Company Introduce

Dongguan Evermi CNC Equipment Technology Co., Ltd. is a high-tech enterprise with high-end CNC machine tools as its main business, which integrates R & D, production, sales and service. The company adheres to the enterprise mission of "making high-end five-axis universal" and the enterprise value of "serving customers wholeheartedly". It is committed to focusing on the product development and application technology research of five-axis linkage machining center as the core, realizing the import substitution of high-end five-axis equipment, and providing efficient processing solutions based on five-axis linkage CNC machine tools for domestic aerospace, automotive, medical, mould, precision parts processing and other fields.

Exhibit brands

Exhibits

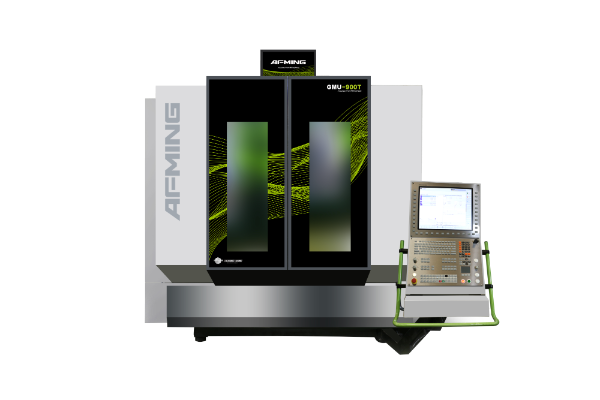

GMU-900T 5-axis machining center

GMU-900T 5-axis milling and turning center: 1. High rigidity: It is equipped with a crown block gantry frame, and the ribs are arranged reasonably to ensure that there is no vibration during milling and turning. The C-axis uses a high-torque automotive torque motor to ensure the smooth and powerful rotation of the workpiece in the turning mode. 2, high precision: A/C cradle table with patented gear backlash technology, no reverse clearance during processing, angle control to 0.001 °. Milling as the main, synchronous auxiliary turning process of the same clamping continuous processing, to avoid multiple positioning errors, precision life can reach several years. 3, high efficiency: equipped with 15000 rpm turn-milling composite electric spindle, standard 48 T tool magazine 12 seconds fast tool change, with automatic chip removal system, reduce non-processing time. Technical parameters: 1. Accuracy performance: X/Y/Z axis positioning accuracy: 0.008/0.008/0.007mm, repeated positioning accuracy: 0.005/0.005/0.004mm; A/C axis positioning accuracy: 8 arc seconds, repeated positioning accuracy: 5 arc seconds. 2. Speed performance: X/Y/Z axis fast displacement up to 40/40/40m/min, maximum cutting feed rate 20m/min, A/C axis fast feed speed 20/600rpm.

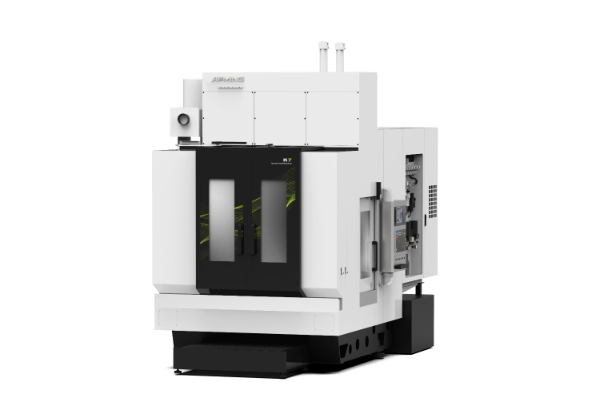

K7 horizontal five-axis machining center

1. K7 is of moving-column structure and equipped with high dynamic response drive lightweight design. X/Y/Z axes are of high response ball screw drive. The left and right feed acceleration of X axis is 1G, the upper and lower feed acceleration of Y axis is 1G, and the ram feed acceleration of Z axis is 1.5g. The workpiece is clamped at one time to realize multi-sided milling, which greatly shortens the in-process time. It is especially suitable for multi-face and five-axis high-speed and high-efficiency processing of complex parts of die-cast aluminum automobiles. II. Technical parameters: 2. Accuracy performance: X/Y/Z axis positioning accuracy is 0.008/0.008/0.008 mm, and repeated positioning accuracy is 0.006/0.006/0.006 mm; A/C axis positioning accuracy is 12 arc seconds, and repeated positioning accuracy is 8 arc seconds, which meets the processing requirements of precision parts. 3. Speed performance: rapid displacement of X/Y/Z axis reaches 75/75/75m/min. The maximum cutting feed rate is 50m/min, and the fast feed speed of A/B axis is 50/75rpm. Combined with the efficient tool change system, the processing efficiency is greatly improved.

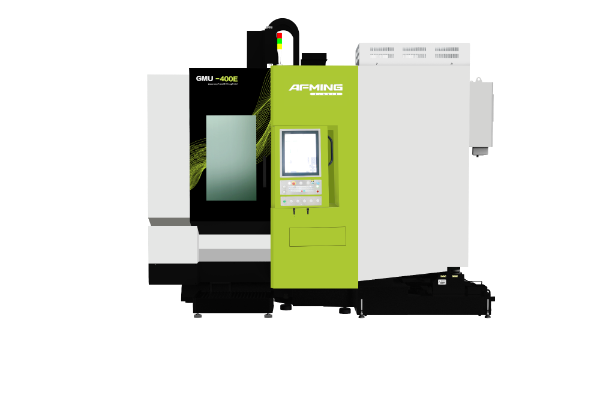

GMU-400E

The best matching of stiffness, damping and mass of the whole machine is realized by using fixed beam gantry structure and FEA dynamic optimization technology, together with double-gear anti-backlash transmission. X/Y/Z axis stroke 550/600/400 mm, A/C axis rotation range ± 120 °/360 °, equipment spindle speed 15000 rpm, with 40T tool change system, tool change time is only 2.5 s, can efficiently complete the complex curved surface multi-surface processing, significantly shorten the production cycle. It is suitable for processing small moulds, auto parts, precision parts and aviation parts. Technical parameters: 4. Accuracy performance: X/Y/Z axis positioning accuracy is 0.005/0.005/0.005mm, and repeated positioning accuracy is 0.003/0.003/0.003mm; A/C axis positioning accuracy is 6 arc seconds, and repeated positioning accuracy is 4 arc seconds, which meets the processing requirements of precision parts. Speed performance: X/Y/Z axis fast displacement up to 30/30/30 m/min. Maximum cutting feed rate 10m/min, A/C axis fast feed speed 20/30 rpm, combined with efficient tool change system, greatly improve the processing efficiency

DMU400 five-axis linkage machining center

DMU-400 X/Y/Z stroke: 586/370/350mm Distance from spindle face to table: +110 to -5 (-20 tool Angle) /360 infinity Table size: 400mm Maximum load: 100kg X/Y/Z fast displacement: 40/40/40m/min Maximum cutting feed rate: 20m/min Machine size: 3010X2040X2800

Main products

Five-axis CNC machine tool, gantry high-speed machining center, slider grinder, high-speed graphite machining center and core parts