Company Introduce

Yongju Precision Technology Co., Ltd. is composed of a group of experienced machine tool design and production teams who love R & D and challenges, specializing in the production of CNC door-type integrated machining centers. Wing Ju Precision Technology Co., Ltd. firmly believes that only "perpetual" operation can make a "great" business. Adhering to FOUR-STAR's enterprise spirit of excellence, trust, wisdom and service, To provide customers with a full range of door-type machine tool products. FOUR-STAR stands for excellence, trust, wisdom and service, and provides customers with diversified, humanized and optimized products and services with the attitude that the relative existence of enterprises comes from the absolute satisfaction of customers. The company combines the experience and technology of Japanese high-quality companies, successfully develops various types of large-scale ultra-high speed and ultra-precision gantry machining center machines, provides customers with a full range of complete machine tool products, and takes winning customers'touching as its business goal.

Exhibit brands

Exhibits

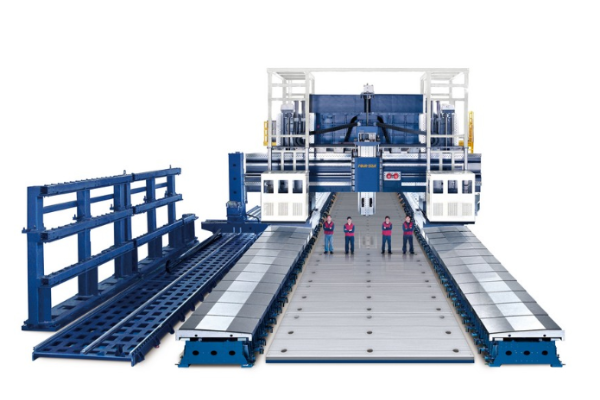

SDW Moving-column Moving-beam Gantry Processing Machine and Gantry Milling Machine

Super rigid structure design; high speed, high precision, high efficiency, the whole machine structure adopts all castings in the box, which resists temperature and improves shock resistance; the center of the main shaft passes through the center of gravity of the whole machine, which improves the dynamic and static rigidity and stability; the center of the main shaft is close to the column track, which can stabilize the counterweight to meet various processing rigidities; for the size and processing specifications of the machine, the three-axis track is combined with different line tracks; Aim at different processing requirement of part processing or mold processing, different main shaft transmission systems are match; that crossbeam adopts double servo synchronous positioning at any position;

.png)

Moving column gantry machining center (SD series)

Super rigid structure design; high speed, high precision, high efficiency, the whole machine structure adopts all castings in the box, which resists temperature and improves shock resistance; the center of the main shaft passes through the center of gravity of the whole machine, which improves the dynamic and static rigidity and stability; the center of the main shaft is close to the column track, which can stabilize the counterweight to meet various processing rigidities; for the size and processing specifications of the machine, the three-axis track is combined with different line tracks; Aim at different processing requirement of part processing or mold processing, different main shaft transmission systems are match; that crossbeam adopts double servo synchronous positioning at any position;

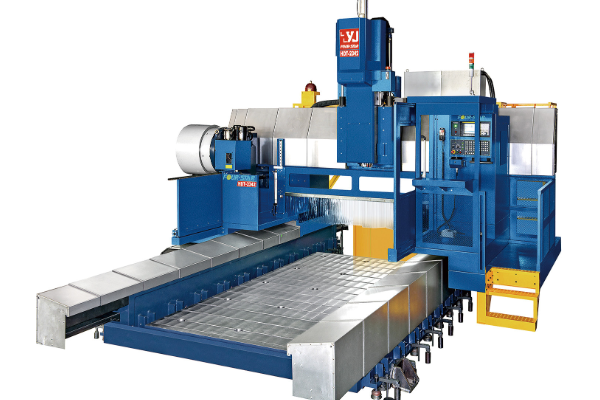

FDW fixed column moving beam gantry processing machine, gantry milling machine

Super rigid structure design; high speed, high precision, high efficiency, the whole machine structure adopts all castings in the box, which resists temperature and improves shock resistance; the center of the main shaft passes through the center of gravity of the whole machine, which improves the dynamic and static rigidity and stability; the center of the main shaft is close to the column track, which can stabilize the counterweight to meet various processing rigidities; for the size and processing specifications of the machine, the three-axis track is combined with different line tracks; Aim at different processing requirement of part processing or mold processing, different main shaft transmission systems are match; that crossbeam adopts double servo synchronous positioning at any position;

.png)

Fixed column gantry processing machine (FD series)

Super rigid structure design; high speed, high precision, high efficiency, the whole machine structure adopts all castings in the box, which resists temperature and improves shock resistance; the center of the main shaft passes through the center of gravity of the whole machine, which improves the dynamic and static rigidity and stability; the center of the main shaft is close to the column track, which can stabilize the counterweight to meet various processing rigidities; for the size and processing specifications of the machine, the three-axis track is combined with different line tracks; Aim at different processing requirement of part processing or mold processing, different main shaft transmission systems are match; that crossbeam adopts double servo synchronous positioning at any position;

GM crown block gantry processing machine, crown block gantry milling machine

Super rigid structure design; high speed, high precision, high efficiency, the whole machine structure adopts all castings in the box, which resists temperature and improves shock resistance; the center of the main shaft passes through the center of gravity of the whole machine, which improves the dynamic and static rigidity and stability; the center of the main shaft is close to the column track, which can stabilize the counterweight to meet various processing rigidities; for the size and processing specifications of the machine, the three-axis track is combined with different line tracks; Aim at different processing requirement of part processing or mold processing, different main shaft transmission systems are match; that crossbeam adopts double servo synchronous positioning at any position;

HDT High Efficiency Active Column Milling Machine

Super rigid structure design; high speed, high precision, high efficiency, the whole machine structure adopts all castings in the box, which resists temperature and improves shock resistance; the center of the main shaft passes through the center of gravity of the whole machine, which improves the dynamic and static rigidity and stability; the center of the main shaft is close to the column track, which can stabilize the counterweight to meet various processing rigidities; for the size and processing specifications of the machine, the three-axis track is combined with different line tracks; Aim at different processing requirement of part processing or mold processing, different main shaft transmission systems are match; that crossbeam adopts double servo synchronous positioning at any position;

Main products

Main products: fixed column gantry processing machine (FD series), moving column gantry machining center (SD series), FDW fixed column moving gantry processing machine, gantry milling machine, SDW moving column moving gantry processing machine, gantry milling machine, FQ high-speed high-precision fixed column gantry processing machine, gantry milling machine, GM crane gantry processing machine, crane gantry milling machine. HDT high efficiency moving column gantry milling machine, HRP high rigidity and high precision moving column gantry processing machine, horizontal boring and milling machine