Company Introduce

JIATIE was founded in 1998. In 2002, JIATIE was acquired by the current Chairman Mr. Shaohua Tian, who established Kejie Machinery Automation Company Limited in 2004 and managed to enhance the brand value of JIATIE. We always remain true to our original aspiration of “Good Team, Good Product” and adhere to the principle of “advanced technology, scientific management, continual improvement, customer satisfaction”. We specialize in research and development, manufacture and marketing in machinery manufacturing industry. Today, JIATIE has evolved to become a High-tech Enterprise employing approx. 1000 staff and is also the drafting unit of national standards of high speed engraving and milling CNC machine.

Exhibit brands

Exhibits

JTDM-300 Compact Drilling and Milling Center

JTDM-300 drilling and milling center is a high-speed machine specially designed for small porous parts, which is independently developed and manufactured by Kejie Technology. Metal processing machine tools for milling, drilling, tapping and other processing fields are widely used in digital electronic products, automobiles and locomotives, Small and medium-sized boxes, covers and plates in the industries of instrumentation, light industry and textile, electronics and electrical appliances, aerospace and machinery manufacturing, etc. Processing of shell, disk and other parts. JTDM-300 has the characteristics of rapid milling, drilling and tapping, especially the processing effect of milling is particularly prominent; The system is powerful, stable and reliable, and has a more user-friendly control interface. The appearance of the machine tool is beautiful, the overall layout is reasonable, the design is humanized, and it inherits the consistent excellence of the "JIATIE" brand Good quality, the use of high-quality parts and high standards of manufacturing, thus ensuring the high stability of the machine, high reliability, for your Efficient production escort. At present, this type of product has been widely used in mobile phone or tablet shell, hard disk accessories, High-precision spare parts and other fields, such as: major well-known brands of mobile phones, tablet computer CNC processing, world-renowned brands Server hard disk accessories processing.

BJ-0267 X1 右侧.png)

KUPI-X1 Ultra Precision Vertical Machining Center

X1 is an ultra-precision vertical machining center with wall-mounted gantry structure. It uses high-speed digital control system, embedded electric spindle with cash, lightweight steel structure and highly responsive transmission mode to achieve the highest productivity for users. This machine adopts the special technology of combining high-quality cast iron with advanced mineral casting to construct the matrix, which has both rigidity and shock absorption, and the whole machine is equipped with precise cooling circulation pipeline, which has strong ability to maintain accuracy for a long time.

.png)

JTMA-400 High Speed 5-axis Machining Center

Features: - Gantry-structure type makes better machine dynamic performance and accuracy retention - Equip with DD direct drive 5-axis rotary table - Moving component and machining area are fully isolated, machine cleaning is convenient - Reasonable and excellent human-machine interaction design, ensures the operation is comfortable and convenient - 5-axis rotary centers automatic setting of automatic wireless probe (optional) - Equip with full-closed loop control technology, more accurate and reliable machining performance - High-accuracy, high-speed and high-efficiency machining ability - Excellent human-machine interaction interface Machining materials: Aluminum alloy, copper and steel Application industries: Mold, precise component part, etc

JTDR-400 5-axis Drilling And Milling Center

Features: - High-speed tool change system, quick tool change time - DD direct drive high-speed rotary table, accurate and reliable positioning ensures machining performance - High moving speed, reduces non-cutting time - High-speed and high-efficiency machining ability, it is the extremely good choice of mass production - Advanced famous brand CNC system, powerful and reliable - Favorable human-machine interaction interface, simple operation Machining materials: Carbon steel, steel alloy, copper, aluminum alloy and composite material (plastic) Application industries: The component machining of the medium-and-small-size box, lid, plate, shell, disk, etc for the industries of 3C product, automotive, instruments and apparatus, light industry and textile, electric component, aviation and aerospace, machine manufacturing,etc

JTDR-550 5-axis machining center

Equipment overview: JTDR-550 high-precision five-axis machining center is independently developed and manufactured by Kejie Company. It is used for small and medium-sized parts processing machine tools with five-axis turntable, which can complete one-time clamping multi-surface processing, high-speed and high-torque DD direct drive turntable, and rapid positioning processing. It can be widely used in small and medium-sized parts and various precision mold processing in the fields of automobile accessories, aerospace, 3C products, communications and so on. Equipment features: High rigidity main body structure, with higher precision and stability Equipped with high torque DD direct-drive turntable, high precision, fast positioning, short processing auxiliary time, high rigidity interface spindle, to achieve higher cutting performance and processing surface quality Fully enclosed compact external protection design, closer operating distance, greatly improve the convenience of operation, tool arm-type tool magazine, can load a large number of tools, tool change speed. Inclined surface design of processing cavity, more direct discharge of cutting waste chips, reduce accumulation, and reduce the frequency of cleaning and maintenance in the machine Excellent human-computer interaction interface, easy to operate Independent research and development of CNC system, powerful and reliable

JTDR-160 special medical plane

Dental special machine

JTGK-700S graphite machine

Equipment overview: JTGK-700S graphite engraving and milling machine is a high-speed, high-precision CNC machine tool for dry-cutting graphite processing under the brand of Guangdong Kejie JATIE. This model inherits the excellent contour accuracy and surface quality of Jiatie engraving and milling machine when processing complex curved surfaces. The new structural design further improves its dynamic cutting performance and ensures that the processing dimensional accuracy and surface effect are more ideal. It is an ideal model for processing high-end graphite electrodes and their parts. Equipment features: It is mainly suitable for dry cutting processing of graphite and other products. The design of box-type foundation structure and the unique damping characteristics make the machine tool have more excellent dynamic processing performance, fully enclosed protection and equipped with professional dust collector, effectively reduce the leakage of dust and ensure good dust removal. Effect The shaft motion system adopts special protective measures to ensure the service life of moving parts. Multi-function optional, suitable for different levels of demand Spiral chip conveyor and cleaning and blowing at the corners of the machine bed are equipped as standard to reduce the difficulty of machine cleaning.

JTGK-600G PRO High Precision CNC High Speed Machine

Equipment overview Machine tool structure: JTGK-600G pr0 is a high speed machine with wall gantry structure, using high speed digital control system, with advanced embedded electric spindle, with vertical processing structure, to achieve the highest productivity for users. Features of the machine tool structure: the machine adopts the moving structure of the worktable. The base structure is made of high-quality cast iron, which has both rigidity and shock absorption, strong ability to maintain accuracy for a long time and good surface shape. Moving parts are analyzed by FEM finite element structure, which makes the overall rigidity of the machine tool more balanced, and the performance of processing circular arc and curved surface is better. The whole machine structure with high rigidity and high damping brings better dynamic stability, and improves the vibration suppression ability and tool life. While improving the cutting ability, the surface roughness and micro-feature response ability are guaranteed. Spindle features: This machine adopts Jiatie self-developed high-speed embedded electric spindle, and the spindle interface adopts HSK50a with clamping position, high rigidity and high speed interface. By improving the structural accuracy of the electric spindle, the spindle has the characteristics of high rigidity and low vibration. Optimize the spindle motor structure, provide greater spindle torque and real-time response capability, greatly improve the stability of the tool tip, so that the spindle can maintain stable output during large cutting, and improve the surface roughness of processing. The spindle is suitable for high-speed milling of various ferrous metals and non-ferrous metals. Tool magazine structure: This machine can select the chain type tool magazine structure, and the tool can be exchanged between the spindle and the tool magazine through the rotating arm. The tool magazine jaws are made of high-strength materials, which can withstand the amount of access and improve the stability of the operation of the tool magazine. The rotating arm is controlled by a servo motor, which can carry out high-precision positioning and reduce the collision damage of the tool handle. Numerical control system: a new generation of numerical control technology is used, equipped with advanced computing power and high-speed high-precision algorithm, which greatly improves the data processing capacity and motion control performance of the numerical control system. Support full closed-loop system and on-machine measurement system, solve the quality problems caused by workpiece deformation, improve the production yield, and make the processing accuracy more stable. Equipment features Processing range: suitable for the processing of high hardness materials such as hardened steel, die steel, etc., applied to the processing of dies and parts products, mainly applied to the processing field of integrated processing of rough and fine dies and deep cavity processing. Humanized interaction: The protection design of the machine tool is compact. The cooling machine and the cutting fluid tank are all contained in the sheet metal. The square shape makes it easier to plan space. The front of the machine tool can display the current key status of the machine tool, which is convenient for workers to operate. The parts and assembly quality of the machine tool shall meet the technical requirements of the drawing. Its safety standards are in line with national standards.

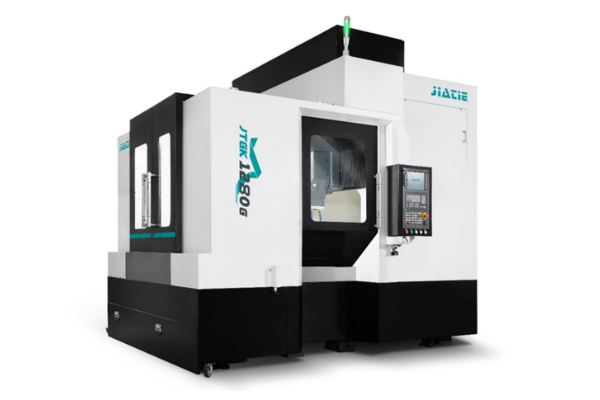

JTGK-800 GPRO High Precision CNC High Speed Machine

JTGK-800G pro CNC high-speed machine is an efficient and high-precision CNC machine newly developed and designed by Kejie Technology. The machine tool adopts a number of new technologies, so that the machine tool has excellent dynamic processing performance and high rigidity, and the processing quality is stable. Shit. The machine adopts an integrated overall design, has an excellent human-computer interaction interface, and the machine tool control is more humanized. Suitable for copper, aluminum, steel, stainless steel and other materials processing, mainly used in high precision molds and precision parts products. Processing.

JTGK-1280G CNC high-speed machine

JTGK-1280G CNC high-speed machine is a professional high-speed machine of JIATIE brand with advanced CNC technology and brand-new mechanical structure. It uses the unique design and assembly process of Jiatie Company, has outstanding dynamic processing performance, and has efficient and high-precision milling processing capacity. It is your ideal model for processing large-size molds and products in batches. JTGK-1280G CNC high speed milling machine adopts precision linear slide and screw rod assembly design to ensure its excellent high speed and high precision milling performance according to the demand characteristics of metal parts and moulds.

Main products

We provide products for various industries of electronic communications, medical precision instrument, automobile manufacturing, railway transportation, equipment manufacturing, precision mold machining, etc. The products are CNC controller, high speed engraving and milling CNC machine, CNC machine for specular chamfering, glass machining center, drilling and milling center, graphite machining center, PCB drilling machine, loading and unloading material manipulator, LED wire bonding machine, automated production line, build-up of intelligent production data center, etc.