Company Introduce

Whellong Machine Tool (Guangdong) Co., Ltd. is headquartered in Hongmei Town, a water township area at the junction of Dongguan and Guangzhou in the core region of the Guangdong-Hong Kong-Macao Greater Bay Area, where its R&D and production base is also located. The company has established an Application Technology Center in Shanghai to serve nationwide business and a R&D Design Center in Xi'an, Shaanxi Province. Inspired by Swiss technological expertise and benchmarking its quality against Japanese standards, the company leverages the cost-effectiveness of Chinese manufacturing while prioritizing technological application. Its goal is to build a globally influential R&D-driven Chinese machine tool brand targeting international markets, achieving import substitution. As a provider of precision and ultra-precision turning and grinding equipment as well as automated production cells, it aims to deliver cutting-edge solutions to global customers.

Exhibit brands

Exhibits

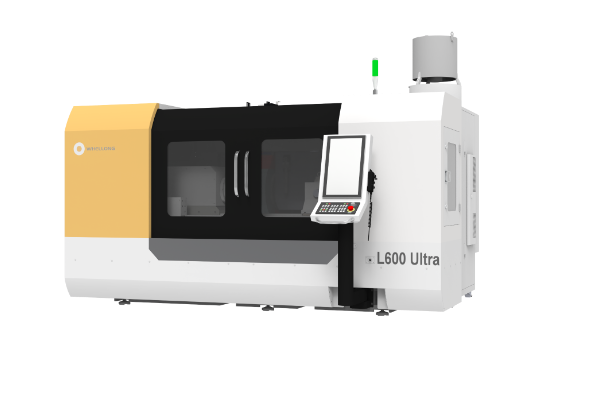

L600 precision cylindrical grinding machine

The L600 high precision CNC cylindrical grinding machine is an ideal high precision cylindrical grinding machine platform for small and medium-sized parts processing. It can be equipped with a single grinding wheel straight cut or beveled cylindrical grinding head, or equipped with a CNC rotary B-axis directly driven by a torque motor. It can be specially designed according to the needs of users. Every production link of the machine tool is strictly in accordance with the highest manufacturing standards. The machine tool has rich configuration and wide application range; the strict manufacturing process ensures its excellent performance and stable quality; the SIEMENS grinding software is adopted, which is convenient for programming and operation and easy to use; the high rigidity bed and structure are suitable for the production requirements from single piece to mass production.

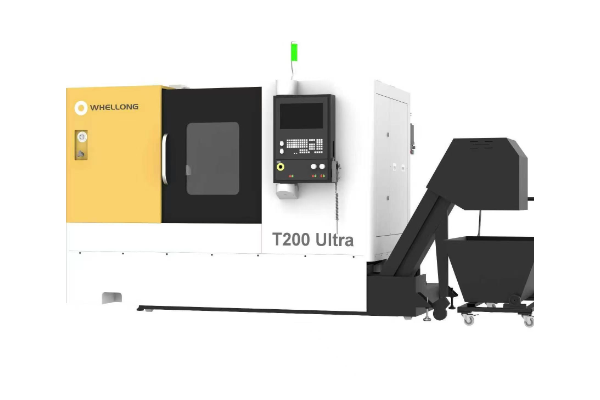

T200 Turning Center

High accuracy-Stable static and dynamic accuracy X/Z axis full travel positioning accuracy 0.008 (ISO 230-2) X/Z axis full travel repeat positioning accuracy 0.004 (ISO 230-2). Designed, manufactured and tested in full compliance with IS0230-2 2006 Turning Center Qualification Standard. All structures and castings are designed with the unique reverse finite element analysis method to ensure that all machine tool products have more scientific structural rigidity and structural rationality. The core components (screw nut, screw bearing seat, driving motor seat, lathe bed and spindle) support the selection of oil cooling system and adopt multi-loop temperature control design. Centralized management and control by the external oil cooler can reduce the vibration of the machine tool while effectively inhibiting thermal deformation and ensuring the processing stability. Expand the configuration of cutting fluid cooling machine, realize the constant temperature control of cutting fluid, and further improve the processing effect.

Main products

As a provider of precision and ultra-precision turning and grinding equipment as well as automated production cells。