Company Introduce

Founded in 2008, Super Synchronous Co., Ltd. focuses on the field of intelligent manufacturing, providing servo motors, torque motors, electric spindles and other core components and professional automation servo control solutions. The company has two wholly-owned subsidiaries, Beijing Super Synchronous Technology Co., Ltd. (Established in 2000) and Shandong Super Synchronous Intelligent Equipment Co., Ltd. (Established in 2017). The company is a national high-tech enterprise, a national specialized and new "Little Giant" enterprise, and a new three-board listed enterprise. The company has been recognized as "National Green Factory" and "Intelligent Factory" in Beijing. The company is a patent demonstration unit in Beijing, a scientific and technological research and development institution in Beijing, and an enterprise technology center in Beijing. The company's products include a full range of AC servo motors, AC servo drivers, PLC, motion controllers and other industrial automation products, torque motors, electric spindles, direct-drive rotary tables and other core functional components, five-axis vertical machining centers and other high-end intelligent equipment. Its core technology has reached the international advanced level, and its key products can replace imported similar products, which are widely used in industrial mother machines, industrial robots, industrial automation and other fields. The company has core technologies with independent intellectual property rights, more than 300 patents and software copyrights, including more than 30 invention patents. The servo control system technology is in the leading position in China. It has mastered core technologies such as servo control space vector algorithm, control software development, servo drive design, servo motor electromagnetic design and manufacturing process. The company has two intelligent equipment industrial parks in Beijing and Shandong, covering an area of 100000 square meters.

Exhibit brands

Exhibits

Z18 Series AC Induction Servo Motor

Product features: beautiful appearance, exquisite structure, low noise, high efficiency, closed cooling duct, optimized energy-saving design Standard spindle control functions: low-speed high-torque cutting, zero-speed spindle locking, C-axis function, high-speed constant power cutting, quasi-stop control, rigid tapping Industry application: CNC lathe, turning and milling machine tool, vertical lathe, heavy horizontal lathe, CNC milling machine, vertical machining center, horizontal machining center, CNC boring machine, gantry planer, gantry milling machine, CNC grinder, vertical grinder, floor boring and milling machine, drilling and tapping center, engraving and milling machine, gear hobbing machine, gear shaper, gear milling machine

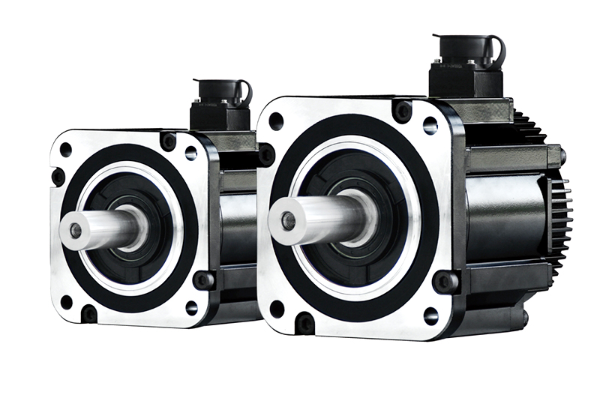

S18 Series Permanent Magnet Synchronous Servo Motor

Built-in high-precision absolute encoder improves positioning accuracy and low-speed operation stability. And can be control with high precision and high dynamic response. The motor is designed with low cogging force to achieve smooth operation. The torque ripple of the motor is reduced by using a new magnetic field analysis design and motor processing technology, thus improving the speed stability and reducing the torque ripple of the servo system. The stator of the servo motor adopts a new lamination and splicing process, which reduces the temperature rise of the motor, improves the electromagnetic characteristics of the motor, and improves the efficiency and reliability.

Electric spindle of milling machine

It is driven by a high-efficiency asynchronous built-in motor, and the rotor is made of cast copper, with high power, low heat and high efficiency. Ceramic angular contact ball bearings are used, with low heat, low thermal expansion coefficient and high speed. The pre-tightening mode mainly adopts positioning pre-tightening and constant pressure pre-tightening. Positioning pre-tightening can meet the requirements of high rigidity and large torque, and constant pressure pre-tightening can meet the requirements of ultra-high speed. Dynamic balance correction is within G1. Low noise and small thermal deformation. And that dynamic rotation precision is high. Tool internal cooling, temperature sensor and vibration sensor are optional.

Lathe electric spindle

It is driven by permanent magnet synchronous built-in motor with small volume and high power density. Bearing pre-tightening mainly adopts positioning pre-tightening, which can meet the requirements of high rigidity and large torque. Dynamic balance correction is within G1. Low noise and small thermal deformation. And that dynamic rotation precision is high. The built-in locking mechanism can realize high torque locking without changing the accuracy during locking.

HOST50 CNC system

HOST50 CNC system is a bus-type all-digital CNC device, which supports EtherCAT bus protocol and has technologies such as multi-axis multi-channel control, high speed and high precision, composite processing technology and multi-axis group synchronous control. The system adopts acceleration and deceleration control algorithm, small line processing control algorithm and cubic spline interpolation algorithm, which can meet the control requirements of high speed and high precision. The product can be applied to aerospace, automobile manufacturing, energy and power, metal mold, 3C and other industries, providing efficient and accurate motion control and process solutions for various industries.

Main products

Full range of AC servo motor, AC servo driver, PLC, motion controller and other industrial automation products, torque motor, electric spindle, direct-drive turntable and other core functional components, CNC system and other products.