Company Introduce

Metal steel belts feature exceptional durability, high precision, cleanliness, corrosion resistance, and heat resistance, enabling applications that cannot be achieved with resin or rubbger belts. They are widely used in power transmission and inspection or transportation processes for robotics, pharmaceutical and food production lines, solar cell module interconnection, as well as coating and cutting processes for battery electrodes. For over 40 years, Dymco has specialized in the design, manufacture, and sales of precision stainless steel belts and related equiment. Our products hold a leading position in Japan and are trusted by many major Japanese manufacturers. We supply steel belts, steel belt conveyors, vacuum conveyors, and double-layer conveyors designed for high-temperature and high-pressure environments. In addition, Dymco products are delivered worldwide, including China, the United States, Germany, Switzerland, Italy, the Netherlands, Turkey, Poland, France, India, and South Korea. Dymco uses carefully selected high-wear, high-tensile steel materials and advanced welding technologies, including seamless welding, to ensure flat joints with uniform thickness and strenth. Surface treatments such as heat resistance, non-stick properties, and low reflectivity can be applied according to customer requirements. We also design and manufacture burr-free precision perforated belts, ideal for high-speed, deformation-free conveyance of lightweight and thin materials such as battery electrode films. With the precision and reliability of Japanese craftsmanship, Dymco's stainless steel belts help your production stand out from the competition.

Exhibit brands

Exhibits

SCARA Robot Demonstration

• This demonstration unit allows for intuitive visualization of the steel belt’s actual installation method, operating conditions, and tensioning state. • It helps customers gain a clearer understanding of the product’s characteristics and provides strong support for selection and evaluation.

Open-End Belt

• Quick response for driving • High rigidity and high tensile strength • Very small elongation • Excellent heat and corrosion resistance • Fairly small backlash • Thin, compact, and lightweight

Welded Endless Belt

• Excellent surface smoothness • Ridge of weld line is minimal with 10-micron order • Chemical and heat resistant • Low dust generation, ideal in clean rooms • High electric conductivity with antistatic property

Perforated Belt

• Suction holes for vacuum operation • Positioning holes for intermittent feed and mechanical attachments • Various hole options • Perforated belt after welding has excellent surface flatness

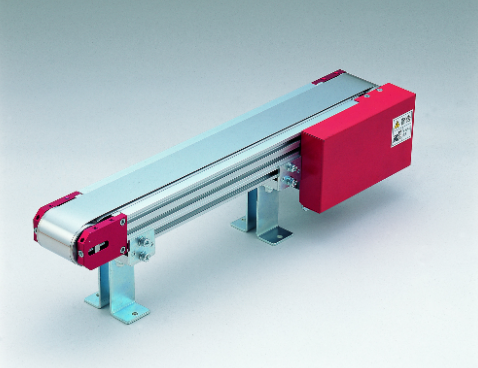

Stainless Steel Belt Conveyor

• High tensile stainless steel belt installed • Smooth belt surface • Lightweight with aluminum frame • Easy-to-install and maintenance-friendly • Positioning-free insertion nuts offer easy installation of custom made-jigs • Heat Resistance, corrosion resistance, antibacterial

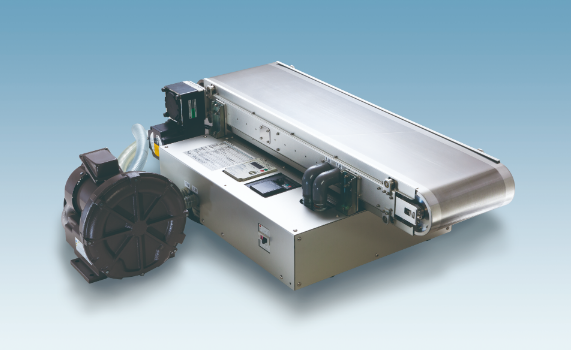

Vacuum Conveyor

• The steel belt with arrayed thin holes moves on a suction chamber. Position of the objects on the belt is being secured by the air flow, and flexible materials are flattened during transportation. • Up and down movement of belt surface is limited. 0.08mm by the conveyor in the picture below. • This conveyor system provides an adequate environment for the printing on the belt because of the very small elasticity of steel belt. • When the belt is coated by PTFE, wiping contaminations like ink, pigments, dye etc. off the belt is very easy. • The steel belt has the nature of strong resistance to abrasion. • Curled paper and plastic films can be flattened by applying suction air flow in the entire area.

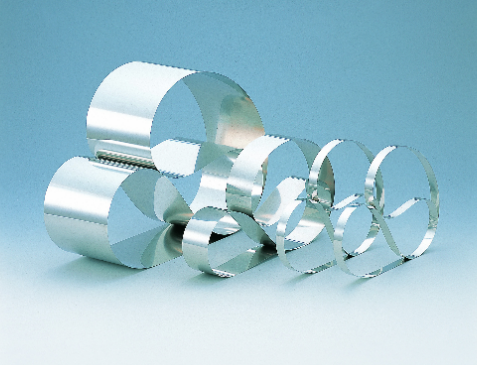

Main products

・Design, manufacture, and sales of steel belts (metal belts) and related equipment (including steel belt reducers and steel belt conveyors) ・Design, manufacture, and sales of precision mechanical components ・Manufacture and sales of ultra-thin metal sleeves ・Sales of pumice polishing materials (silica-based)