Company Introduce

Introduction of Meidehan Technology Dongguan Co., Ltd. Established in 2021, Medehan Science and Technology Dongguan Co., Ltd. is an innovative enterprise focusing on the research, development, production and sales of core functional components of high-end machine tools, with four-axis turntable, five-axis turntable, intelligent probe and precision tool setting instrument as the core product line, providing customers with "multi-axis linkage processing + precision detection control". Help the manufacturing industry to achieve efficient and high-precision production upgrade. Since its establishment, the company has focused on the technological breakthroughs and localization of the core components of industrial mother machines, built a research and development team led by senior engineers in the industry, and integrated servo drive, high-precision positioning, intelligent sensing and other core technologies into product design. Core product line coverage: -Four-axis/five-axis turntable: It adopts direct-drive motor and high-precision self-backlash structure, and is equipped with servo drive and grating feedback system. It has the advantages of high rigidity, low backlash and fast response. The repeated positioning accuracy reaches second level. It is suitable for 3-axis to 5-axis machining centers. It can realize multi-surface processing of complex workpieces by clamping at one time, and greatly improve production efficiency and processing consistency; -Precision probe: covering infrared, radio and wired series, with probe trigger repetition accuracy ≤ 1μm and protection grade up to IP67, which can resist the interference of harsh processing environment such as coolant and scrap iron, and realize workpiece alignment, online size detection and error feedback; -Intelligent tool setting instrument: non-contact laser precise measurement, tool length, tool diameter, tool swing, broken tool detection,

Exhibit brands

Exhibits

ROP40 probe

1. Micron precision: high-precision trigger sensing technology is adopted, the repeated measurement precision reaches micron level, the size deviation of molds and precision parts is accurately captured, and the processing quality is more controllable. 2. Multi-scenario adaptation: Perfectly compatible with 3-axis/5-axis machining centers and turning-milling composite machine tools, covering the processing and testing needs of mold manufacturing, new energy automotive parts, aerospace precision parts and other industries. 3. Strong anti-interference: infrared modulation transmission technology, no fear of machine tool processing coolant, scrap iron, vibration and other harsh environments, signal stability without interruption. 4. Intelligent linkage: It can be seamlessly connected with the CNC system of the machine tool, realize the automation of workpiece alignment, online measurement and error compensation, reduce manual intervention, and improve the processing efficiency by more than 30%.

TOP400 probe

1. Sub-micron measurement accuracy: The one-way trigger repetition accuracy of the measuring needle reaches 0.25 μm 2σ, which can accurately capture the fine size deviation of complex curved surfaces and precision cavities, meet the strict processing tolerance requirements, and greatly improve the one-time processing yield of workpieces; 2. Anti-interference wireless transmission: With FHSS hybrid frequency hopping technology, the transmission distance of 2.4G wireless communication can reach 15 m, effectively avoiding electromagnetic interference and transmission dead angle in the workshop, stable signal transmission without delay, adapting to large machine tools and complex production environment; 3. Industrial-grade solid protection: It adopts 304 stainless steel integrated shell and fully sealed structure design, with protection grade up to IP67, which can resist coolant scouring, scrap iron erosion and dust pollution, and can operate stably for a long time in a wide temperature environment of -40 ℃ ~ 85 ℃; 4. Low trigger force protection design: the trigger force in XY direction is as low as 0.1 N, and the trigger force in Z direction is only 0.8 N, which can avoid surface damage and deformation when detecting soft materials or fine workpieces, and meet the measurement requirements of 3D complex shape workpieces; 5. Long-lasting endurance and adaptability: The built-in large-capacity lithium sub-battery can support 2000 hours of continuous work on a single charge. With low-power sleep mode, it can meet 24-hour uninterrupted production. The diameter of the product is only 40mm, and the volume is compact. It can adapt to small and medium-sized machining centers, turning and milling machines and other equipment.

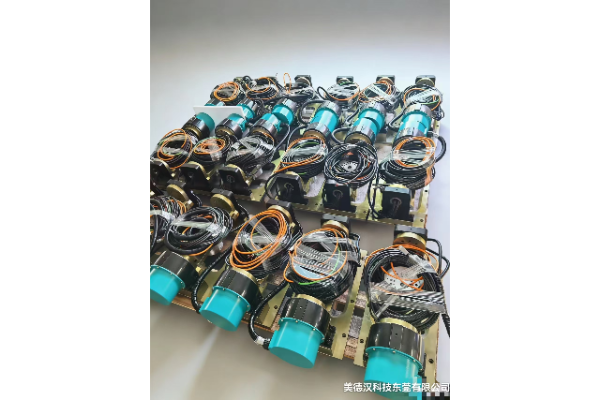

Four-axis turntable

1. Second-level precise positioning: equipped with high-precision absolute encoder and full closed-loop control, the positioning accuracy is ≤ ± 3 ″, the repeated positioning accuracy is ≤ ± 1 ″, and the axial and radial runouts of the disk surface are controlled within 0.005 mm to ensure the dimensional consistency of multi-process processing. 2. High-rigidity and heavy-load design: The body is made of high-strength cast iron, and the internal stress is eliminated by aging treatment. With the innovative clamping structure and heavy-load guide rail, the clamping rigidity is three times higher than traditional design. The maximum bearing capacity can reach 500 kg, and there is no micro-deformation under heavy cutting conditions. 3. High-speed and efficient operation: torque motor direct-drive transmission, abandon the traditional worm gear clearance, the maximum speed can reach 250 rpm, the locking time of adjacent stations is as short as 0.3 seconds, and the processing cycle of complex workpieces is shortened by more than 40%. 4. Stable protection under all working conditions: The fully sealed structure with IP67 protection grade can resist coolant scouring, scrap iron erosion and dust pollution. It can operate continuously in a wide temperature environment of -40 ℃ ~ 85 ℃. The maintenance cycle is up to 8000 hours. The transmission has zero wear and is free of regular maintenance. 5. Flexible adaptation features: compatible with mainstream CNC systems such as SIEMENS, Fanuc, Mitsubishi, etc., the diameter of the disk surface covers 200-1500 mm, supports modular customization, can be quickly integrated into various machining centers, and adapts to the processing requirements from small precision parts to large heavy-duty workpieces. The core value of exhibits -Replace the traditional multiple clamping process, reduce the positioning error and auxiliary time, and improve the product qualification rate to more than 99.5%; -The four-axis function of the machine tool can be upgraded without complex transformation, which greatly reduces the purchase cost of high-end processing equipment. With centralized lubrication system and intelligent self-check module, real-time feedback of operation status, convenient and efficient operation and maintenance.

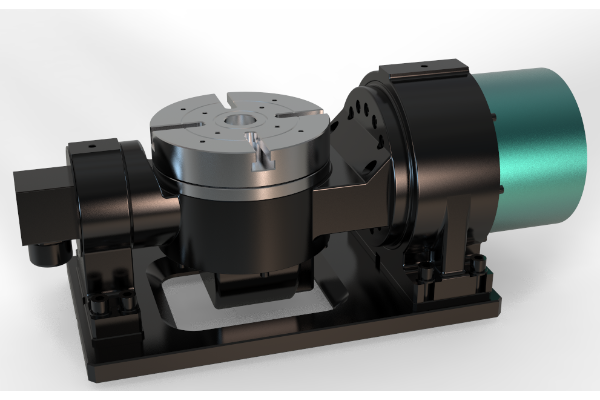

Five-axis turntable

1. Micron precision positioning: equipped with high-precision grating encoder and full closed-loop control algorithm, the repeated positioning accuracy is as low as ± 1 arc second, and the indexing accuracy is up to ± 3 arc second. The dynamic error compensation technology can correct the thermal deformation and load deviation in real time to ensure that the processing tolerance of complex workpieces is controlled within 0.005 mm. 2. High-rigidity and heavy-load design: The machine bed is made of high-strength cast iron, and the internal stress is eliminated by aging treatment. With the dual-drive anti-backlash structure and heavy-load guide rail, the maximum bearing capacity can reach 850 kg, which can maintain structural stability even under heavy cutting conditions and avoid micro-deformation affecting the processing quality. 3. High-speed dynamic response: The brushless direct-drive motor and parallel transmission structure are integrated, the traditional gear transmission clearance is abandoned, the angular acceleration is increased by 50%, the maximum speed of the turntable can reach 300r/min, the locking time of adjacent stations is as short as 0.3 seconds, and the processing cycle of complex workpieces is shortened by 30% -50%. 4. Stable protection under all working conditions: It adopts a fully sealed structure design with a protection grade of IP67, which can resist coolant scouring, iron erosion and dust pollution. It can operate continuously in a wide temperature environment of -40 ℃ ~ 85 ℃, with a precision attenuation rate of ≤ 0.001 mm and a maintenance cycle of 8000 hours. 5. Intelligent adaptation features: Built-in AI working condition monitoring module, real-time acquisition of 18 key data such as speed, temperature, load, etc., supports predictive maintenance; compatible with mainstream CNC systems such as SIEMENS, Fanuc, Mitsubishi, etc., can be quickly integrated without complex debugging, and adapts to 3-axis to 5-axis machining centers.

Wireless probe P300

Ultra-precision measurement: the one-way trigger repeatability of the measuring needle is ≤ 1 μm, which can capture the fine size deviation of the mold cavity and precision parts, and ensure that the processing tolerance is controlled within the strict industrial standard; 2. Wireless efficient transmission: equipped with 2.4G wireless communication module, the transmission distance can reach 30 m, the anti-interference ability is strong, there is no fear of coolant, scrap iron, electromagnetic interference in the workshop, and the signal transmission is stable without delay; 3. High protection level: stainless steel shell + sealed structure design, protection level up to IP67, long-term stable operation in the harsh processing environment of coolant scouring and dust pollution; 4. Miniaturization design: The product is compact in size, with a diameter of only 30 mm and light in weight. It can be installed on small machining centers, precision engraving and milling machines and other machine tools with limited space, and has strong adaptability; 5. Long endurance operation: Built-in large-capacity lithium battery, single charge can support 2000 hours of continuous work, with low-power sleep mode, to meet the factory's 24-hour uninterrupted production needs.

Tool setting instrument

MH laser tool setting instrument is a high-precision tool measuring equipment based on laser detection technology. It is specially designed for CNC machining centers, milling machines, lathes and other machine tools. It can realize non-contact rapid measurement of tool length and diameter, as well as real-time detection of tool wear and breakage, effectively improve processing accuracy and production efficiency, and reduce the scrap rate caused by tool problems. Core features 1. Non-contact measurement: The principle of laser detection is adopted, which does not require physical contact with the tool, avoids the wear of the tool and the detection parts, prolongs the service life of the equipment, and is suitable for the measurement of ultra-fine, super-hard and other vulnerable tools. 2. High-precision detection: The laser measurement accuracy can reach μm level, and the repeated positioning accuracy is ≤ 0.001mm, which can accurately capture the fine size changes of the tool and meet the measurement requirements of precision processing. 3. Quick response: The detection response time is less than 1ms, and the tool parameter detection can be completed in the machining gap of the machine tool, which does not take up additional production time and improves the operation efficiency of the production line. 4. Solid and durable structure: The whole body is made of high-rigidity aluminum alloy, which is treated by hard anodizing to resist impact and vibration, and adapt to the harsh environment of machine tool processing; the sealed design effectively prevents dust and cutting fluid erosion, and ensures long-term stable operation. 5. Convenient installation and adaptation: Modular structure design, can be directly installed on the machine table or beside the tool magazine, compatible with Fanuc, Siemens, Mitsubishi and other mainstream CNC systems, support manual/automatic mode switching. 6. Intelligent alarm function: When the tool wear is detected to be out of tolerance, damaged or missing, the equipment will send an alarm signal to the CNC system in real time, and the machine tool can automatically stop or switch the spare tool to avoid the generation of defective products in batches.

Main products

Meidehan Technology Dongguan Co., Ltd. focuses on the R & D and manufacturing of core functional components of machine tools, with four-axis turntable, five-axis turntable and precision probe as the core product line, providing "multi-axis linkage + precision detection" as an integrated solution for high-end manufacturing, adapting to the precision processing needs of mold manufacturing, aerospace, new energy vehicles, medical equipment and other industries.