Company Introduce

Established in 1937, Makino Machine Tool is the first machine tool manufacturer in Japan to produce CNC milling machines and machining centers. In 2002, a factory was set up in Kunshan, as the Group's core base of electric machining machine tools, which can research and develop machine tool application software and customized products, and provide technical consultation and maintenance services; in 2019, the factory in Wuhan will be completed, mainly operating vertical/horizontal machining centers, covering the processing needs of various fields, and providing solutions such as automation integration. Muye China integrates R & D, manufacturing, sales, technical consultation and after-sales service to help domestic manufacturing enterprises improve quality and efficiency.

Exhibit brands

Exhibits

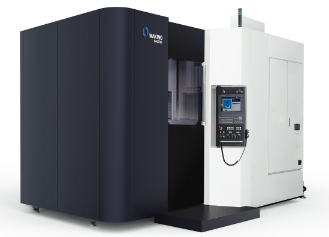

High Performance 5-Axis Vertical Machining Center DA500

Makino DA500 machine tool is a high-performance 5-axis vertical machining center, designed to improve the productivity and accuracy of parts processing, which can achieve agile feed axis movement and efficient processing. Processing advantages 1 Efficient machining: Makino DA500 can significantly reduce various non-cutting time, including spindle acceleration, positioning, tool change, tool breakage detection and pallet change time, thus improving the overall machining efficiency. 2. High-precision machining: By using advanced control technology and high-precision sensors, the machine tool can achieve micron-level machining accuracy and meet the machining requirements of high-precision parts. 3 Flexibility: The machine tool is equipped with a wealth of optional specifications and equipment, which can be customized according to the specific needs of customers, such as pallet magazine specifications, turntable functions, etc., to enhance the flexibility and adaptability of processing. Field of application Makino DA500 machine tool is widely used in semiconductor equipment, medical, aerospace, automotive parts and other high-precision, high-efficiency processing fields. Its excellent processing performance and flexibility enable the machine to meet the processing needs of complex parts and improve production efficiency and product quality. In addition, the machine tool is also suitable for occasions requiring rapid production change and processing of various workpiece sizes, which is helpful for enterprises to improve overall production efficiency and competitiveness.

High Precision Vertical Machining Center iQ300

The unique mirror solution can greatly improve the processing accuracy and surface quality, and effectively reduce the grinding process after processing. The tool can be ground multiple times for reprocessing, thus reducing the total production cost; the 45k spindle, three-axis linear motor design, can achieve machine tool sub-micron precision machining through the Pro6 system; special thermal stabilization equipment and functions can ensure the stability of the machine tool during long-term operation, and the tool tip can be stabilized within 1 μm at full load 45k speed for up to 12 hours.

High precision EDM machine EDAF2i ULTRA

EDAF2i ULTRA is the latest high-precision CNC EDM machine tool launched by Makino Machine Tool. It uses Makino's newly developed micro-EDM control circuit and marble worktable to release powerful machining performance and improve the quality and efficiency of EDM surface to a new height. Processing advantages: Vdi grain surface uniformity, connector corner clearing and melting, electrode loss control, processing efficiency, etc. Applications: ultra-precision connector industry, medical industry, IC packaging industry and other industries with higher requirements for EDM

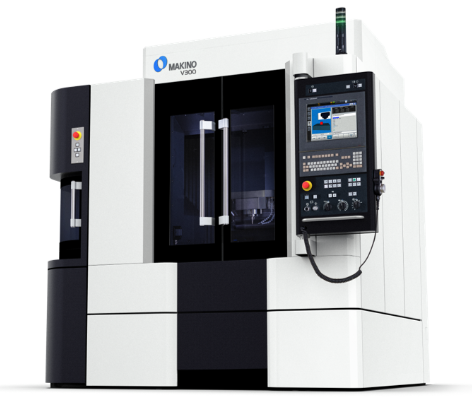

Advanced Vertical Machining Center V300

Makino V300 machine tool is an advanced vertical machining center, designed for users who pursue high precision and high quality machining. The machine combines the classic advanced technology and innovative ideas of Makino V33i, aiming to provide users with stable and efficient processing solutions. Processing advantages: High precision machining: Makino V300 machine tool adopts advanced control system and precise mechanical structure to ensure high precision and stability in the machining process. Whether it is a complex surface or a small detail, it can get perfect processing effect. Field of application: Makino V300 machine tool is widely used in precision mold manufacturing and high-precision fixture industry, and its excellent thermal stability can effectively meet the needs of high-precision complex processing.

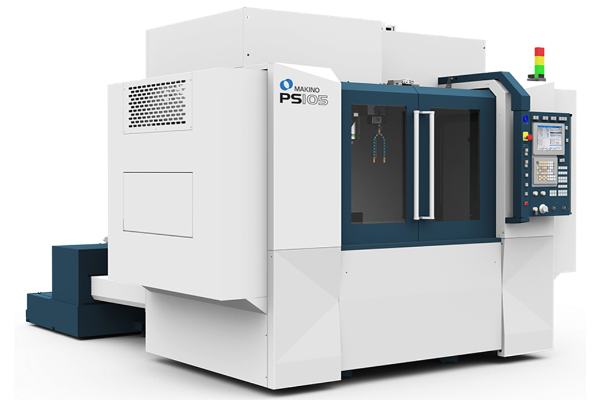

Vertical machining center PS105

"The PS series uses Makino's high-performance spindle technology to ensure high material removal rate while ensuring the required surface quality and accuracy.". The mechanical structure of the linear guideway guarantees the sensitivity, stability, rigidity and precise movement of the machine tool even when it is subjected to the maximum load. It is mainly aimed at multi-variety, small batch parts production and precision metal processing industries. Such as: aerospace, medical, automotive, general engineering and precision parts and other fields to provide users with the required performance. "

High precision oil base line cutting machine UPV-3

UPV machine tool is a high-precision oil baseline cutting machine tool produced by Makino Machine Tool Company, which is widely used in the field of ultra-fine machining. Known for its superior machining accuracy and surface finish, the machine is capable of cutting with a minimum wire diameter of 0.05 mm and maintaining the optimum finish of Ra 0.05 μm. UPV machine tools play an important role in many industries, including IC packaging industry, lithium battery tab mold industry, precision connector industry and high-precision mold blank industry of powder metallurgy mold. In the IC packaging industry, the UPV machine can ensure the cavity accuracy and surface finish of the die for the chip lead frame, thereby improving the packaging quality. In the manufacture of lithium battery tab mold, its high precision and stability ensure the performance and safety of the battery. For precision connectors, the high precision and high finish capabilities of the UPV machine ensure connection reliability and signal transmission quality. In addition, the high rigidity and stability of UPV machine tool can effectively improve the dimensional accuracy and consistency of the die blank in the manufacture of powder metallurgy die, thus improving the quality of the final product. In a word, UPV machine tools, with its advanced technology and excellent performance, provide reliable solutions for high-precision machining needs in various industries.

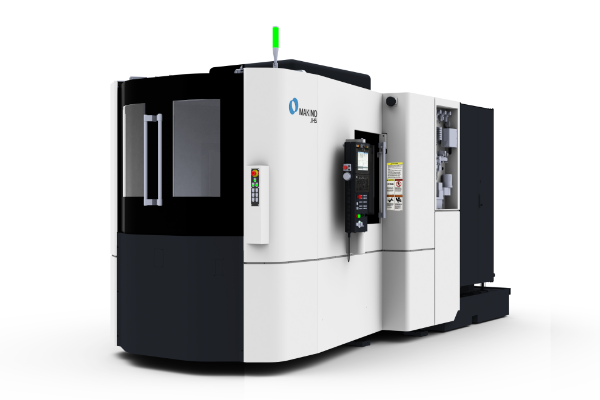

Double Exchange Table Horizontal Machining Center JH5

JH5, a domestic horizontal machining center with double exchange worktables, continues the consistent core advantages of Muye equipment, deeply integrates the three characteristics of "high rigidity, high stability and high durability" into the product gene, provides core support for enterprises in the market competition of multi-varieties and fast delivery, and helps parts manufacturing enterprises to cope with the production challenges of rapid changes in the market. JH5 is suitable for a variety of processing scenarios, which can not only be suitable for mass production scenarios, meet the large-scale processing needs of parts suppliers, but also for complex parts processing tasks in the field of general engineering machinery processing.

Main products

Specializing in the manufacture of CNC metal processing machine tools and provide flexible processing innovation solutions in the automotive, aviation and mold processing industries.