Company Introduce

Guangdong Machinery Research Institute Co., Ltd., founded in 1960, is a high-tech enterprise, a wholly-owned state-owned enterprise under Guangdong Environmental Protection Group Co., Ltd. and Guangdong Guangye Equipment Manufacturing Group Co., Ltd. The company, formerly known as Guangdong Academy of Mechanical Sciences, is a provincial-level scientific research institution. In 1978, it was renamed Guangdong Machinery Research Institute, directly under the management of Guangdong Machinery Industry Department. In July 2020, the company was restructured and renamed as Guangdong Machinery Research Institute Co., Ltd. According to the national and local development strategies, industry needs and market demand, the company continuously deepens the system reform, forms a market-oriented operation mechanism, and enhances the core competitiveness of enterprises. The company has been engaged in the research and application of advanced manufacturing technology, is the main birthplace and disseminator of CAD/CAM/CAE technology in Guangdong Province, and has a high-quality research and development and industrialization talent team. It has successively won the honors of state-level high-tech enterprises, provincial enterprise technology centers of Guangdong Province, engineering technology research centers of Guangdong Province, state-level science and technology business incubators, the second batch of ecological partners of intelligent manufacturing in Guangdong Province, specialized, special and new small and medium-sized enterprises in Guangdong Province, and intellectual property demonstration enterprises in Guangdong Province. More than 200 major scientific research projects have been completed, of which more than 80 have been awarded by government departments at or above the provincial level. It has obtained more than 100 patents and software copyrights authorized by the state.

Exhibit brands

Exhibits

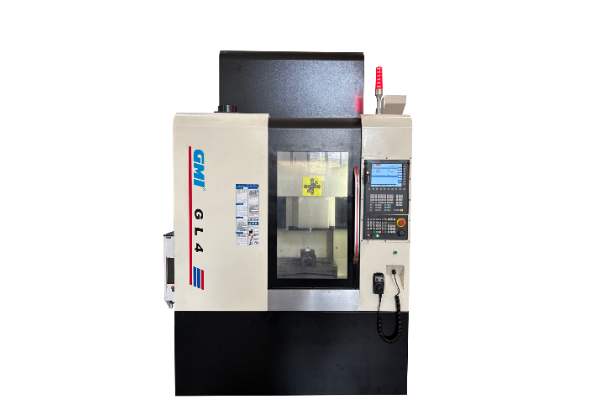

GL4 High Speed Linear Motor Machining Center

1. Three-axis application of the industry's latest linear motor technology, high-precision linear grating ruler for full closed-loop control. Compare with that traditional screw rod transmission mode, the invention has no mechanical contact and reverse clearance, solves the problem of thermal elongation, quick wear, short service life and the like of the screw rod, has higher dynamic characteristics and acceleration, and realizes high speed, high precision and high finish. 2. The bed base is made of advanced mineral casting, namely artificial stone material, which has excellent damping performance, low thermal conductivity, long-term stability of precision and high corrosion resistance. The performance and stability of the whole machine are much higher than those of the traditional cast iron structure machine tool. 3. Intelligent automatic washing system for bed. 4. Patented design of multi-layer sealing protection ensures the maximum service life of linear motors, guide rails and other important components. 5. Equipped with FANUC CNC system with powerful automation technology and excellent performance, durable operation panel, simple and convenient operation, excellent surface function can obtain the best workpiece surface. 6.20 high-speed servo tool magazine, specially designed with two layers of protection to prevent iron pollution. 7. Linear motor drive, repeated positioning accuracy up to 0.002 mm. 8. High rigidity flange type high precision permanent magnet synchronous electric spindle, high speed, high precision, high stability, extremely low thermal elongation, more suitable for high-speed and high-precision machining. 9. Strict production and inspection process, strict laser interference, ball bar instrument testing, to ensure the quality of each machine. 10. Four-axis or five-axis turntable can be installed to realize multi-axis linkage processing. 11. Finite element analysis to ensure the best mechanical and modal structure.

K6S High Speed Graphite Machining Center

1. Initiated in the domestic industry, the bed base is made of high-quality mineral casting (artificial stone) material, which has excellent damping performance, low thermal conductivity, long-term stability of precision and high corrosion resistance. The performance and stability of the whole machine are much higher than those of the machine tool with traditional cast iron structure. 2. Compact twin-screw automatic chip and powder removal, wet processing equipped with automatic bed cleaning system, dry graphite processing optional equipped with highly integrated graphite dust recovery system. 3. The patented design of multi-layer sealing protection of the screw guide provides a strong guarantee for the maximum service life of the screw guide.

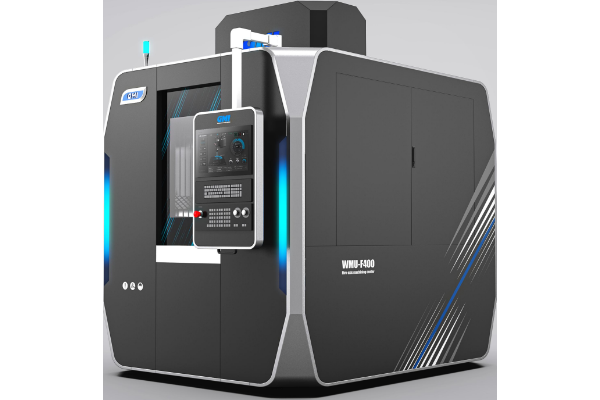

F400 5-axis machining center

1. Crane structure design, moving parts away from the cutting area, effectively reduce the failure rate of moving parts. 2. Integral cradle AC structure and roller cam/DD motor structure ensure that the operator is closest to the milling head and the workbench, which is convenient for manual tool change and workpiece clamping, reduces the labor intensity of the operator to the greatest extent and improves the productivity. 3. Fully enclosed protection design, effectively protect the screw guide rail, prolong the service life of the machine tool; 4. Servo tool magazine, reliable tool change; automatic compensation of tool setting instrument, greatly improve productivity. 5. Precision high-speed spindle, equipped with precision spindle oil cooler, to keep the spindle temperature constant and reduce the processing error caused by temperature rise. 6. It has five-axis linkage (RTCP) tool tip following processing function and bevel processing function (G68.2 command function). 7. Taiwan/Europe imported precision ball screw, P linear guide. 8. Strict production and inspection process, strict laser interference, ball bar instrument testing, to ensure the quality of each machine.

Main products

It provides intelligent manufacturing equipment for precision machine tools, traditional Chinese medicine, automotive electronics, electrical machinery and other industries. Including five-axis machining center, graphite machining center, linear motor machining center, gantry machining center, horizontal/vertical machining center, as well as traditional Chinese medicine equipment, traditional Chinese medicine decocting center and automatic intelligent pharmacy construction, industrial robot integrated application, digital intelligent factory overall solution, as well as industrial automation non-standard and standardized equipment R & D, production and sales.