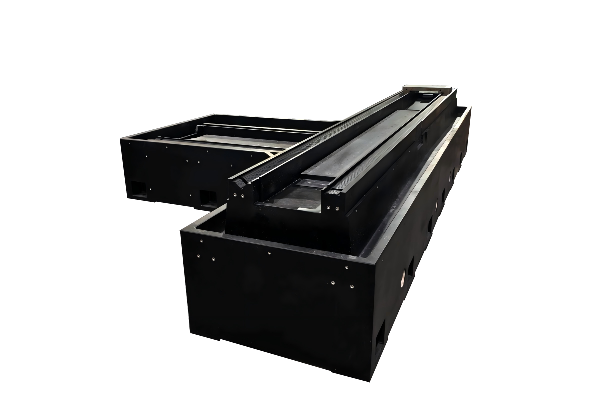

Mineral casting base with Hydrostatic guideway

1. Product material: Mineral casting base with Hydrostatic guideway 2.Product size: 2600 * 1500 * 700 mm 3. Product advantages: The bearing surface of the hydrostatic guideway is directly integrated by the mineral casting bed, and the hydrostatic module is directly combined with the mineral casting bed to replace the traditional wire gauge, and the straightness can be controlled at 0.5 μ/m, which further improves the accuracy and stability of the product.

Stute transforms mineral castings for bed frames

1.Product Material: Mineral casting 2. Product size :1800*1350*744mm 3. Product advantages: The mineral casting copy forming process is a manufacturing technology that uses high-precision molds to replicate complex geometric shapes. By directly replicating the geometric features of the master mold through the mold, it can produce complex curved surfaces, cavities or fine structures, with precision reaching the micrometer level. It is particularly suitable for the design of irregular shapes that are difficult to achieve with traditional metal processing. Combining the advantages of mineral casting materials, it is widely used in high-precision bed frames, precision instrument bases and other fields.

Granite measuring tools

Granite measuring tools have become the core equipment in the field of precision measurement due to the advantages of natural materials. Common types include granite flat plate, parallel rulers, square rulers, cubes, V-shaped blocks, etc., adapting to the needs of different measurement scenarios. Its core advantages are significant: natural granite has uniform texture, high hardness, small linear expansion coefficient, no internal stress, and can maintain accuracy for a long time; it is non-magnetic, avoiding the interference of magnetic fields on measurement accuracy, and is acid-alkali and corrosion resistant, and has a long service life. It is widely used in mechanical processing, precision manufacturing, metrological testing and other industries. It can be used as a key tool for workpiece detection benchmark, marking positioning, equipment installation and debugging, and provides reliable guarantee for high-precision production operations.

Main products

Granite Measuring Tools, Granite Testing Platform, Granite Components, Granite air bearing parts, Mineral Casting, Mineral Castings Bed Hydrostatic Guide, Mineral Castings Copy Forming Process Products, Mineral Filling Products