.png)

Company Introduce

Wentao is a high-tech enterprise integrating independent research and development, production, sales and service. Founded in 2014, Wentao mainly produces on-machine measurement products such as machine tool automatic tool setting instrument and workpiece measuring head. The company's products are based on the machinery manufacturing and processing industry, and the market share of domestic brands in the field of machine measurement is far ahead, which has been praised by all manufacturers in the industry! Through nearly ten years of development, it has more than 6000 square meters of factory buildings, complete independent production equipment, various technical personnel and excellent after-sales service team, and has a number of invention patents and utility model patents. As always, the company adheres to the principle of "quality first, service first", and contributes its strength to the domestic measurement products going to the world!

Exhibit brands

Exhibits

Contact tool setting instrument

It is used for online detection of tool length, wear and breakage of CNC machine tools, and automatic compensation.

Infrared probe

1, accurate measurement, alignment of the workpiece position, automatic correction of the coordinate system 2. Quickly align the position of the fixture and reduce the manual adjustment time 3. Simplify the fixture design and reduce the fixture cost 4. Carry out on-machine measurement and inspection of the first article without offline. 5. Improve the consistency of productivity and batch processing size 6. Measure in cycle processing, monitor the size and position of the workpiece, and automatically correct the deviation value. 7. Shorten the auxiliary time of machine tool and improve the production efficiency

Lathe tool setting arm

It is used for tool measurement and tool breakage detection on two-axis or three-axis CNC lathes.

Laser tool setting instrument

For non-contact physical dimension measurement and tool detection

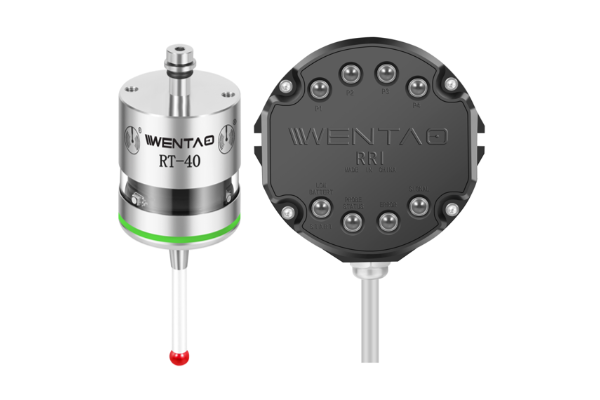

Radio probe

1, accurate measurement, alignment of the workpiece position, automatic correction of the coordinate system 2. Quickly align the position of the fixture and reduce the manual adjustment time 3. Simplify the fixture design and reduce the fixture cost 4. Carry out on-machine measurement and inspection of the first article without offline. 5. Improve the consistency of productivity and batch processing size 6. Measure in cycle processing, monitor the size and position of the workpiece, and automatically correct the deviation value. 7. Shorten the auxiliary time of machine tool and improve the production efficiency

Contact tool setting instrument

It is used for online detection of tool length, wear and breakage of CNC machine tools, and automatic compensation.

Main products

Tool detection instrument: laser tool setting instrument, automatic tool setting arm, contact tool setting instrument; Workpiece measuring instruments: infrared probe, radio probe, wired probe.