Company Introduce

Founded in 1979, FFG has established three business groups based on the concept of honesty, responsibility and sustainable operation: (1) Machine Tool Business Group. (2) Industrial equipment business group. (3) Green energy business group. Among them, the machine tool business group is the main body, accounting for more than 60% of the group's revenue. In 1985, the Group's Machine Tools Division began to market its self-created FEELER brand at home and abroad. In the machine tool business group, there are 37 machine tool brands and 50 production bases, and they are distributed in the 13 largest machinery manufacturing countries and regions in the world, including China, Taiwan, the United States, Germany, Japan and Italy. It is one of the largest vertical machining center manufacturer groups in the world.

Exhibit brands

Exhibits

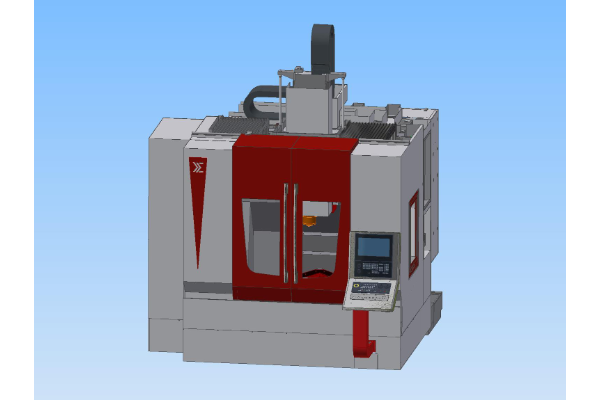

Youhuai DMX-800A

DMX-800A 1. Whether it is precision parts processing or general mold processing, Youjia's new generation of DMX series vertical machining centers will provide you with impeccable performance. It adopts high-grade cast iron engine body, which is analyzed and designed by ANSYS and NASTRAN. The column "A" shape is strengthened to match the super-large base, and its high rigidity structure ensures long-term stability and accuracy. Equipped with 12000 RPM spindle to meet high surface quality requirements, it is an ideal tool to improve precision machining capacity and quality. 2. The fuselage and castings are made of high-grade Mihanna cast iron, which is stable and deformation-resistant. The main structure is designed by ANSYS/NASTRAN finite element analysis to ensure the best rigidity and stability. 3. The rigidity of the integrated main shaft head is increased by about 5%, the main shaft roller rail achieves high speed and high rigidity, and the bottom of the column is strengthened in the shape of "A". 4. The Z-axis stroke is expanded to 600 mm, the standard 12000 rpm direct-connected spindle is equipped, and the maximum load of the workbench can reach 1200 KG. 5. Excellent fuselage structure with high-speed servo transmission system, X/Y/Z axis fast movement up to 48m/min; The ball screw is directly driven by the same motor to ensure the rigidity and precision of the feed transmission system.

Youjia SMG 1100

Youjia SMG1100 1. High rigidity. Back wall type gantry structure is adopted. The spindle moves in the X/Z direction. The high-rigidity sliding seat and ram combination adopts a low overhang structure, which greatly reduces the influence of structural deformation on processing, and the whole stroke range is fully supported to ensure good rigidity. The integrated structure of column and beam ensures the minimum Z-direction error during machining load, and has better response characteristics to Y-direction cutting force. The worktable only moves in the Y direction and is supported in full stroke, and there is no eccentric load on the worktable. 2. High speed and high precision. The high rigidity structure is combined with linear motor drive and high precision grating ruler to realize high speed and high precision processing. The fast moving speed can reach 60m/min, and the acceleration can reach 1G. Compared with the traditional screw structure, the linear motor has high responsiveness and no influence of the temperature rise of the screw, thus realizing high-precision processing. The linear motor is equipped with a full-specification cooling system to reduce the impact of motor heating. 3. High-power and high-torque electric spindle, 16000 rpm, 18kW.

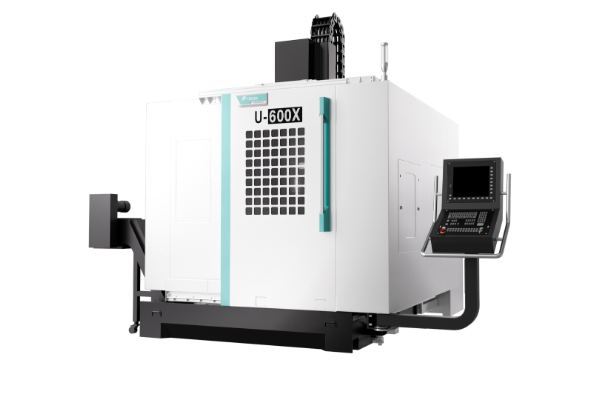

Youjia U600X

Youjia U600X 1. The processing workpiece generates reaction force, which is transferred to each shaft structure to generate load bearing. The suspension mechanism of the moving shaft will also produce load. The structure of U-250 has three wheels without suspension, thus avoiding the load of each axle and maintaining the accuracy more effectively. And 2, that heavy cut also realizes high rigidity and high precision: the three-axis stac full-motion column design does not generate deformation when the X axis and the Y axis move. The resuspension distance between the spindle and the Z axis is extremely short, and the load changes during the movement are extremely low, providing good dynamic accuracy. And 3, the double-side constraint cutter adopts a double-side constraint cutter system, and the closer cutter supports the solid surface to provide more dynamic rigidity and stable precision. The water outlet device in the center of the main shaft improves the deep hole processing capacity, and the cooling water tank is forced to pass through the main uranium center and the cutting tool to reach the cutting point. Roller Guide Roller guides are used for each axis movement to provide better rigidity and reliability.

Liwei DL600GBII

Liwei DL600GBII 1, DMC's DL GB series is the best equipment for grinding and machining quartz and ceramic material components, providing a high quality finish. 2. High-strength structural integrated bed. Minimization of complex thermal displacement by 45 ° inclined integrated high rigidity bed structure High precision feed system, high stability, hard rail for all axes X-axis grinding load reduction of 53%: 2.14 Nm 3. High-precision spindle equipped with high-power motor adopts angular contact ball bearing and standard spindle blowing dust-proof and coolant leakage structure. 170 L coolant tank with the largest dedicated coolant fan in its class as standard (sediment inducement).

Main products

CNC machine tool