Company Introduce

Fujian Jorent Intelligent Manufacturing Precision Machinery Co.,Ltd. was established in 2019, with a plant area of 3,300 square meters and total asset capital of 15 million yuan. It is a company that integrates design and precision processing and committed to a variety of precision hardware and mechanical parts of the trial and mass production, including aerospace machinery parts, optical lens structure parts, car lens machinery parts, as well as medical equipment, sheet metal bending, automobile parts, and anodizing. The company has production equipment and precision testing instruments from the United States, Germany and Japan. The number of machines reaches 63 sets, 12 sets are measuring instruments with the highest detection precision reaches 1um. The company has the integrated process system from designing, manufacturing to testing, and passed the ISO9001 quality management system certification.The company has nearly one hundred professional technicians with rich experience in precision machining, and is committed to providing customers with high-quality products and services. The company has perfect pre-sales technical support, with efficient production delivery and after-sales technical service team, can provide customers with safe, reliable, high quality and efficient customized precision machining solutions.

Exhibit brands

Exhibits

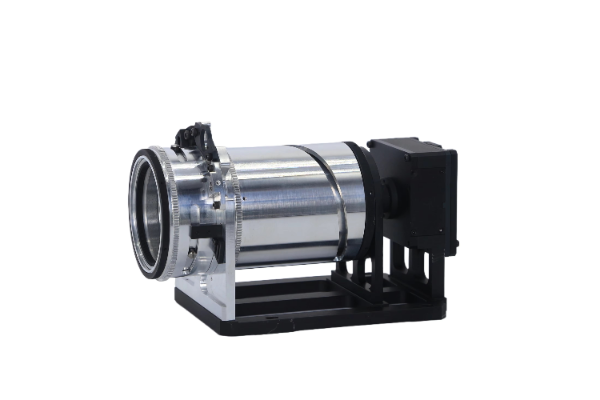

Precision Lens Mechanical Assembly

This product is a precision mechanical assembly for industrial camera lenses, integrating lens barrel, mounting flange and motorized drive to achieve accurate lens positioning and autofocus/zoom, suitable for machine vision and inspection systems.

Len barrel assembly of optical len

This product is a precision lens barrel component for optical lens assemblies, providing accurate mounting and support for multiple lens elements to ensure coaxial alignment and stable imaging. It is manufactured from high‑precision machined metal materials and can be customized to match various industrial camera, projection or machine vision interfaces

Flange‑mounted Precision Lens Barrel

This product is a flange‑mounted precision lens barrel for optical lens assemblies, providing rigid connection between the lens and the system frame or optical engine, and ensuring accurate coaxial alignment of lens elements. It is integrally machined from high‑strength aluminum alloy with high dimensional accuracy and rigidity, making it suitable for industrial cameras, projection optics and precision inspection equipment.

Zoom & Focusing Cam Tube

This product is a helical cam lens barrel used in zoom and focusing mechanisms. Precision helical cam slots are machined on the outer surface of the tube, allowing cam followers or bearings to travel along the slots and drive lens groups to move linearly along the optical axis. The part is CNC‑machined from aluminum alloy with a matte black finish, providing smooth motion, high positioning accuracy and a compact structure for use in projection lenses, machine vision lenses and other precision zoom optics.

Precision Optoelectronic Enclosure Assembly

This product is an integrated opto‑mechanical housing and base for optoelectronic equipment. The upper cavity is designed to mount lenses, optical components and drive mechanisms, while the lower enclosure provides space for electronic boards and control modules, enabling precise system assembly and reliable protection. It is machined from high‑strength aluminum alloy with anti‑corrosion surface treatment, offering high dimensional accuracy, structural rigidity and good thermal performance, and is suitable for high‑end inspection instruments, imaging optics and industrial sensing devices.

Machine Vision Industrial Lenses

This product series consists of machine vision lenses for industrial cameras, including both fixed‑focal and zoom models with standard C‑mount and other interfaces. The lenses feature low‑distortion optical design with precise focus and zoom mechanisms, providing high‑resolution, high‑contrast imaging for automated inspection, measurement, identification and positioning applications.

Flange‑Mounted Opto‑Mechanical Components

This product series consists of large‑aperture flange‑mounted opto‑mechanical components, including lens barrels, mounting flanges and baffle assemblies for precise alignment of optical assemblies to system frames or optical engines. All parts are integrally machined from metal such as aluminum alloy and connected via bolted flanges, providing high dimensional accuracy, good coaxiality and convenient installation and maintenance for projection optics, inspection equipment and other precision optoelectronic systems.

Color Anodized Lens Barrel Components

This product series consists of color anodized aluminum lens barrel and housing components for optical and optoelectronic systems. The parts are CNC‑machined from aluminum alloys and finished with multi‑color anodizing, providing an attractive appearance together with excellent corrosion and wear resistance, and can be customized in dimensions, tolerances and colors for use as outer lens barrels, protective housings and other precision opto‑mechanical structures.

Precision Aluminum Support Frames

This product series consists of precision aluminum mounting brackets and support frames for control boards and opto‑mechanical modules. The parts are CNC‑machined from aluminum alloys to provide lightweight yet rigid structures with multiple mounting holes and reference surfaces for accurate positioning and reliable fixation of PCBs, sensors and optical assemblies, suitable for industrial control equipment, machine vision systems and other precision optoelectronic devices.

Main products

including aerospace machinery parts, optical lens structure parts, car lens machinery parts, as well as medical equipment, sheet metal bending, automobile parts, and anodizing.