Company Introduce

Founded in 2006, Guangdong Qunhui Protection Technology Co., Ltd. has been committed to the research of "better use" machine tool protective cover technology for many years, and the machine tool protective cover produced by the company is famous for its "high quality" in the industry. R & D capability: It has 24 engineers and technicians, 6 expert teams, and has obtained 6 national invention patents. Production capacity: It has a professional dust-free workshop of more than 10000 square meters, two automatic production lines of Italian organ type protective cover, two production lines of guide rail telescopic protective cover, two production lines of sheet metal outer cover, one production line of chip removal machine, and one automatic paint baking line. Production equipment: TRUMPF laser cutting machine imported from Germany with original packaging, automatic welding equipment for protective cover from Italy, CNC turret punch, CNC bending machine, CNC plate shearing machine, CNC lathe, CNC milling machine, paint baking equipment, tensile testing machine, reciprocating testing machine, etc. Quality assurance capability: The company has passed ISO9001: 2008 quality system certification

Exhibit brands

Exhibits

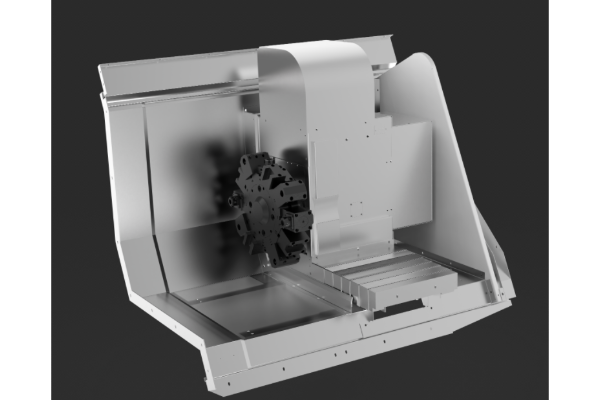

Full protective cover for lathe

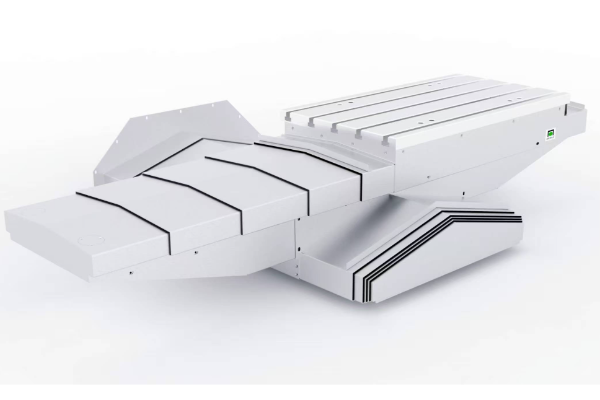

Steel plate telescopic shield

Protection in machining center

The ratio of the width to the length after compression should not exceed 3.5: 1, otherwise it is difficult to avoid skew or jamming during expansion and contraction. Each protective cover can not only move together, but also move smoothly and in parallel at high speed. There is no vibration, so the noise is very low. The use of this type of protective cover can prolong the service life of the machine.

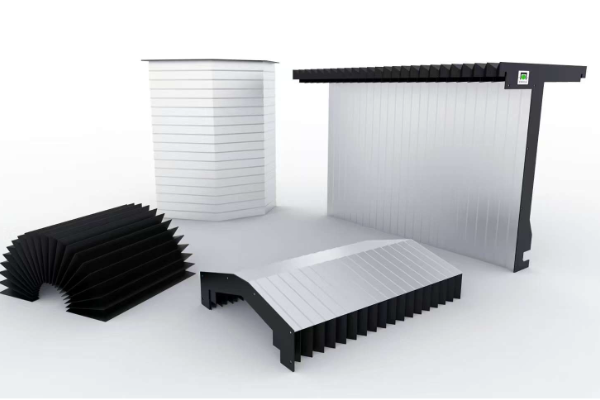

Armor shield

Each folded layer of the armor-type stainless steel machine tool protective cover can withstand strong vibration without deformation, and at the same time, it is applied to the bellows at a high temperature of 900 ℃ and still maintains its original state. They support each other and play a role in preventing the penetration of small debris.

Main products