Company Introduce

Founded in 2023, Ruishengchang Aluminum (Guangdong) Co., Ltd. is affiliated to Ruishengchang Group. It is a modern enterprise with aluminum processing, sales and distribution as its core industries. It is committed to providing integrated service providers of various high-quality aluminum alloy sheets, bars and profiles for intelligent manufacturing, mechanical processing and other industries. Founded in 2007, Ruishengchang Group strictly implements the 6S management system, and passed the ISO9001 international quality management system certification and GJB9001B-2009 national military standard quality management system certification in 2014. With advanced production technology and equipment and a multi-functional laboratory, it provides customers with reliable product quality assurance, can produce 5 series, 6 series wiredrawing aluminum plates, iron panels and other high-precision plates, and also cooperates with well-known aluminum processing enterprises at home and abroad, standing 1 series, 2 series, 5 series, 6 series, 7 series plates, bars and other spot stocks of more than 10000 tons, customer groups radiate the whole country. Products are exported to Europe, America and Southeast Asia and other countries. We will adhere to the enterprise spirit of "Ruixing has a way, and everything is prosperous", follow the values of "hard work, self-criticism, openness and progress, sincerity and trustworthiness, teamwork and mutual achievement", practice the concept of "meeting customer needs as the guide", adhere to the enterprise vision of "integrating global high-quality aluminum resources, serving national industry", develop continuously and contribute to social development. Ruishengchang is willing to cooperate with you wholeheartedly, develop together and create a better tomorrow hand in hand.

Exhibit brands

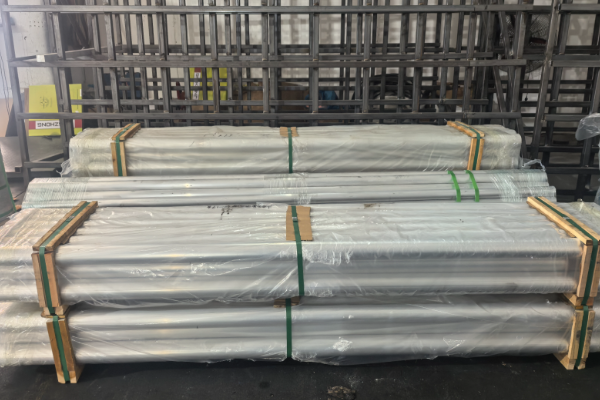

Exhibits

6061 aluminum plate

6061 is a kind of Al-Mg-Si alloy with medium strength, good plasticity and corrosion resistance, especially no stress corrosion cracking tendency, good weldability, corrosion resistance and cold workability, which is a promising alloy with wide application range. It can be anodized and colored, and can also be painted with enamel, which is suitable for building decoration materials; It contains a small amount of Cu, so its strength is higher than that of 6063, but its quenching sensitivity is also higher than that of 6063. After extrusion, it can not be air-quenched, and it needs re-solution treatment and quenching aging to obtain higher strength.

6061 aluminum rod

6061-T651 aluminum bar is the main alloy of 6 series alloy, which is a high-quality aluminum alloy product after heat treatment and pre-stretching process; Although its strength can not be compared with 2 series and 7 series, its magnesium and silicon alloy has many characteristics, such as excellent processing performance, excellent welding characteristics and electroplating, good corrosion resistance, high toughness, no deformation after processing, dense and defect-free material, easy polishing, easy coloring film, excellent oxidation effect and so on.

6061 forgings

6061 aluminum sheet can be processed into plates, tubes, bars, shapes, wires and forgings; it can also be used as building materials, large structures requiring good corrosion resistance, structural parts of trucks, ships and railway vehicles, conduits, furniture and decorative materials, etc.

7075 aluminum plate

7075 aluminum plate is a cold-forged alloy with high strength and hardness, far superior to mild steel. 7075 aluminum sheet is one of the strongest commercially available alloys, with general corrosion resistance, good mechanical properties and anodic reaction. Fine grain makes the deep drilling performance better, the tool wear resistance is enhanced, the thread rolling is more distinctive, and the preferred metal material with lower density requirements and higher hardness requirements.

7075 aluminum rod

7075 aluminum is known as ultra-high strength aluminum alloy. The yield strength of the alloy is close to the tensile strength, the yield ratio is high, and the specific strength is also very high, but the plasticity and high temperature strength are low. It is suitable for load-bearing structural parts used at room temperature and below 120 ℃. The alloy is easy to process and has good corrosion resistance and high toughness. The alloy is widely used in the field of aviation and aerospace and becomes one of the most important structural materials in this field.

7075 forgings

7075 aluminum forgings are high-strength and lightweight metal parts made of 7075 aluminum alloy through forging process. Its core characteristics include tensile strength ≥ 560MPa and density 2.81 G/cm ³. It is widely used in aerospace, automotive and high-end equipment fields.

Non-standard 6061 aluminum bar

6061 non-standard aluminum bar is a kind of rectangular aluminum material made of Al-Mg-Si 6061 alloy, which has the characteristics of good comprehensive performance, moderate strength, strong corrosion resistance, excellent processing and welding performance, etc. Its main components include magnesium (Mg) and silicon (Si), and high strength can be obtained by heat treatment such as T6 or T651. The product has a density of about 2.73 G/cm ³ and good conductivity, and is commonly used in mechanical structural parts, automotive parts, electrical busbars, automation equipment, rail transit and other fields. The surface can be anodized to enhance aesthetics and protection. This product is easy to cut, drill and bend, and is a general purpose industrial aluminum material with wide application.

Main products

GB 6061 Aluminum Plate, Aluminum Bar and Forging GB 7075 Aluminum Plate, Aluminum Bar and Forging Non-standard 6061 aluminum bar